Combined suspension moving hydraulic support with universal upper bracket and lower hanging beam

A technology of hydraulic support and hydraulic support, applied in support/support, mining equipment, earthwork drilling, etc., can solve the problems of high manufacturing cost, single function, poor integrity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

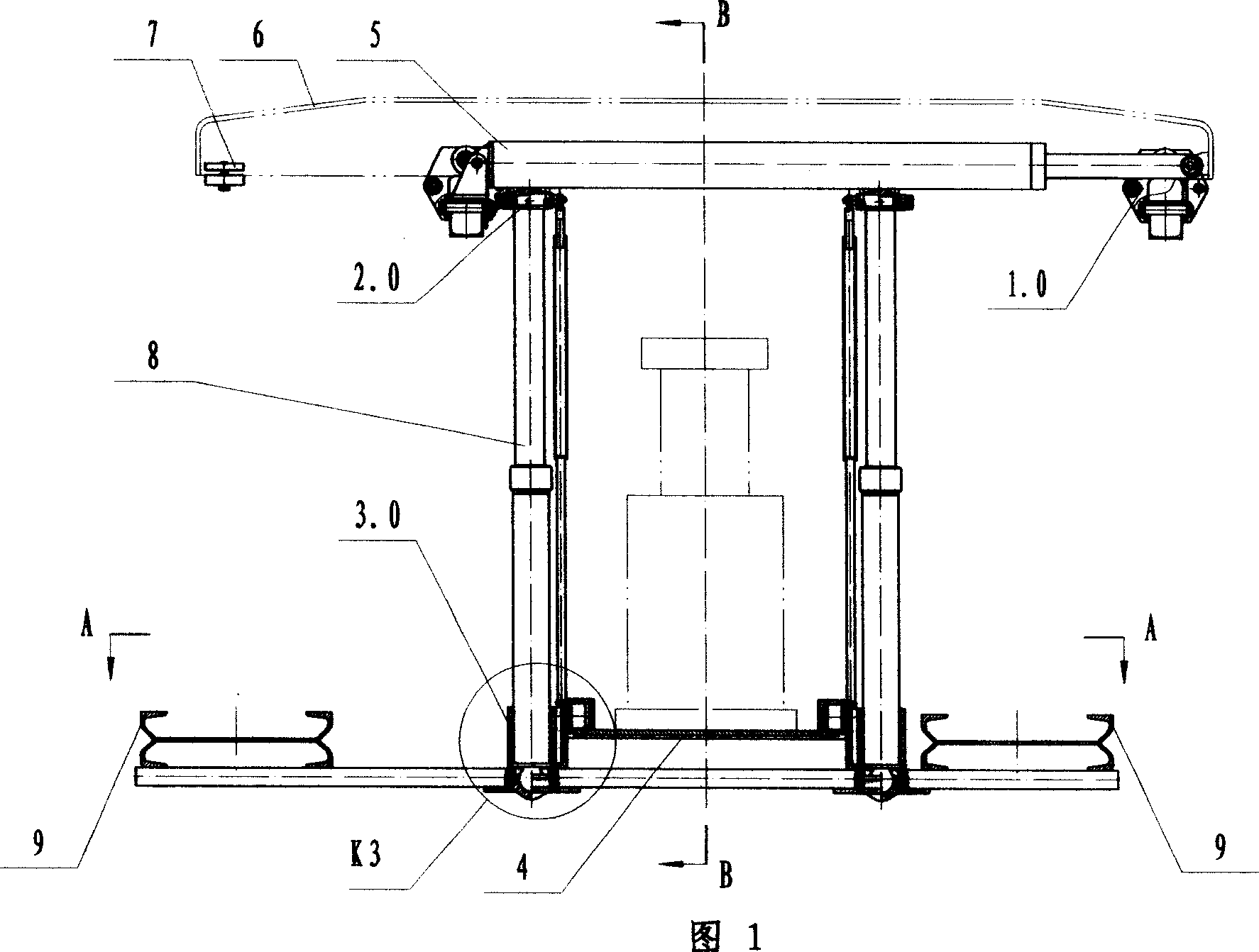

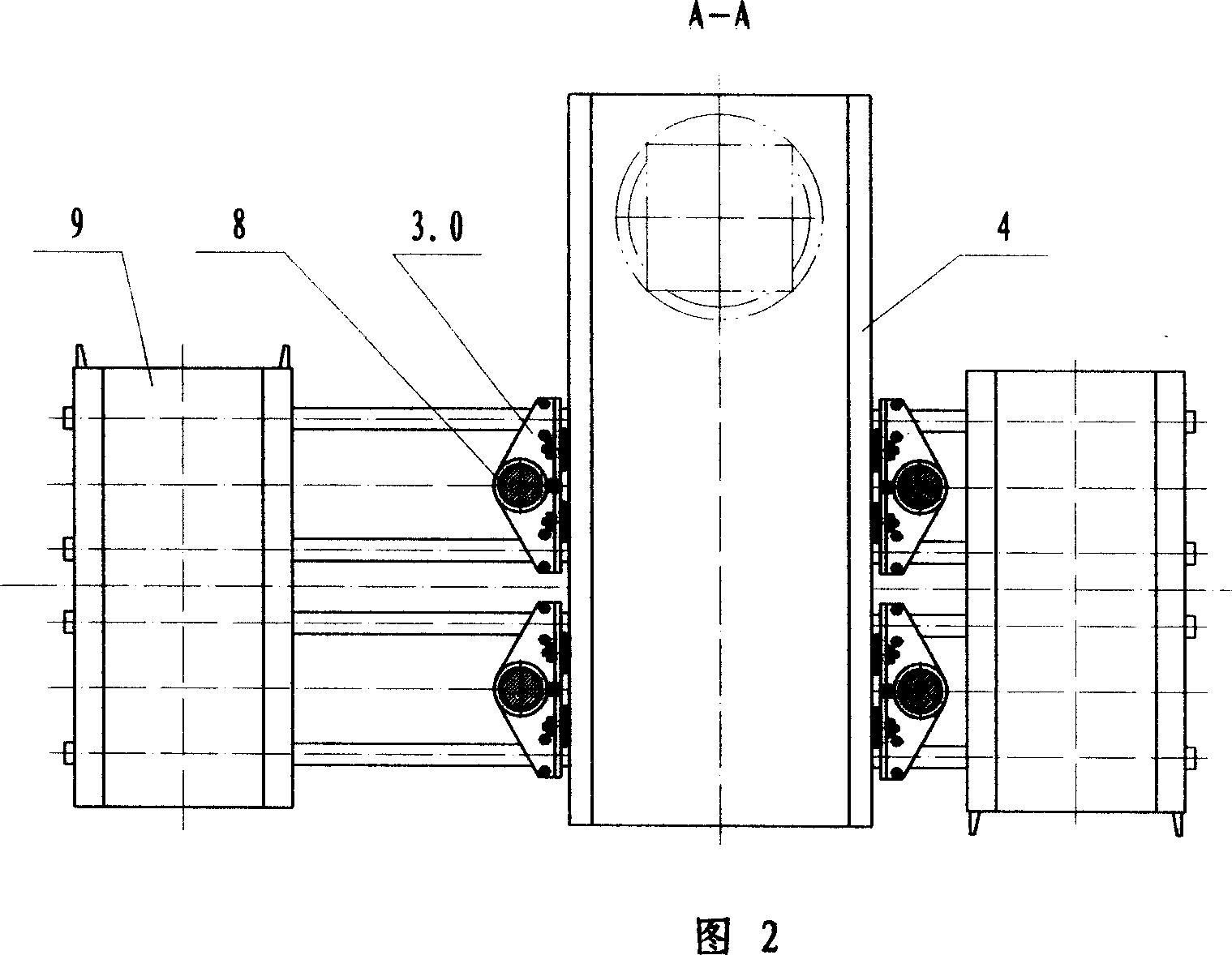

[0040] 1. The universal bracket (1.0) is composed of a roller frame and a bracket.

[0041] Roller frame is assembled into by hanging wheel (1.1), supporting wheel (1.2), and connecting support (1.3) with axle, bearing, see Fig. 6, Fig. 7.

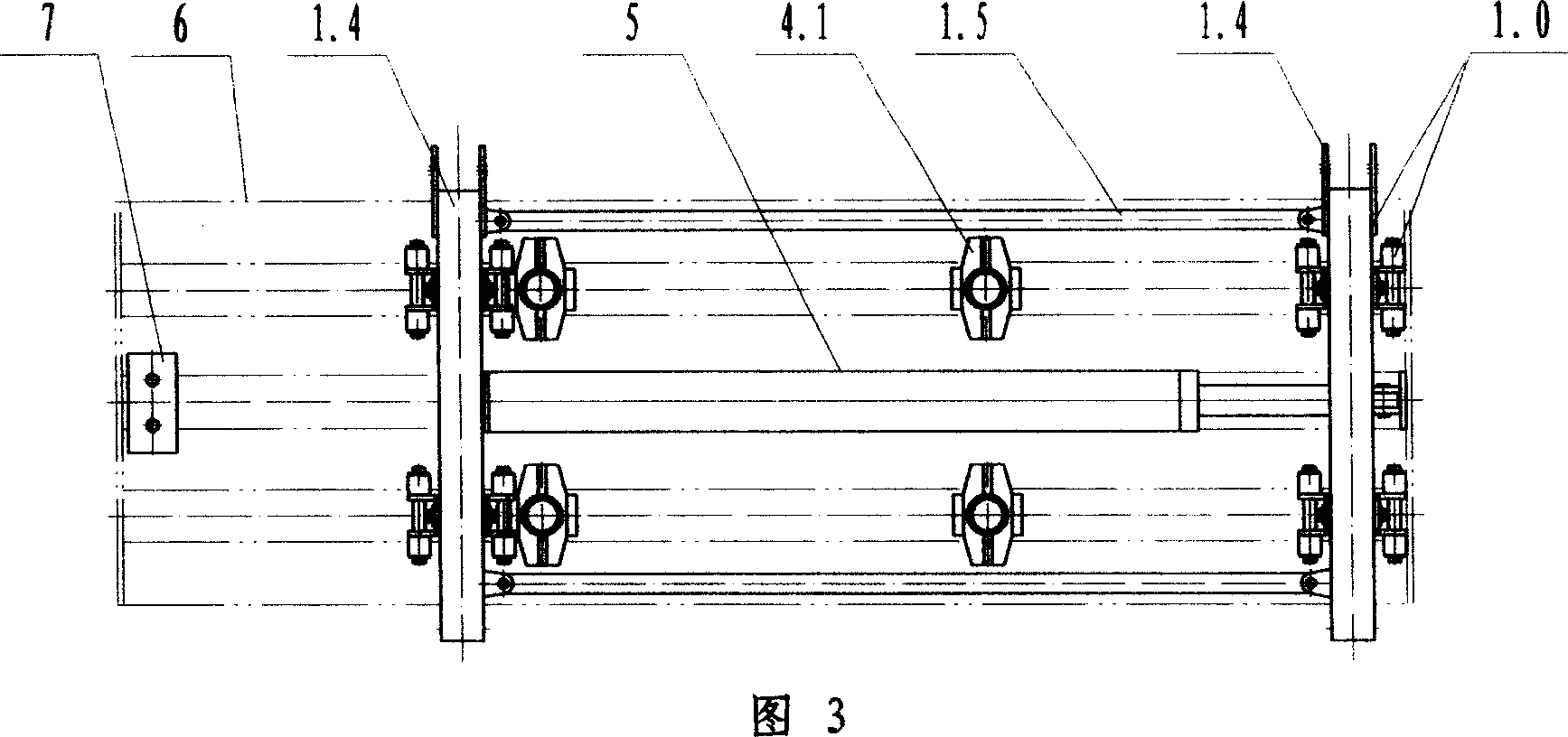

[0042] The bracket is composed of two or more non-parallel longitudinal beams (1.4) and connecting rods (1.5) hinged with pins. Longitudinal beams (1.4) with different lengths respectively form brackets with different lengths, and the two longitudinal beams (1.4) can move up and down and rotate mutually, as shown in Fig. 3, Fig. 5 and Fig. 15 .

[0043] Connecting support (1.3) is connected with longitudinal beam (1.4) with pin shaft slotted hole, see Fig. 6, Fig. 7.

[0044] Top beam (6) is contained between suspension wheel (1.1) and supporting wheel (1.2), see Fig. 5, Fig. 6.

[0045] Therefore, the roller frame and the bracket can move up and down and rotate each other, the top beam (6) can realize rolling displacement between the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com