A self-protective lead-acid storage battery and its manufacture method

The technology of a lead-acid battery and its manufacturing method is applied in the directions of lead-acid battery, lead-acid battery construction, battery pack components, etc., which can solve the problems of lead-acid battery damage, damage, gas evolution, etc., so as to improve the service life, Simple structure, prolong normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

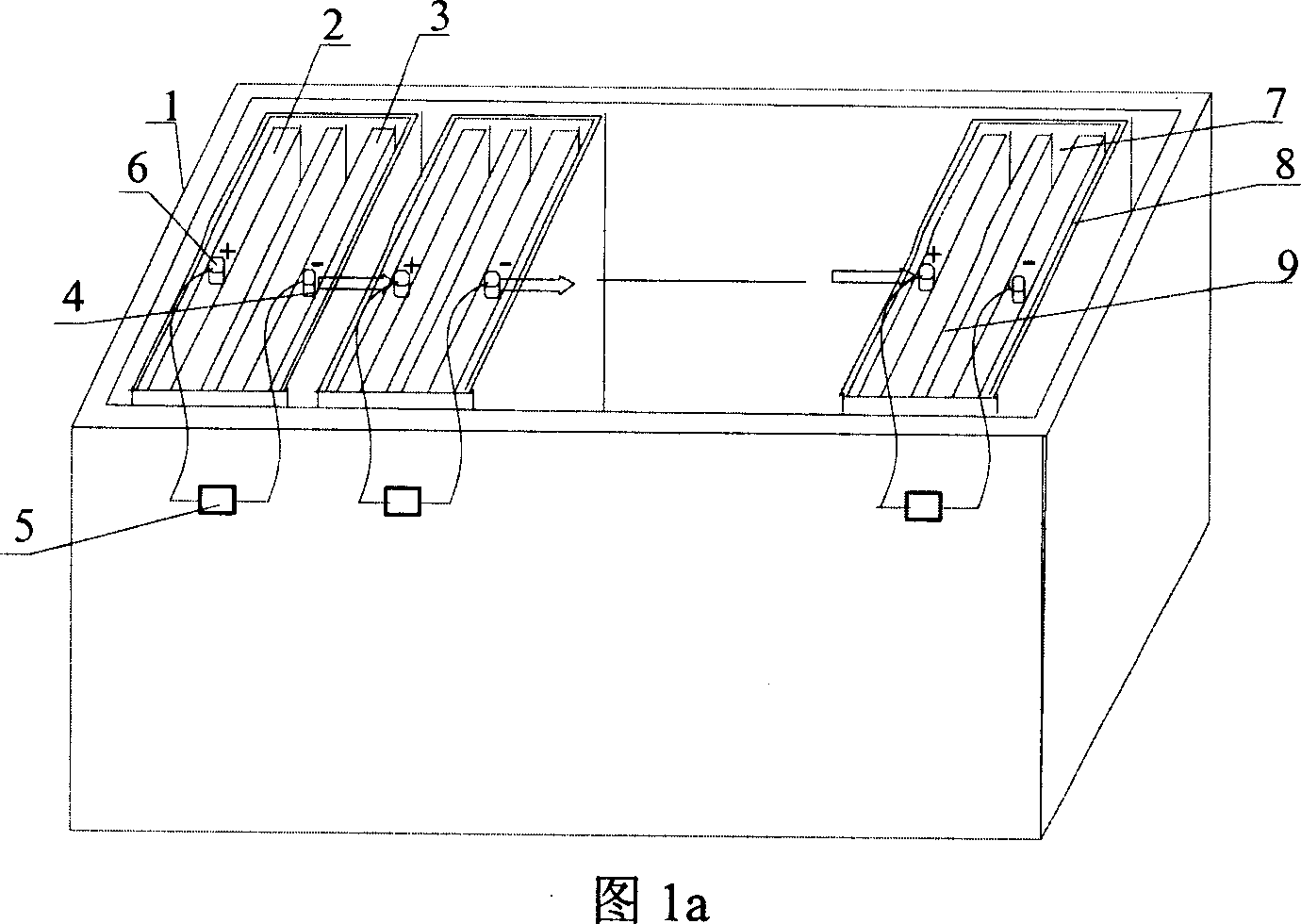

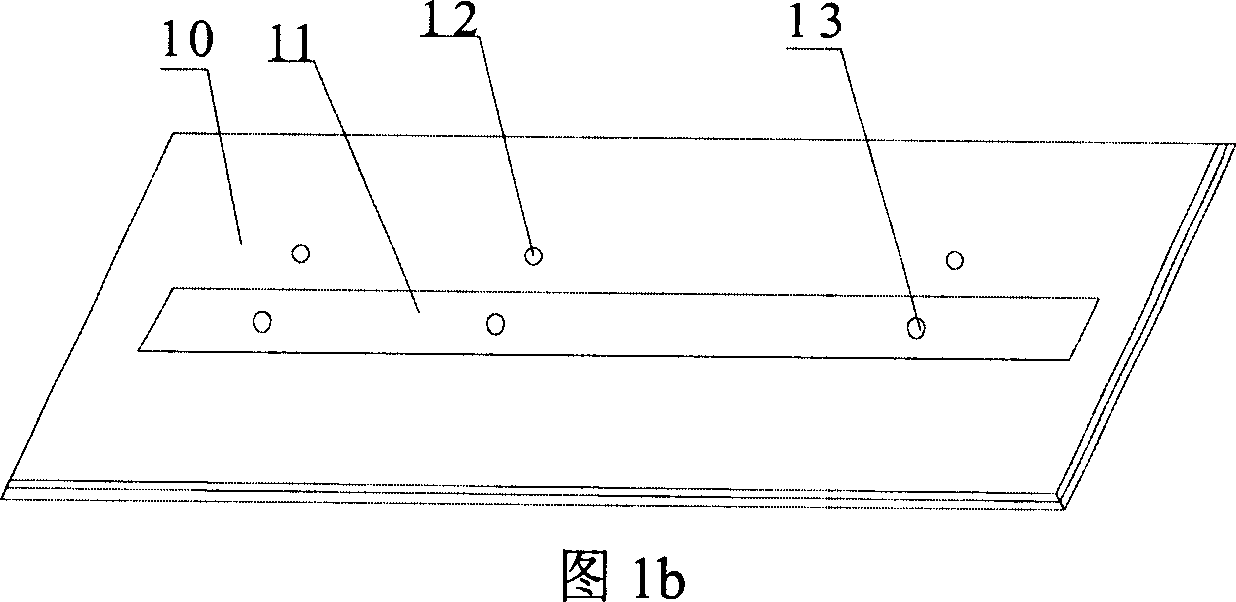

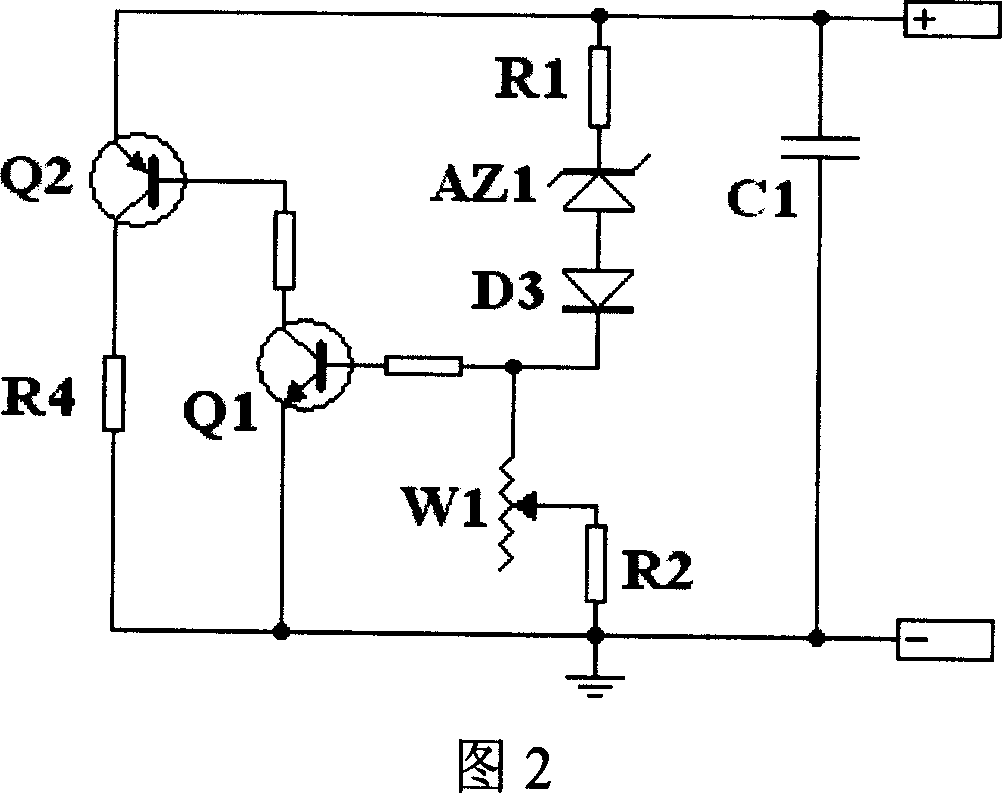

[0027] As shown in Fig. 1a and Fig. 2, a kind of self-protection lead-acid battery, lead-acid battery comprises housing 1, is provided with a plurality of battery units 7 in housing 1, and each battery unit 7 is made of a pole for containing electrolyte The plate groove 8, the positive grid 2, the separator 9 and the negative grid 3 are composed. There is a positive terminal 6 on the positive grid 2, a negative terminal 4 on the negative grid 3, a separator 9 is arranged between the positive grid 2 and the negative grid 3, and the positive grid in each plate groove 8 2 and the negative grid 3 form a positive and negative grid pair. The negative terminal 4 of the previous pair of positive and negative grids is electrically connected to the positive terminal 6 of the next pair of positive and negative grids, and connected in sequence to form a lead-acid battery in series. A bypass circuit 5 for shunting the positive and negative grid pairs (2, 3) when charging is connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com