Hinged three mold opening mechanism of glassware press

A glassware and hinged technology, which is applied in the field of hinged three-opening mechanism, can solve the problems of simple structure of glassware, difficulty in meeting aesthetic needs, and large price differences, and achieve broad market prospects, novel and beautiful shape, and high production quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

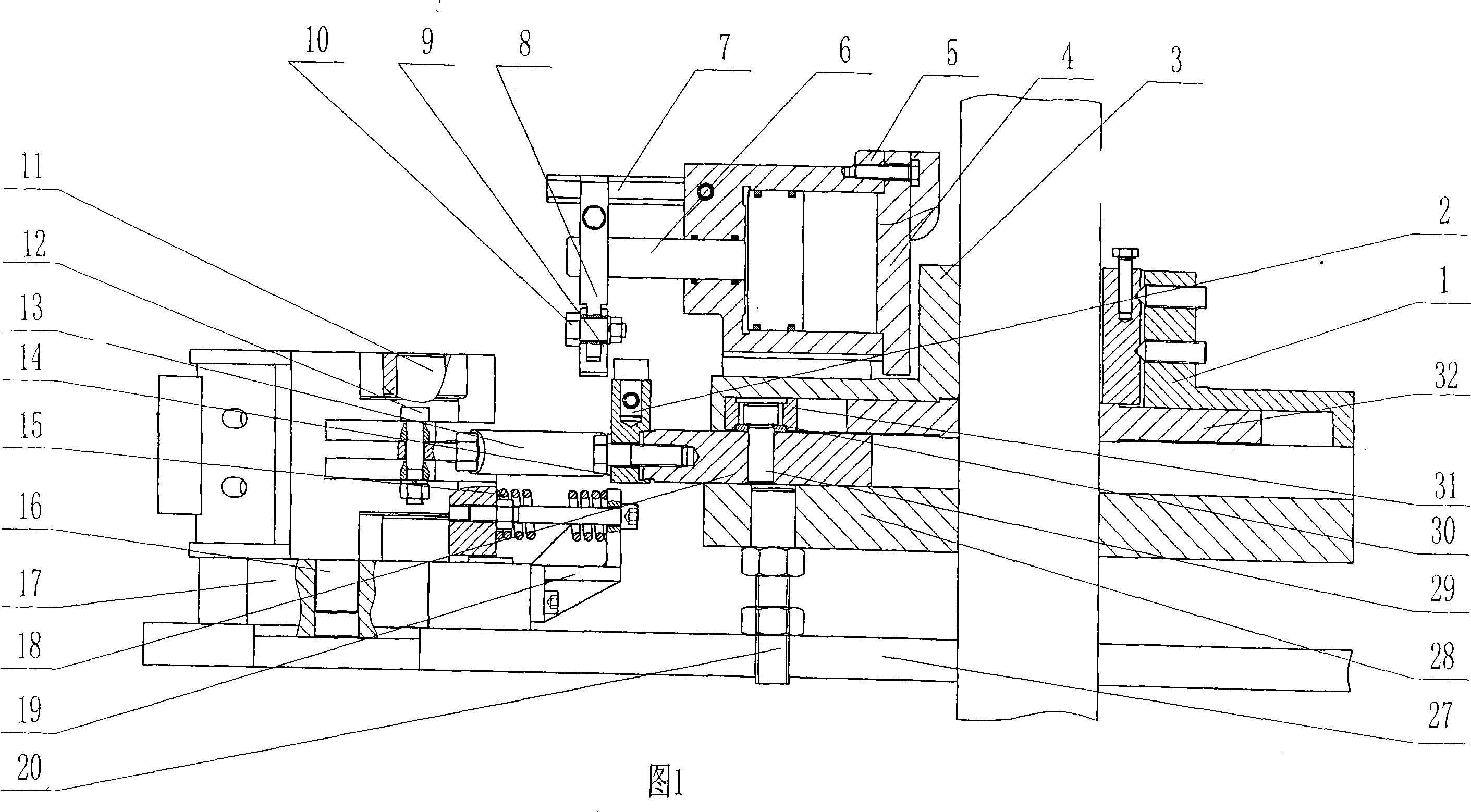

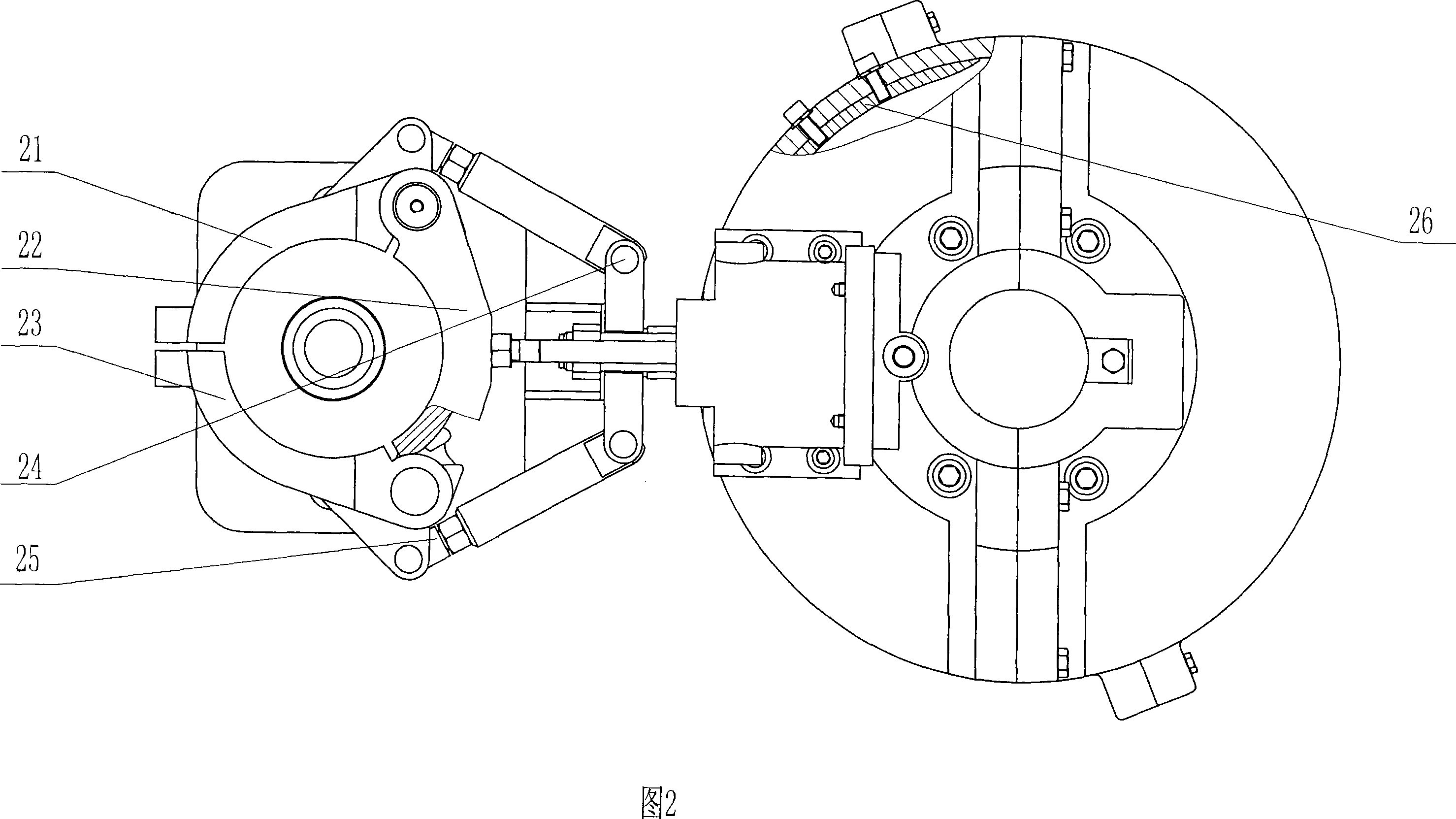

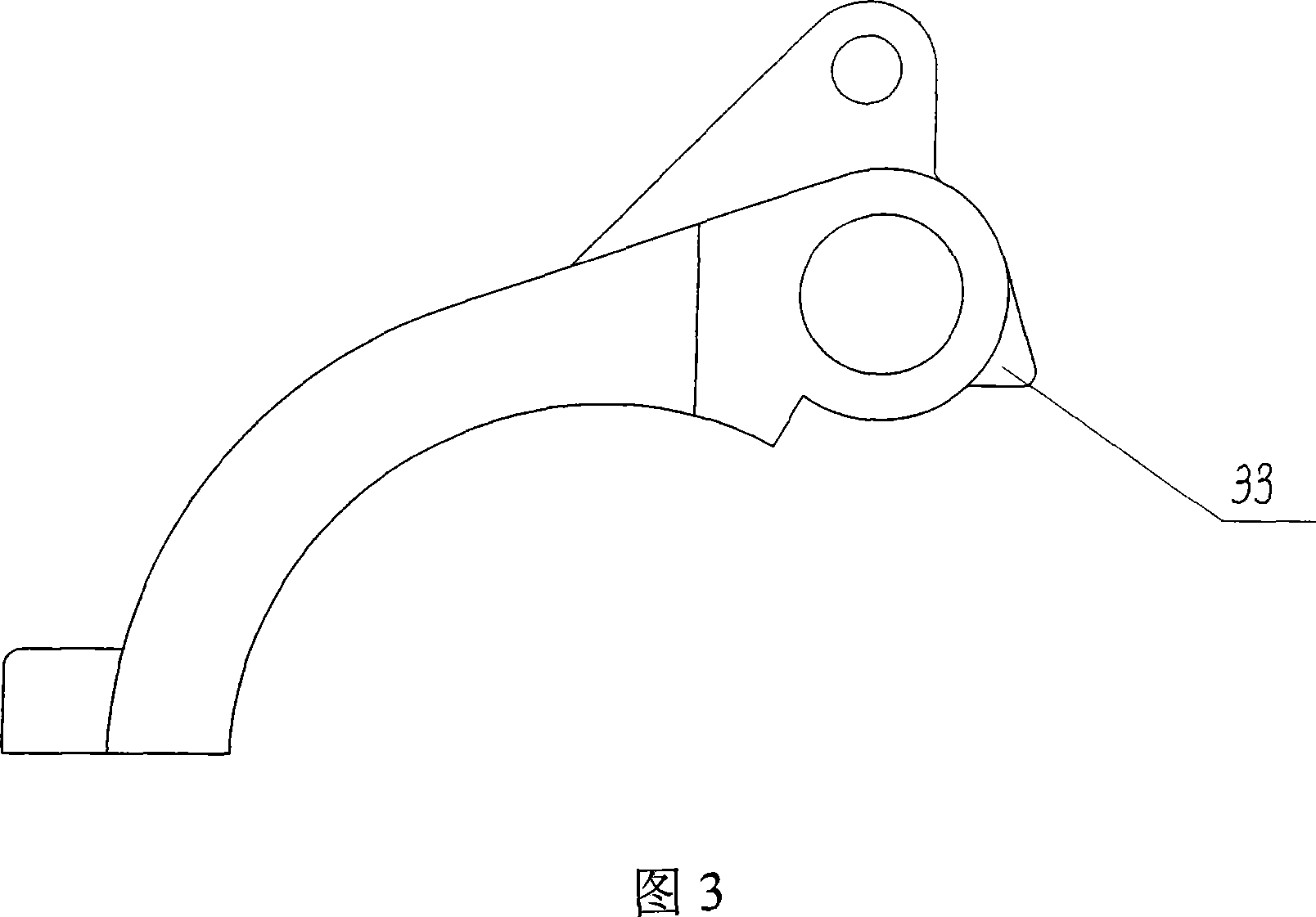

[0012] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0013] As shown in Figure 1 and Figure 2, it includes three parts: the roller assembly, the switch mold cylinder assembly and the connecting rod mold sleeve assembly, and passes through the upper right cover 1, the upper left cover 3, the bottom of the mold 16, the mold cover and the mold plate 17, and the mold opening Grooved plate pillar 20, small outer cam block 26, large plate 27, mold opening grooved plate 28, and cam 32 are connected to form; the roller assembly includes roller shaft 29, roller gasket 30 and roller 31; the switch mold cylinder assembly Including switch mold cylinder head 4, switch mold cylinder 5, switch mold cylinder piston 6, guide rod 7, switch mold lever 8, switch mold paddle 9, paddle connecting bolt 10; the guide rod 7 and switch mold cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com