Driver of washer

A driving device and washing machine technology, applied in the field of washing machines, to achieve the effects of increasing output, excellent waterproofness, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

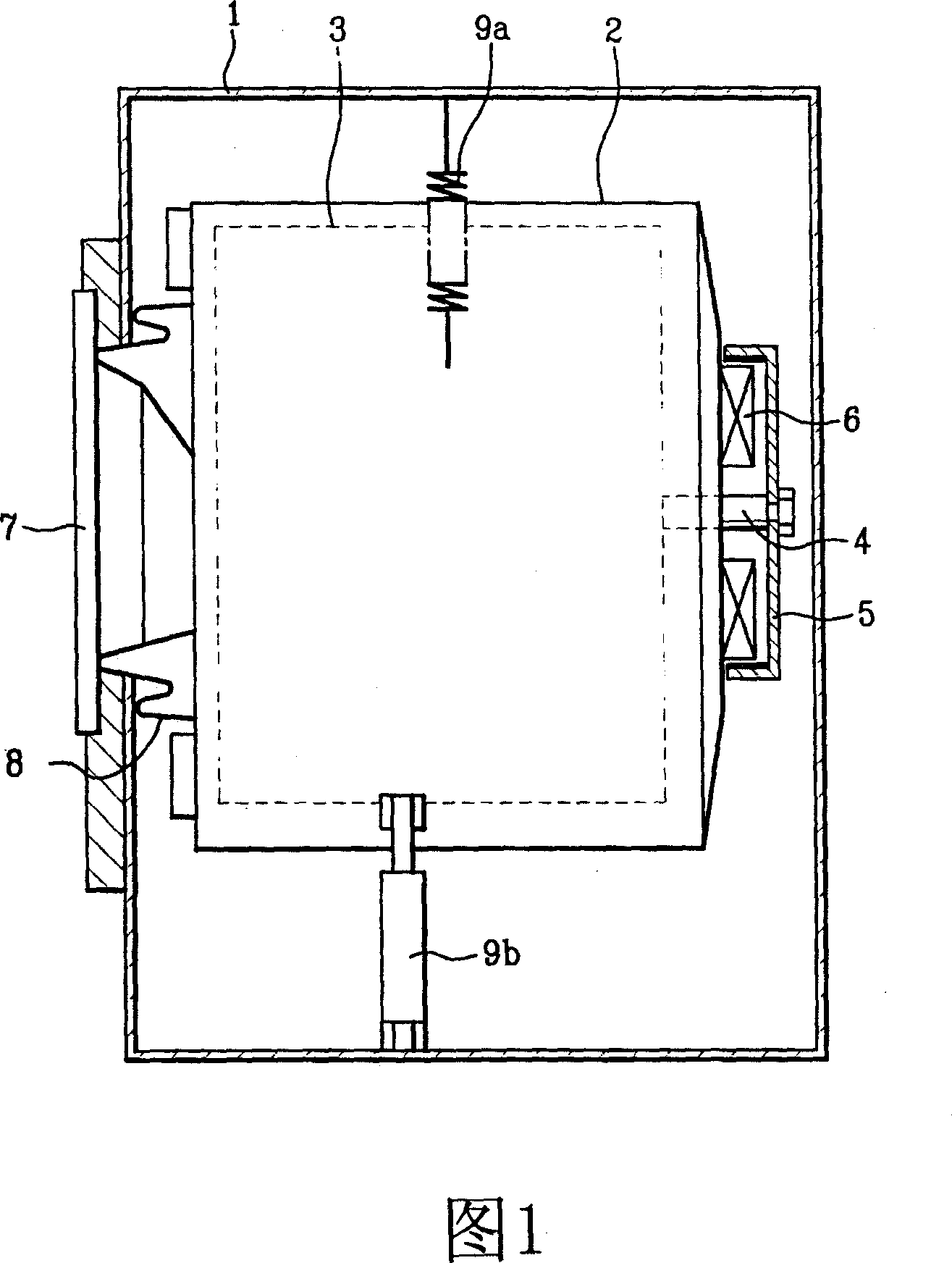

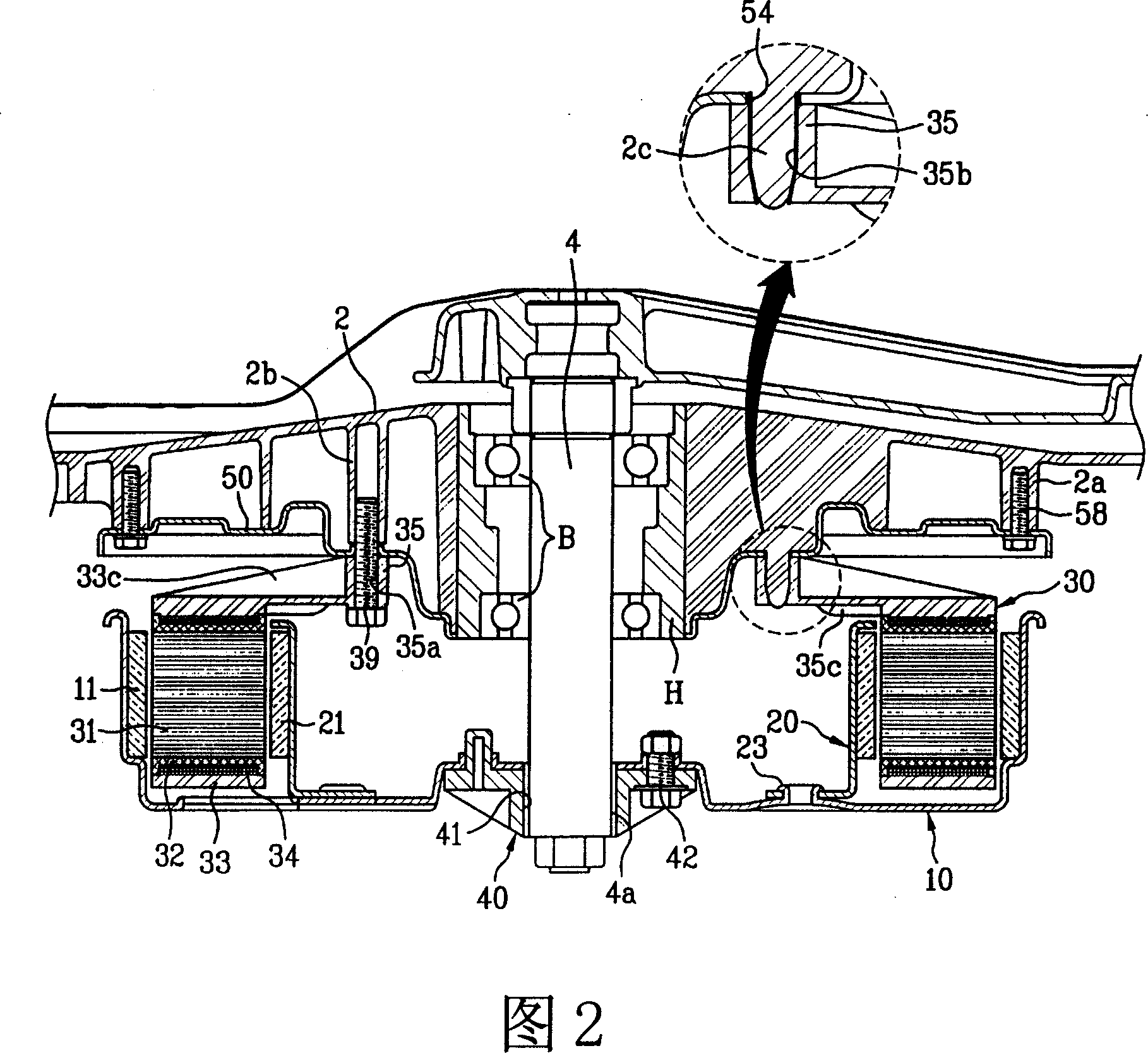

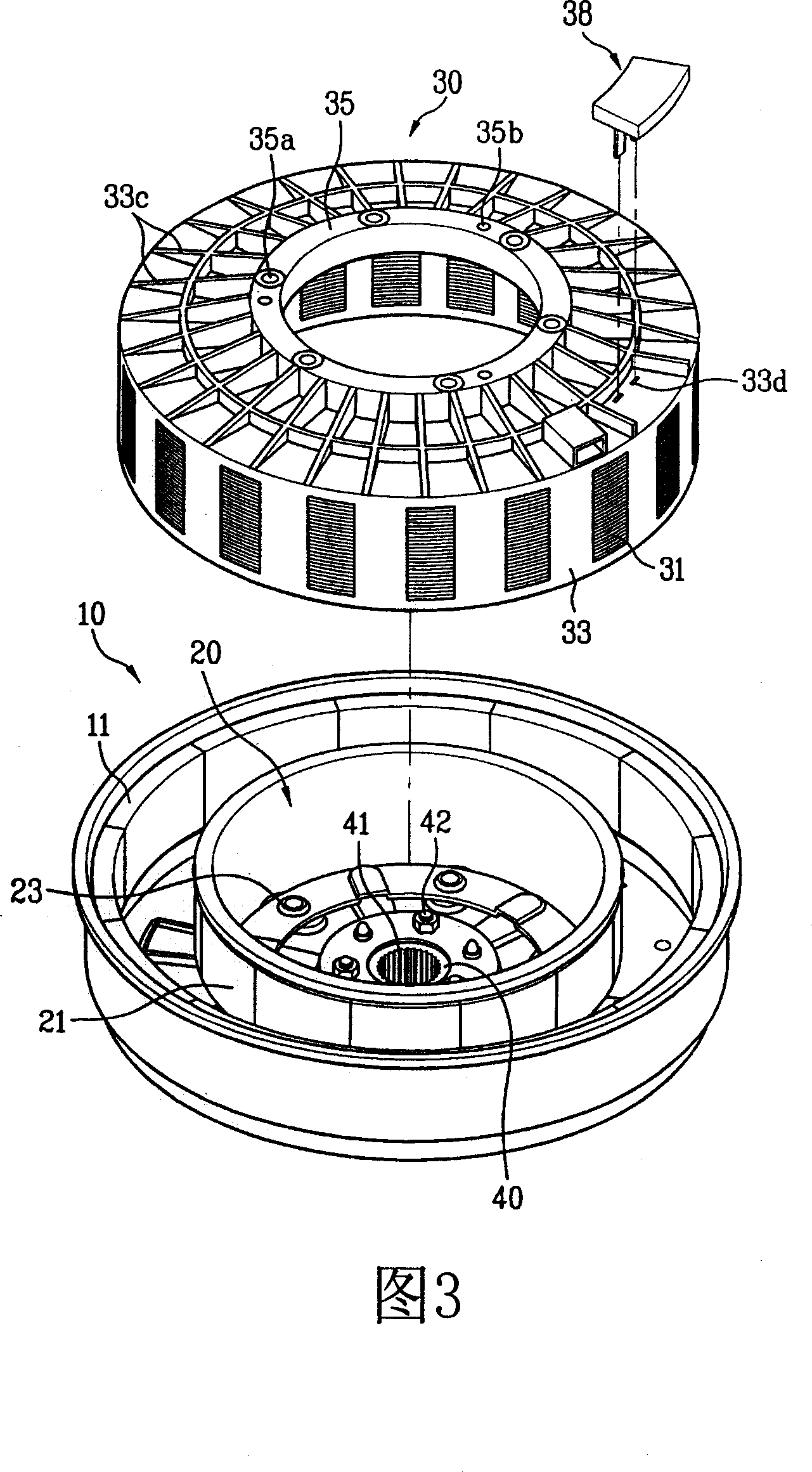

[0042] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

[0043] ***Description of symbols for main components in the drawings***

[0044] 2: Barrel 2a: Bracket connection bushing

[0045] 2b: Stator connection bushing 2c: Projection for position determination

[0046] 3: Roller 4: Roller shaft

[0047] 10: Outer rotor 11: Magnet

[0048] 20: Inner rotor 21: Magnet

[0049] 30: Stator 31: Iron core

[0050] 32: Insulator 33: Mold part

[0051] 34: coil 35: fixed part

[0052] 35a: Connection hole 35b: Position determination hole

[0053] 37: Connector 38: Hall sensor

[0054] 40: Sleeve 50, 250: Bracket for motor fixing

[0055] 60: Auxiliary bracket

[0056] Referring to Fig. 2 and Fig. 3, a drum shaft 4 is extended rearwardly in the center of the rear portion of the drum 3 (see Fig. 1). A bearing housing H is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com