Melting-point-changeable lead-free composite soldering material, soldering paste, thire preparation and use

A hybrid welding and melting point technology, applied in the direction of mixing methods, chemical instruments and methods, welding equipment, etc., can solve the problems of increasing the difficulty of welding process, reducing bridging short circuit, and large melting point gap, etc., to reduce the peak wetting time , reduce high temperature side effects, and strong anti-collapse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation of 40(SnZn9)-60(SnAg4.0Cu0.5) solder paste:

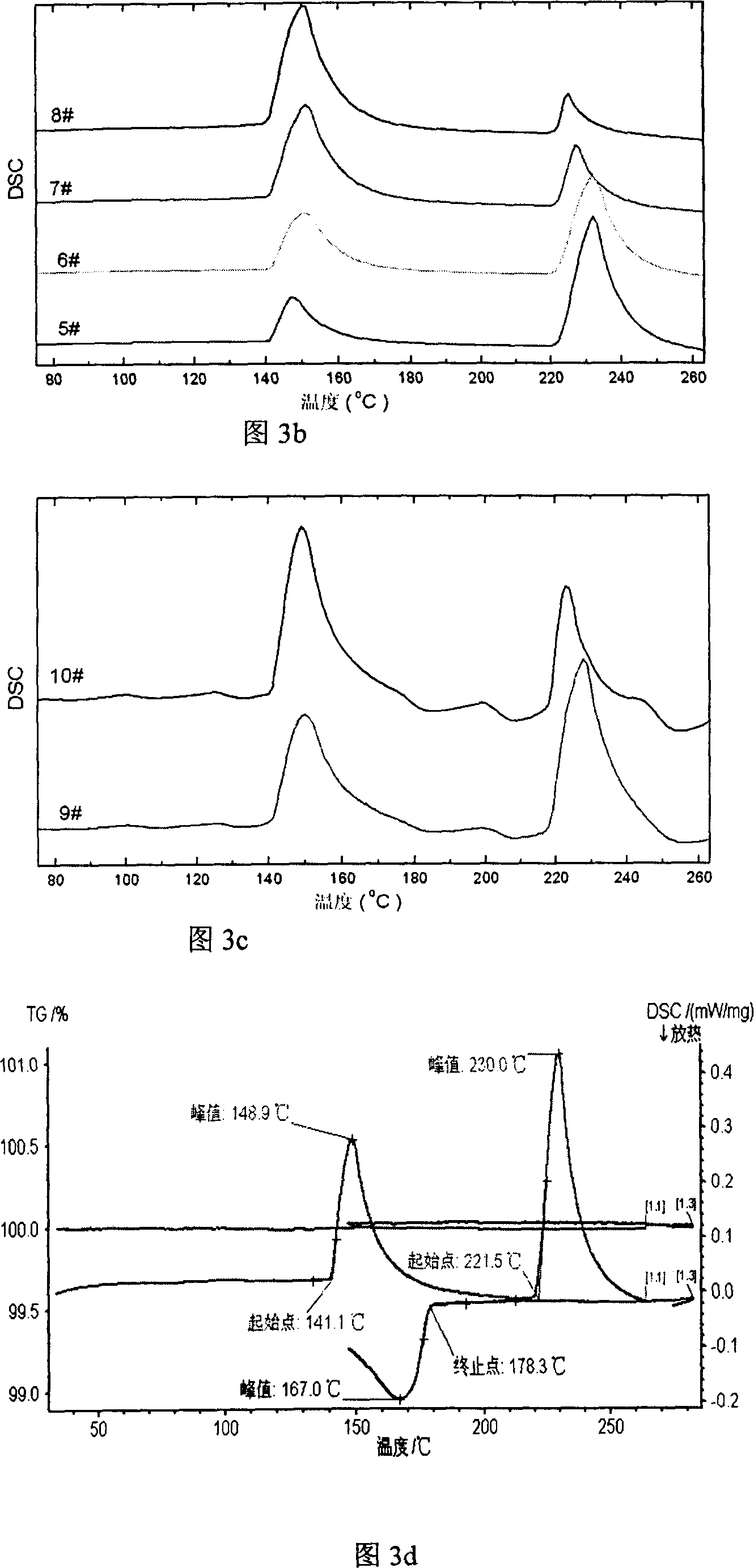

[0041] Weigh 10g of 2.3# (38-63μm) solder powder of SnZn9 (melting point 199℃), weigh 15g of 3# (25-45μm) solder powder of SnAg4.0Cu0.5 (melting point 217℃), and put it into the planetary ball mill tank Mix thoroughly for 20 minutes, and then add 12% by weight universal flux (Cr22LU synthetic rosin flux from Aifa Company) according to the proportion. Stir and mix under a certain temperature (room temperature) under nitrogen protection, and pour it into the solder paste box. Store in the refrigerator for later use.

Embodiment 2

[0042] Example 2 Preparation of 95(SnAg3.5)-5(CuP8.3) solder paste:

[0043] Weigh 23.75g of 3# (25-45μm) solder powder with SnAg3.5 (melting point: 221℃), and weigh 1.25g of CuP8.3 (melting point: 714℃) fine powder (-25μm), and put it into the planetary ball mill tank. Mix for 20 minutes, and then add 12% by weight universal flux (Cr22LU synthetic rosin flux from Aifa Company) in proportion, stir and mix under certain temperature conditions (in the cold storage at 0℃), and pour it into the solder paste box. Store in the refrigerator for later use.

Embodiment 3

[0044] Example 3 Preparation of 80(SnAg4.0Cu0.5)-20(CuP8.3) solder paste:

[0045] Weigh 20g of 3# (25-45μm) solder powder of SnAg4.0Cu0.5, weigh 5g of CuP8.3 fine powder (-25μm), put it into a planetary ball mill tank and mix well for 20min, then add 12% by weight in proportion General-purpose soldering flux (Cr22LU synthetic rosin-based soldering flux from Believe Airfa Company), stir and mix at a certain temperature (room temperature), pour it into the solder paste box, and store it in the refrigerator for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com