Rain grating without up-spurting air

A rain grate and gas channeling technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as environmental disharmony and odor of underground pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

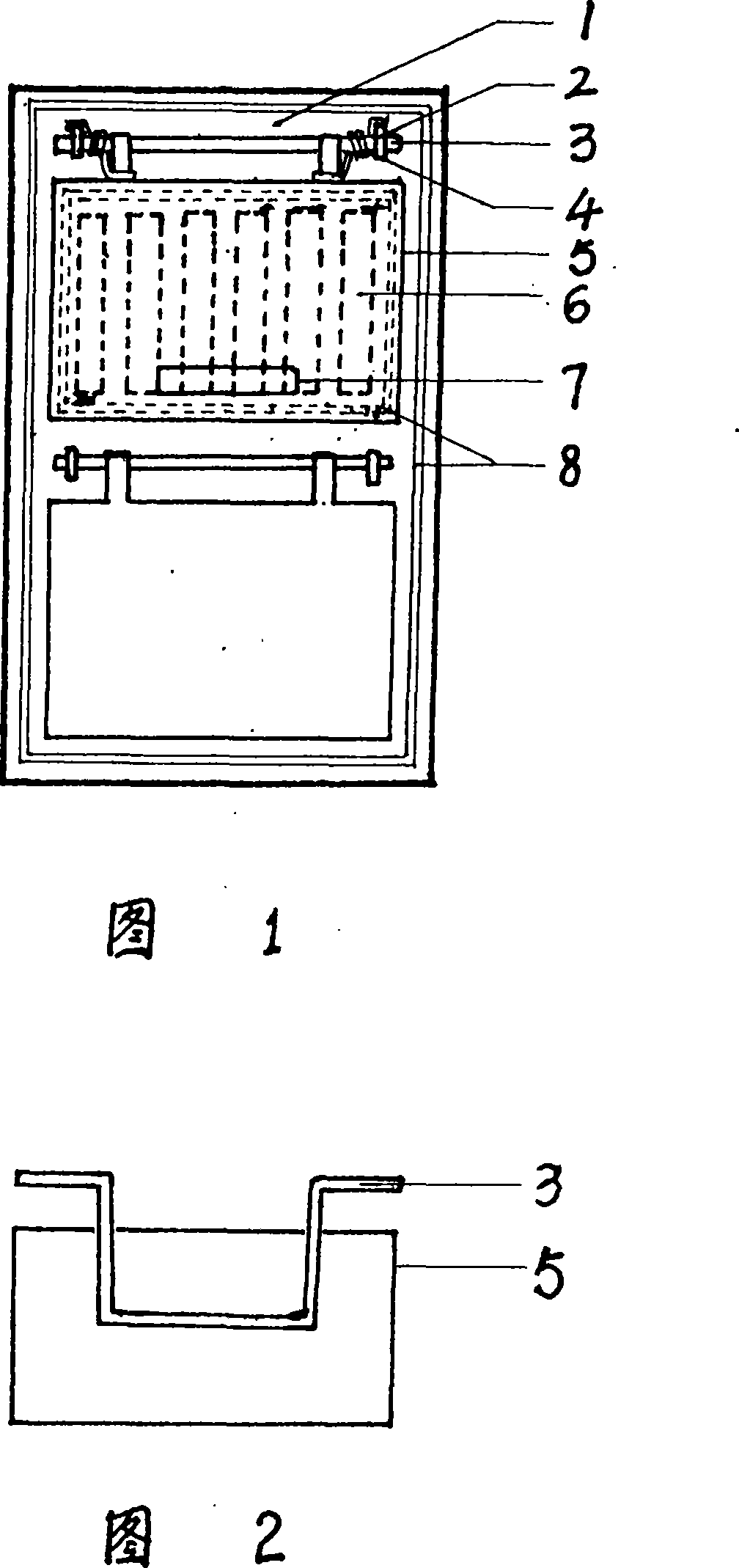

[0009] As shown in Figure 1, a sealing rubber strip 8 is provided at the edge around the back of the grate body 1. This rubber strip can ensure that the turbid air under the grate body 1 does not escape through the four frames of the grate body and the contact surface of the grate seat. The strips can be bonded or embedded in the processed groove; the sealing sheet 5 is a thin sheet corresponding to the hole 6 on the grate to be blocked, which can block all the holes on the entire grate in a single piece. Corresponding seals can also be set for one row, several rows, one column, several columns or every two rows, one or several holes in a column, and around one or more holes corresponding to the seals on the back grate. Adhesive strip 8 is provided, and this adhesive strip can also be installed on the sealing sheet, which can ensure that the turbid air does not escape from the drain hole 6; in order to increase the strength of the sealing sheet, a rib-shaped object or Stamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com