Energy-saving quartz continuous melting furnace, energy-saving method and method for adjusting tube pulling specification

A technology of continuous furnace and quartz, applied in the field of energy-saving quartz continuous furnace and adjustment of drawing tube specifications, can solve the problems of reducing production capacity, increasing the frequency of furnace shutdown, and small adjustable specifications of drawing tubes, so as to maintain the temperature in the furnace and expand the adjustment range. , the effect of shortening the baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

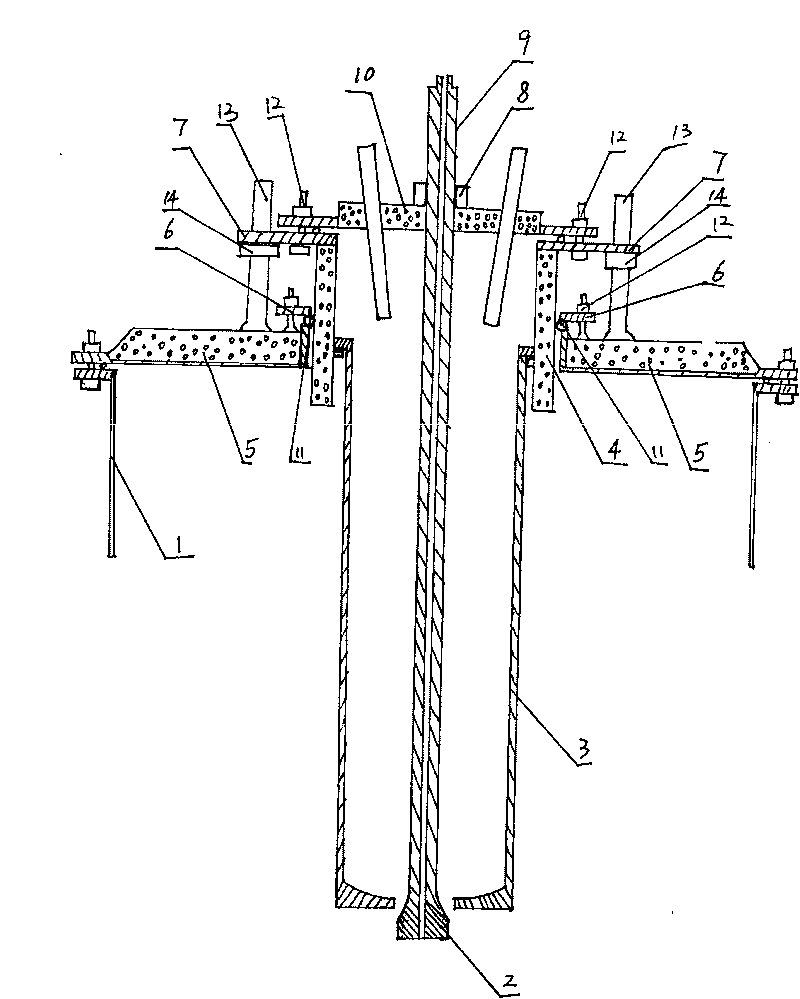

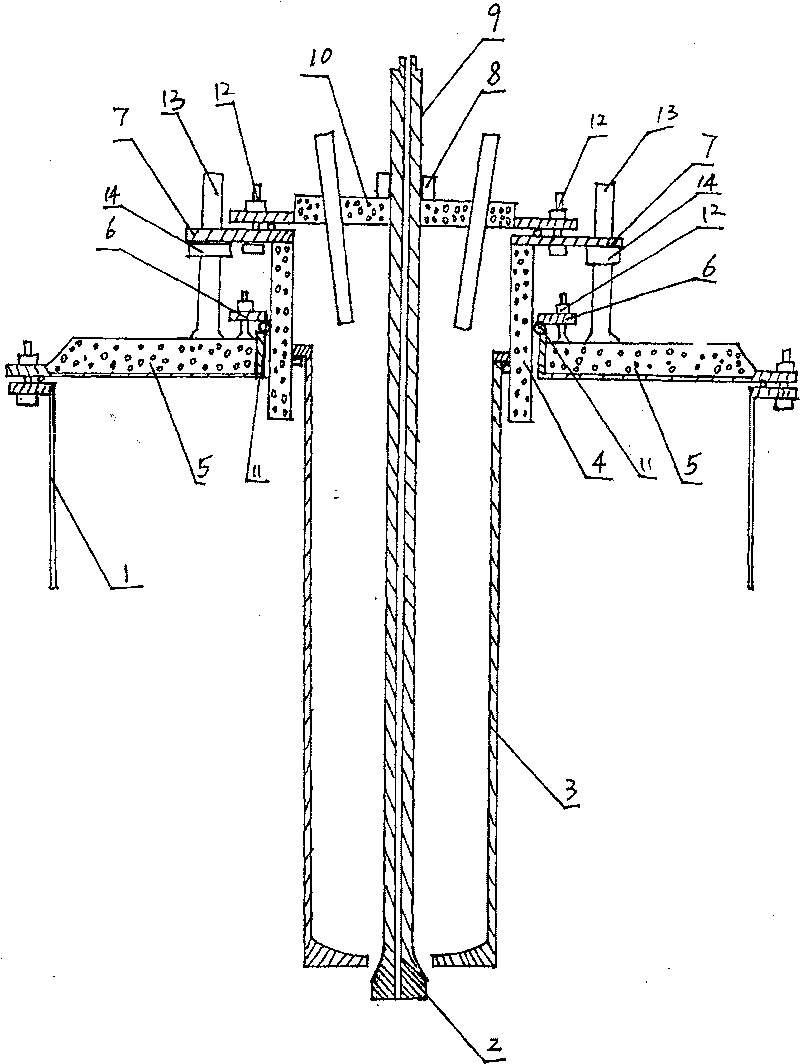

[0018] Example 1. refer to figure 1 . An energy-saving quartz continuous melting furnace, comprising a furnace body 1, a furnace cover and a core rod 9, the bottom of the core rod 9 is provided with a former 2, and a lifting adjustment nut 8 is provided on the core rod 9 connected to the furnace cover; the furnace body 1 is provided with a tungsten-molybdenum crucible 3 fixedly connected to the furnace cover body 4; The lower cover 6 is an annular plate-shaped structure, the upper cover 7 is fixed on the top of the cover 4, the top cover 10 and the upper cover 7 are connected by fasteners 12, and the bottom cover 5 and the cover 4 are formed Separate arrangement, a sealing ring 11 is provided between the bottom cover 5 and the cover body 4, and the lower cover 6 is arranged on the sealing ring 11 and connected with the bottom cover 5 through fasteners 12; the bottom cover 5 is provided with an upper The adjusting bolts 13 of the loam cake 7 pass through, and the adjusting b...

Embodiment 2

[0019] Example 2. In Embodiment 1, the fastener (12) is a fastening bolt.

Embodiment 3

[0020] Example 3. In Embodiment 1, the fastener (12) is a fastening fastener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com