Variable capacity swash plate type compressor

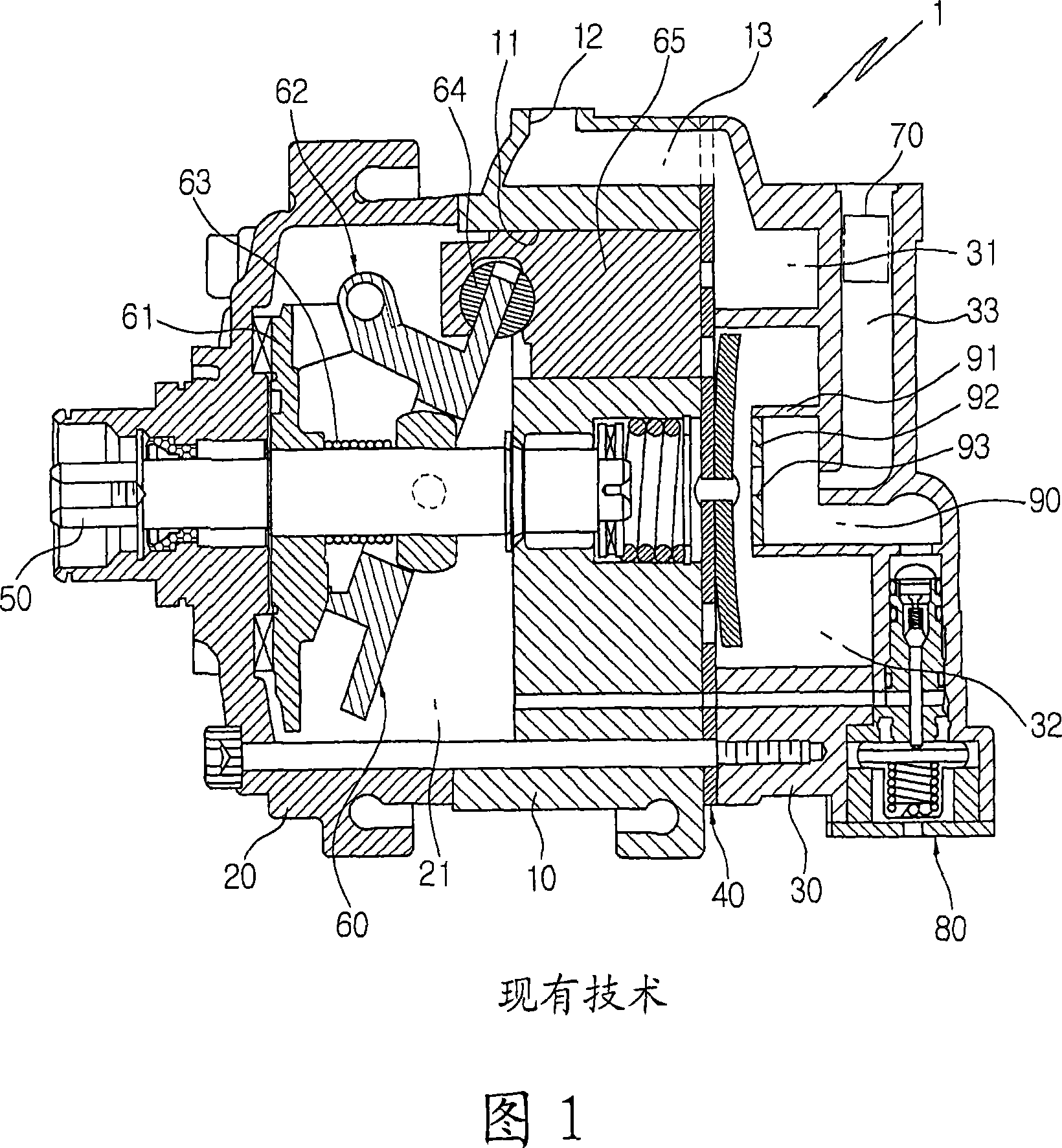

A technology of variable capacity and compressor, applied in the direction of liquid variable capacity machinery, variable capacity pump components, mechanical equipment, etc., can solve problems such as increasing the size of compressor 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

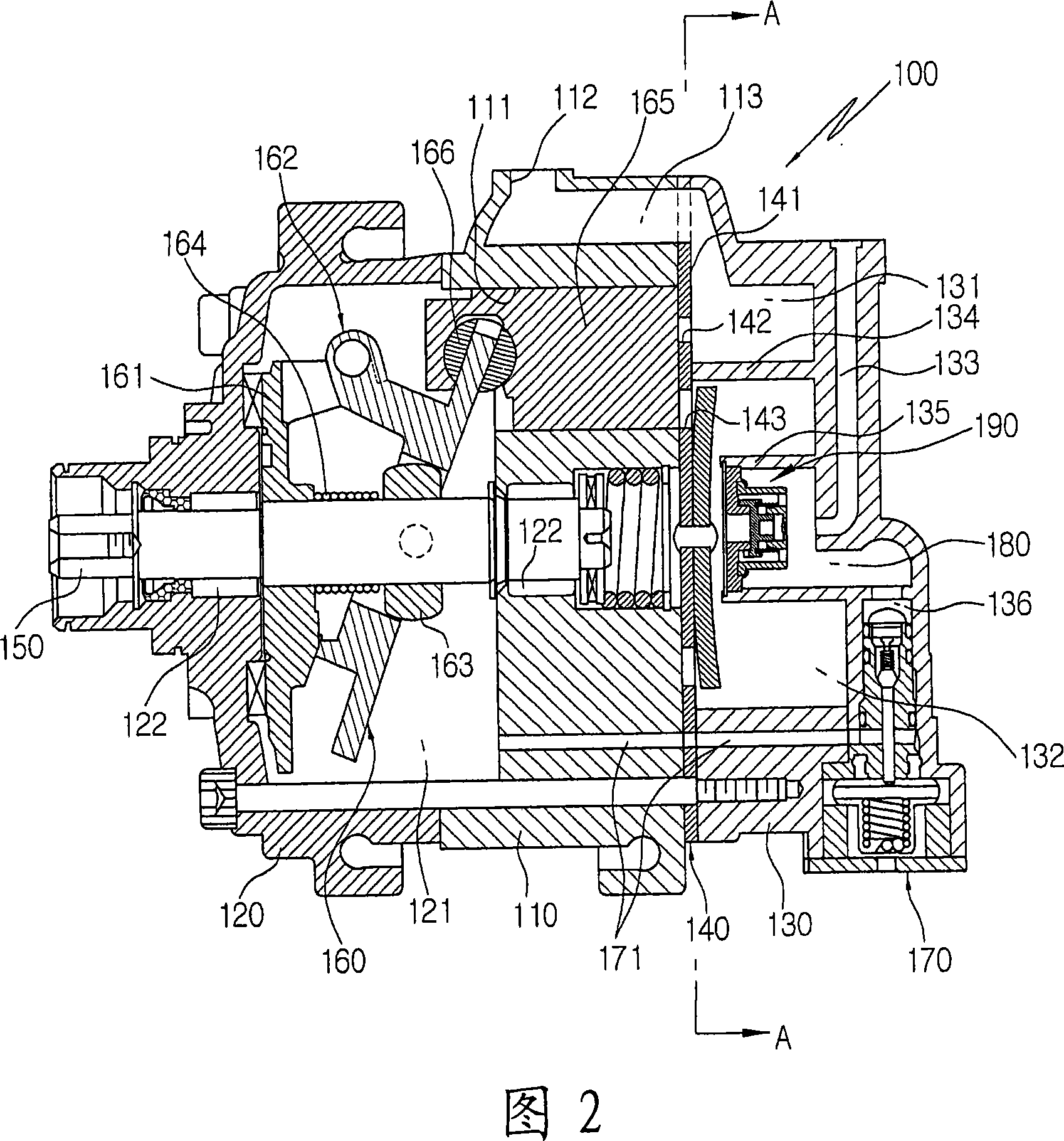

[0028] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] In the present invention, descriptions of components and operations that are the same as those of the related art will be omitted.

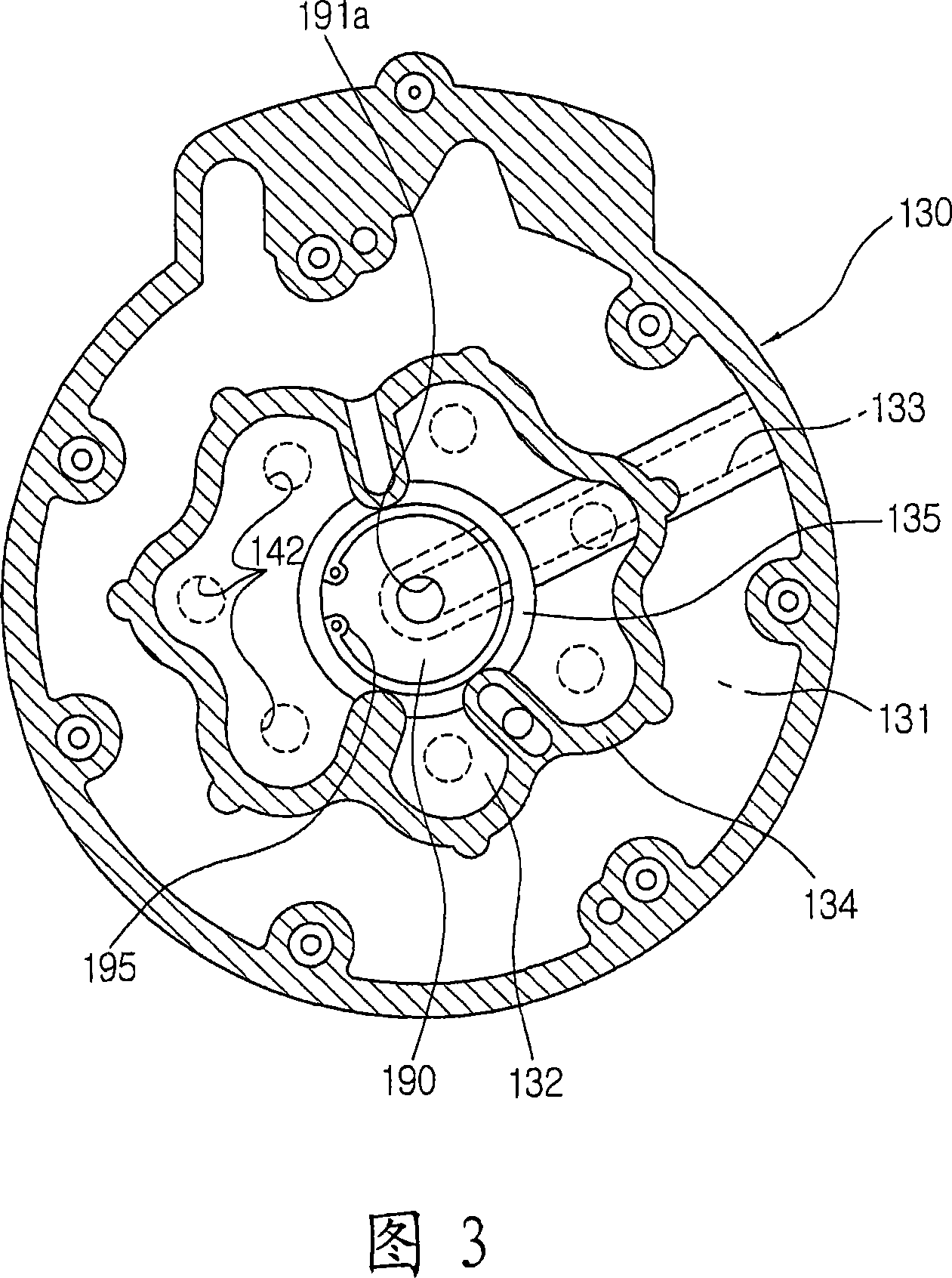

[0030] Fig. 2 is a sectional view of a swash plate type variable capacity compressor according to the present invention, Fig. 3 is a sectional view taken along line A-A of Fig. 2 , Fig. 4 is a partially enlarged sectional view of a discharge muffler chamber of a slant plate type variable capacity compressor, And Fig. 5 is a sectional view of the check valve of the swash plate type variable capacity compressor.

[0031] As shown in the figure, the swash plate type variable displacement compressor 100 according to the present invention includes: a cylinder block 110 having a plurality of cylinder holes 111 formed therein; a front cover 120 joined to the front of the cylinder block 110 and having a sealed cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com