Pneumatic servo focusing mechanism

A focusing device and fine-tuning screw technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high cost, low adjustment efficiency, inconvenient operation, etc., and achieve low processing and manufacturing costs, convenient use, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

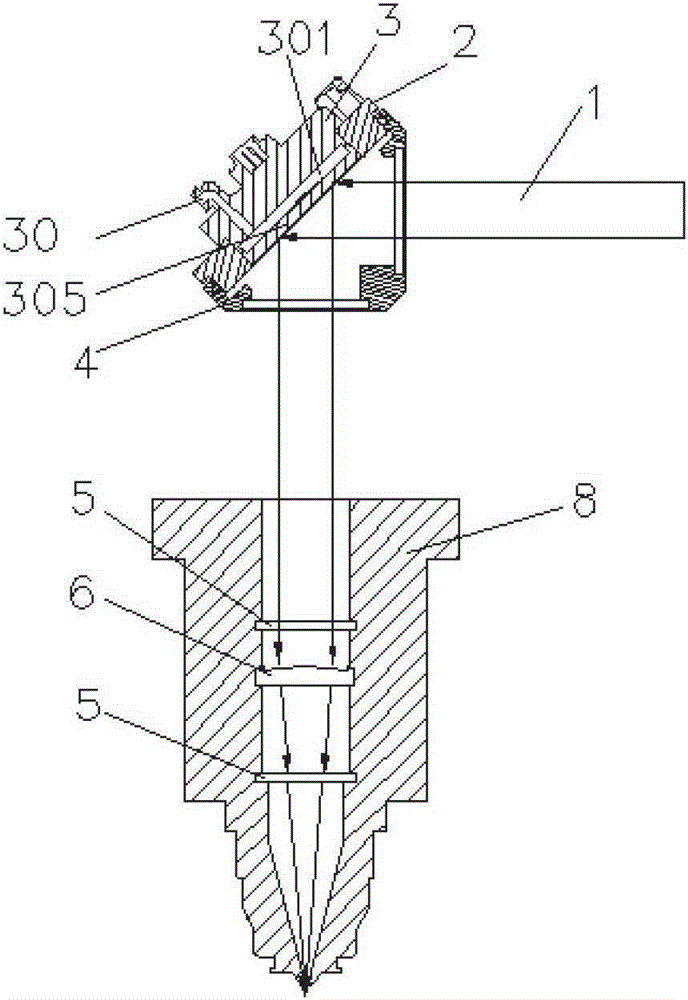

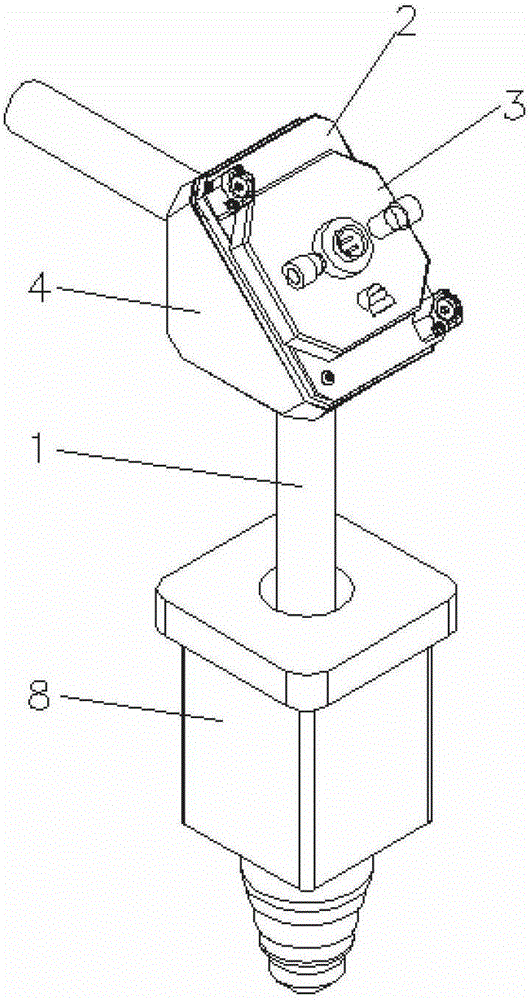

[0016] Embodiment: a pneumatic servo focusing mechanism, comprising a mounting seat 4, a mirror seat 2, a reflector 3 and a laser focusing device, the mounting seat 4 is provided with a light entry channel and a light exit channel, and the mirror seat 2 is embedded in the On the mounting seat 4, the mirror 3 is fixed on the mirror seat 2, a pressure chamber 301 is formed inside the reflector 3, the pressure chamber 301 communicates with the external air source through the pressure interface 30, and the pressure chamber 301 of the reflector 3 faces the interior of the mounting seat 4 One side wall is a lens film 305 whose curvature can be changed under pressure. The lens film 305 can reflect the light beam in the light entrance channel and then enter the beam channel of the laser focusing device through the light exit channel. The laser beam 1 passes through the reflecting mirror 3 After reflection, the lens film 305 enters the laser focusing device to focus on the focus, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com