Micro piezoelectric motor-lens integrated driving machine

A piezoelectric motor and integrated drive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, piezoelectric devices/electrostrictive devices, etc. Failure, complex system and other problems, to achieve the effect of low cost, high driving force and efficiency, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings non-restrictively disclose some embodiments of the present invention, and the present invention will be further described below in conjunction with specific embodiments.

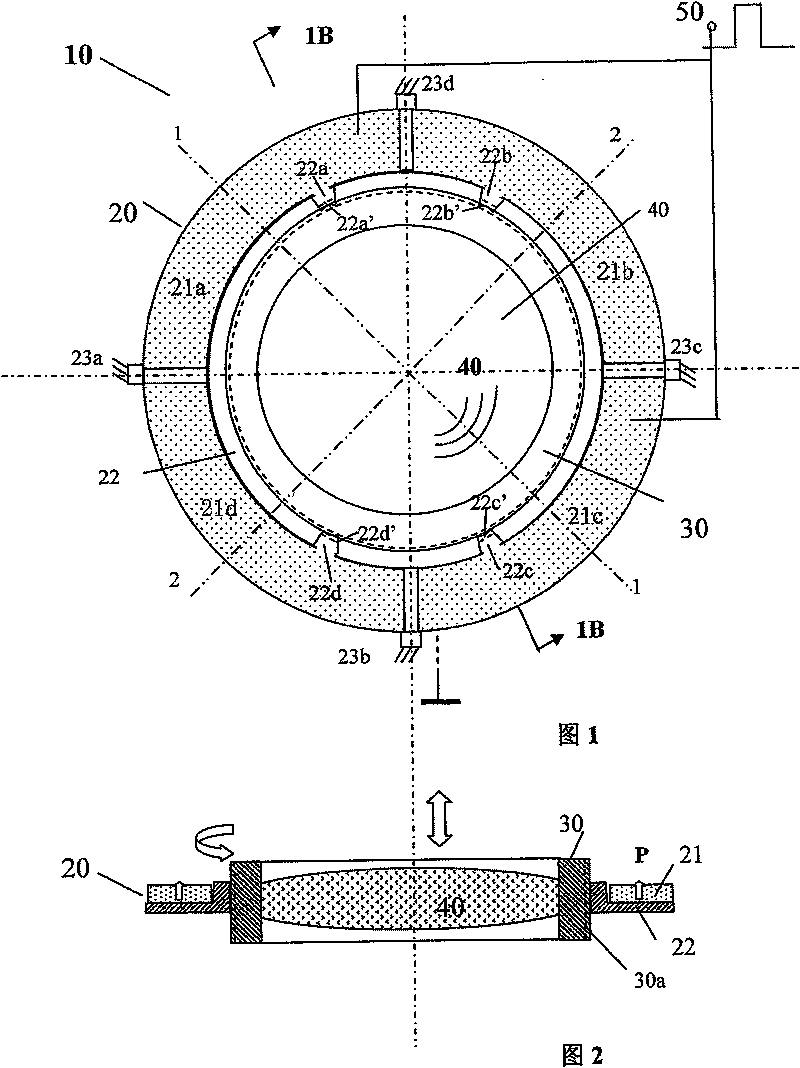

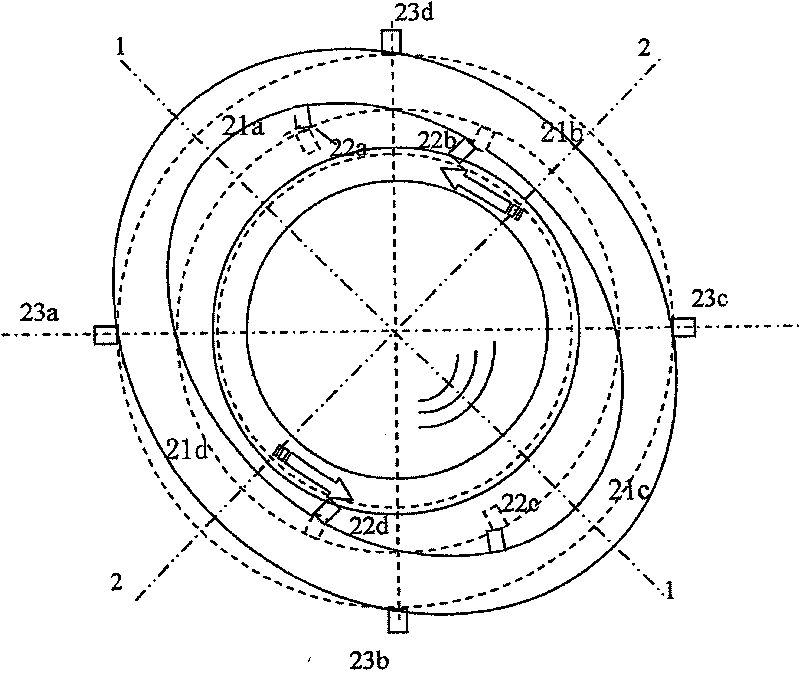

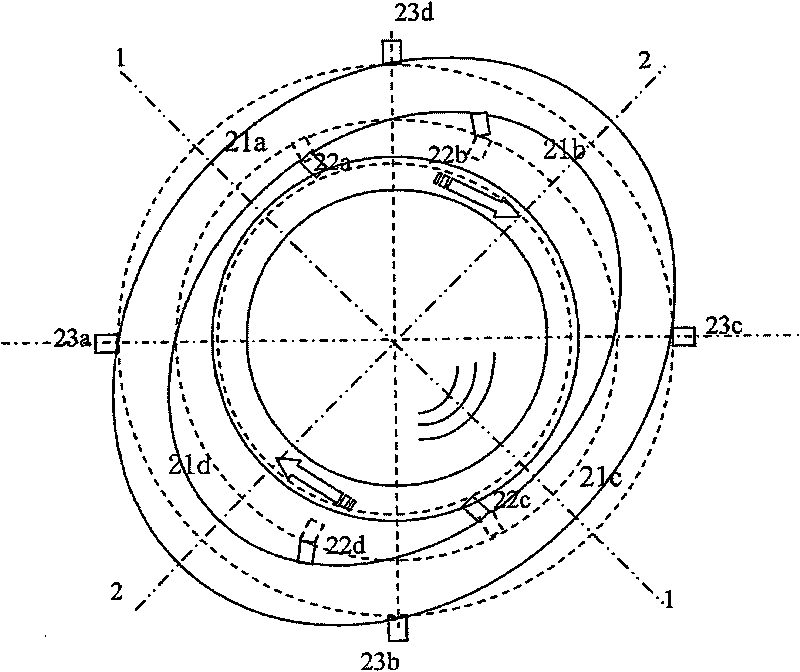

[0031] Depend on figure 1 It can be seen that the piezoelectric motor 10 shown has an annular piezoelectric stator 20, and an even number of ≥4 (four in this embodiment) centripetal antennae 22a, 22b, 22c and 22d are arranged on the inner ring of the stator. The ends have internal threads 22a', 22b', 22c' and 22d'. The motor 10 also includes a hollow cylindrical rotor 30 having external threads 30a on its exterior. The external threads of the rotor 30 coincide with the internal threads of the four antennas of the stator, so the rotor 30 can be screwed into the center of the stator 20 through threads. The driven lens element 40 is mounted directly inside the cylindrical rotor 30 . figure 2 yes figure 1 The piezoelectric motor 10 and the driven lens 40 are shown as a cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com