Seamless steel tube evaporator

A technology of seamless steel pipe and evaporator, which is applied in the direction of evaporator/condenser, heat exchanger sealing device, application, etc., can solve the problems of long production cycle, inconvenient installation and operation, and easy water leakage, and reduce manufacturing and processing costs Processing, refrigeration sealing effect is good, the effect of high electric output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

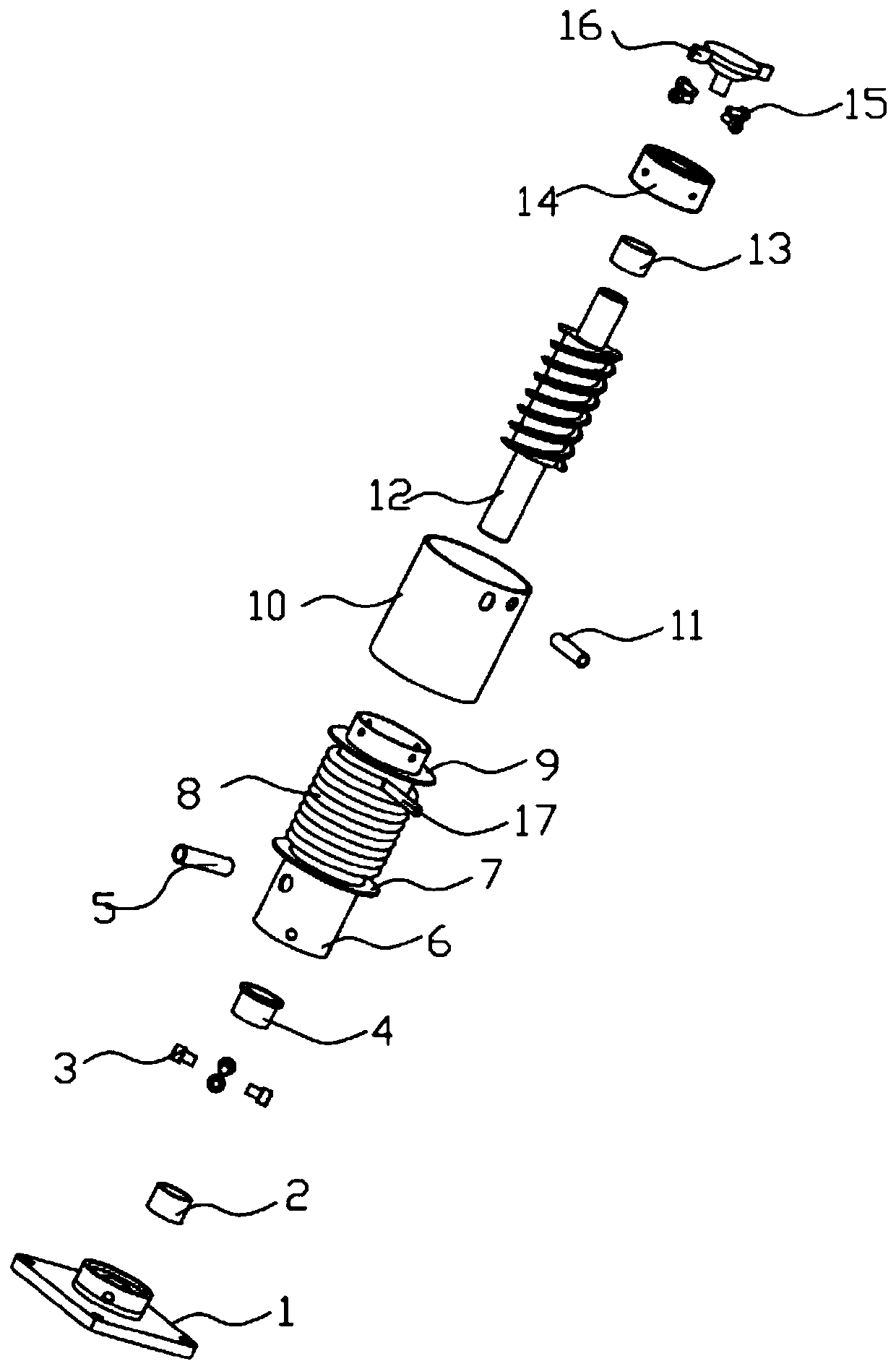

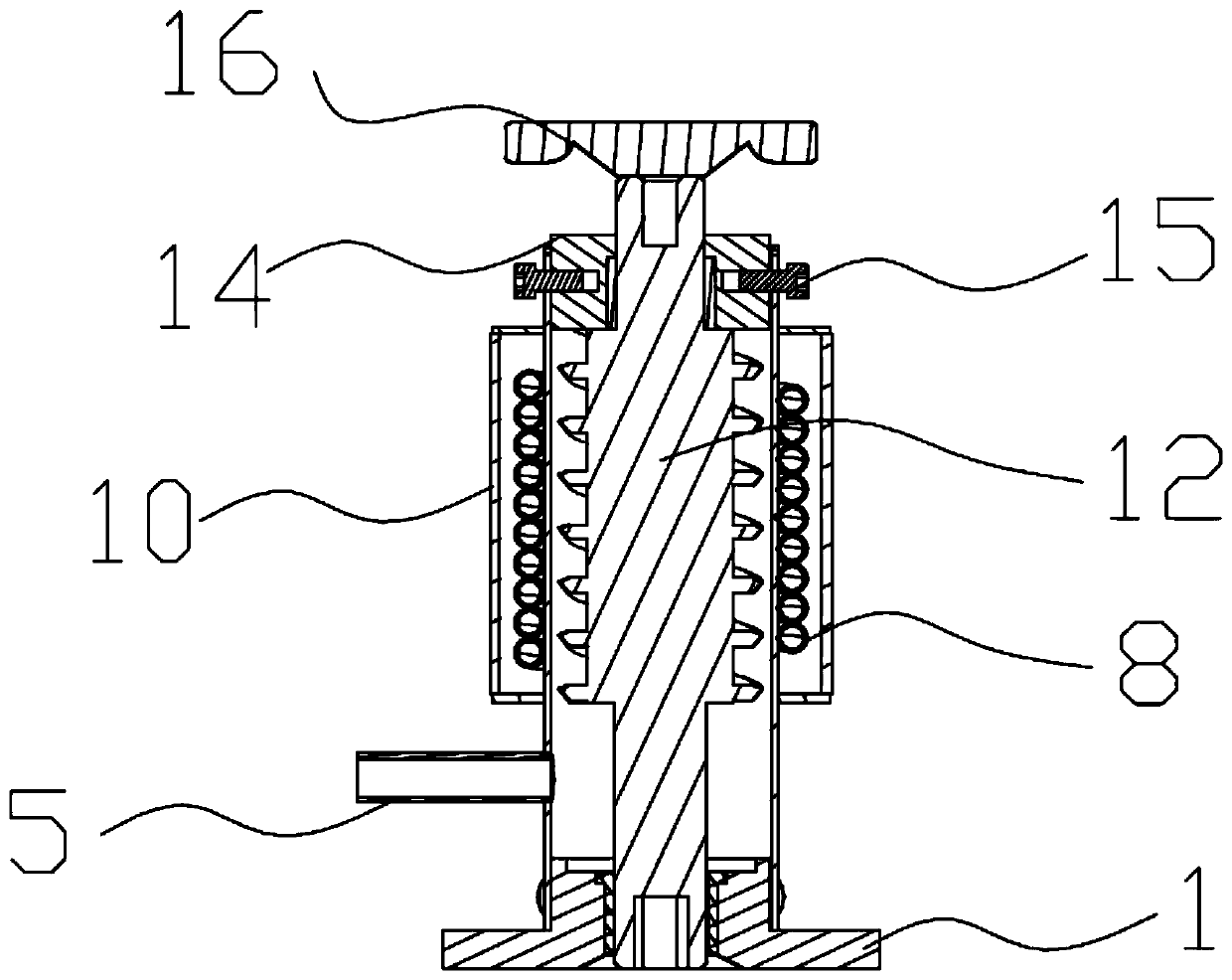

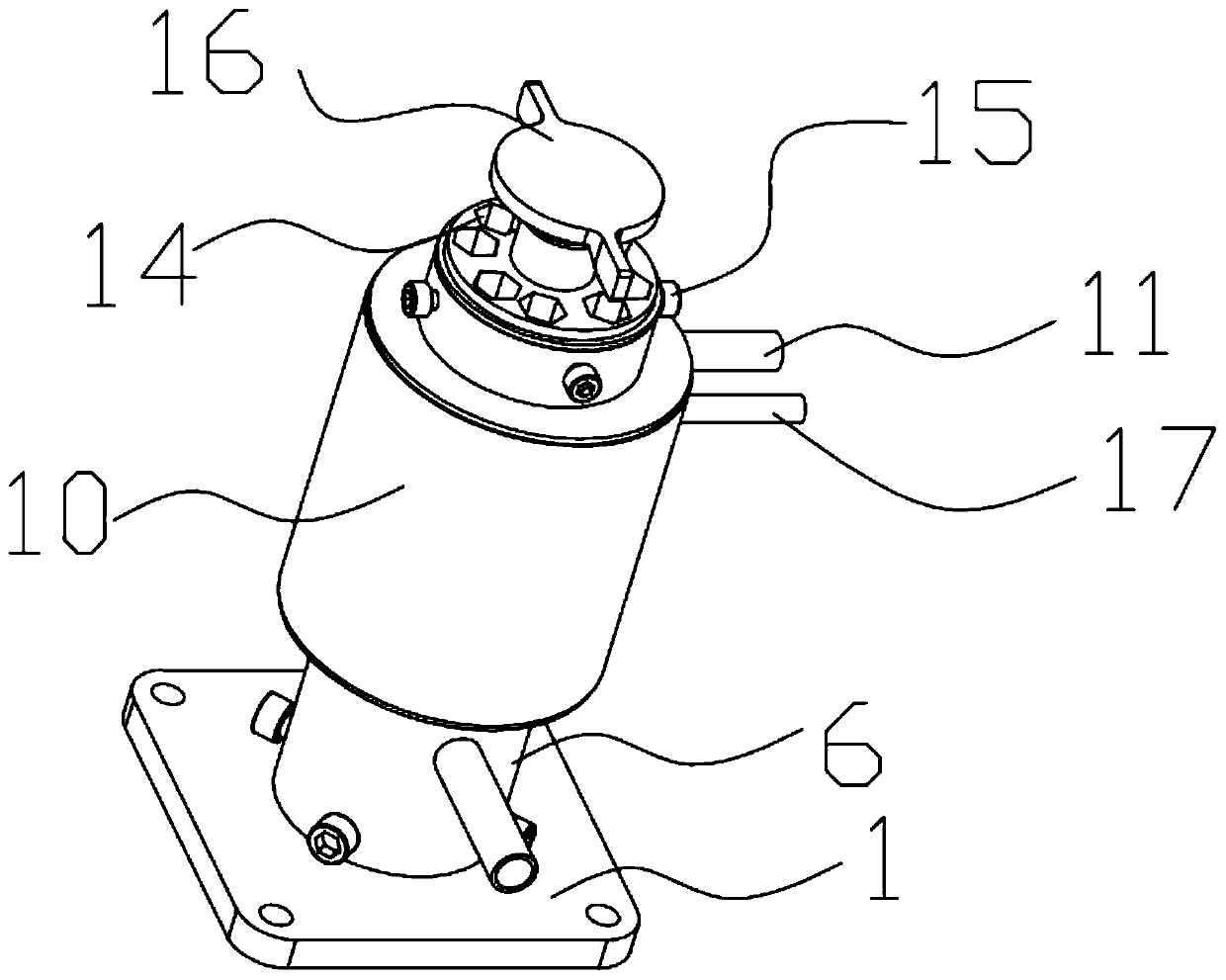

[0033] see Figure 1 to Figure 3 As shown, a seamless steel pipe evaporator includes an evaporator, an evaporator main tube 6 and a cooling copper tube. The evaporator main tube 6 and the cooling copper tube 8 are installed in the evaporator, and the outer circumference of the evaporator main tube 6 is closely surrounding A cooling copper tube 8 is provided, and the outside of the cooling copper tube 8 is fixedly connected to the evaporation outer sealing tube 10. The evaporator main tube 6 is a seamless steel tube, and one end of the evaporator main tube 6 is fixedly connected to the ice particle former 14. An ice blade 12 is arranged, and one end of the ice blade 12 is connected with a rotating motor, and the other end is fixedly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com