In-situ alloying type lead-free solder and preparation method thereof

A lead-free solder and alloying technology, applied in the direction of mixing methods, chemical instruments and methods, welding equipment, etc., can solve the problems of reducing the width of the welding process window, poor resistance to thermal cycles of the melting point, and increasing the difficulty of welding, etc., to achieve saving Inventory costs, increased production flexibility, and the effect of extended wetting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

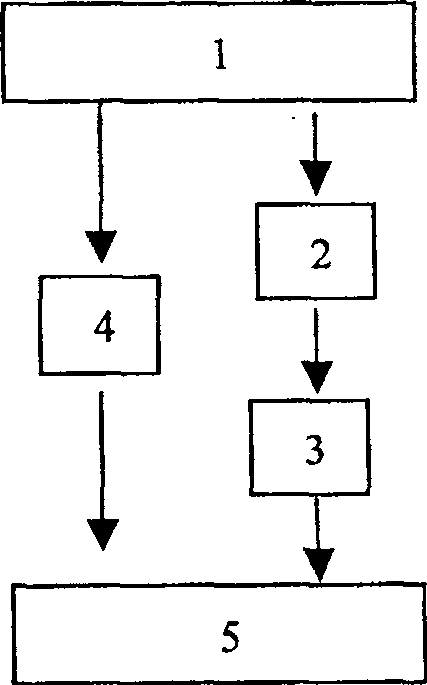

Method used

Image

Examples

Embodiment 1

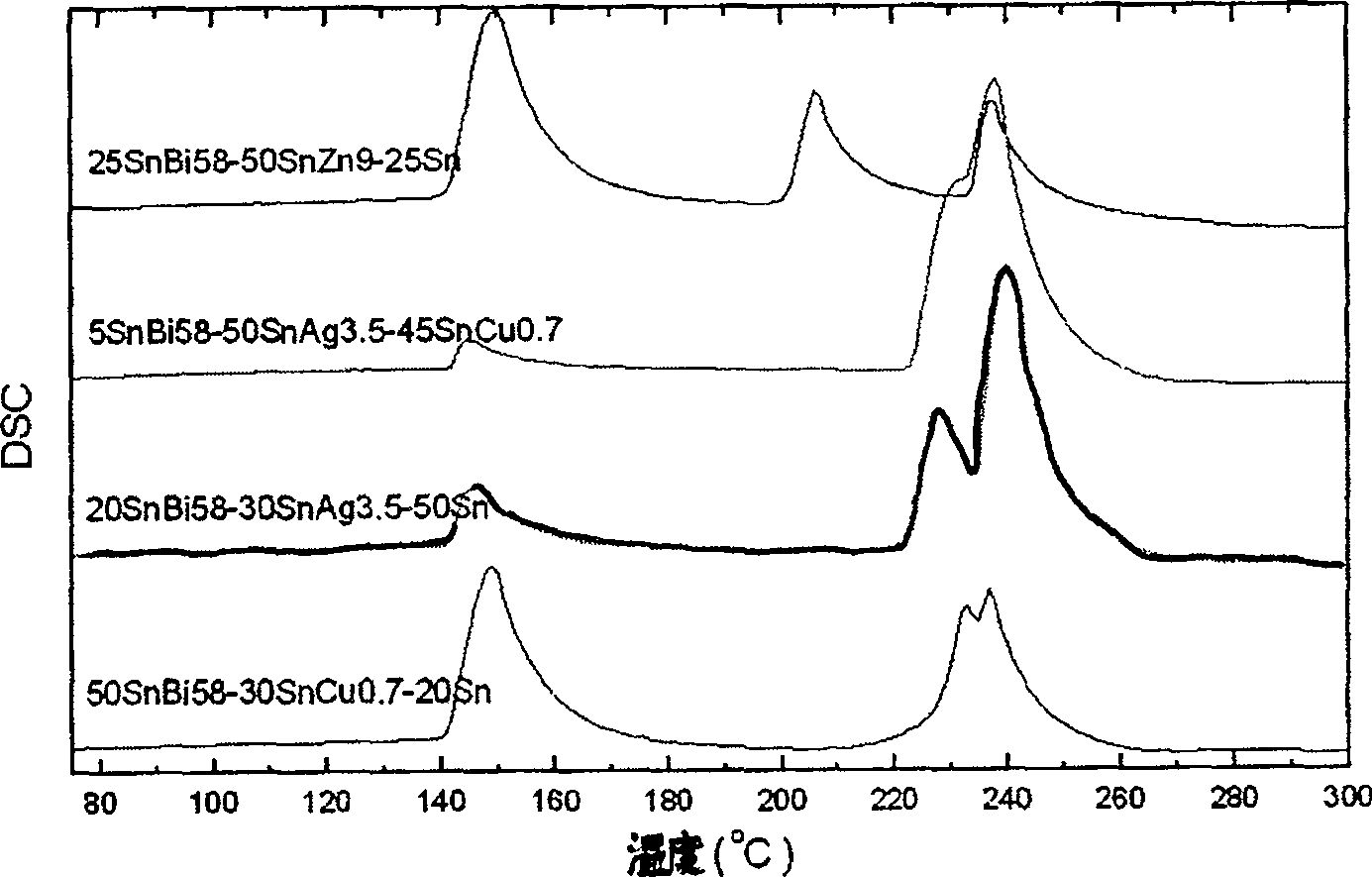

[0028] Example 1 Preparation of 50(SnBi58)-30(SnCu0.7)-20Sn solder powder:

[0029] Use centrifugal atomization or ultrasonic atomization or gas atomization technology to prepare in-situ alloying type lead-free solder monomer powder - SnBi58 (melting point 139 ℃) alloy solder powder, SnCu0.7 (melting point 227 ℃) alloy solder powder and single substance Pure Sn (melting point 231°C) powder. Use a nitrogen-protected vibrating sieve to classify, then weigh 12.5g of 3# (25-45μm) solder powder of SnBi58, 7.5g of 3# (25-45μm) solder powder of SnCu0.7, and weigh 3# of pure Sn (25-45μm) 5g of solder powder, put it into a planetary ball mill tank under the condition of room temperature and filled with argon, mix it well for 20min, and store it for later use.

Embodiment 2

[0030] Example 2 Preparation of 10(SnBi58)-80(SnCu0.7)-10Sn solder powder:

[0031] Powder making and grading methods are the same as in Example 1, then weigh 2.5g of 2.3# (38-63μm) solder powder of SnBi58, weigh 20g of 4# (20-38μm) solder powder of SnCu0.7, and weigh 3# of pure Sn #(25~45μm) Solder powder 2.5g, put it into a planetary ball mill tank under the condition of argon filling at room temperature and mix it well for 20min, and store it for later use.

Embodiment 3

[0032] Embodiment 3 Preparation of 17(SnBi58)-71(SnCu0.7)-12Sn solder powder:

[0033]Powder making and grading methods are the same as in Example 1, then weigh 17g of 3# (25-45μm) solder powder of SnBi58, weigh 71g of 3# (25-45μm) solder powder of SnCu0.7, and weigh 3# of pure Sn (25-45μm) solder powder 12g, put it into a planetary ball mill tank in a zero-degree cold storage and mix it well for 20 minutes, and store it for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com