Latent heat storing device

A storage device, latent heat technology, applied in the direction of heat storage equipment, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of difficult to manufacture and handle, expensive and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

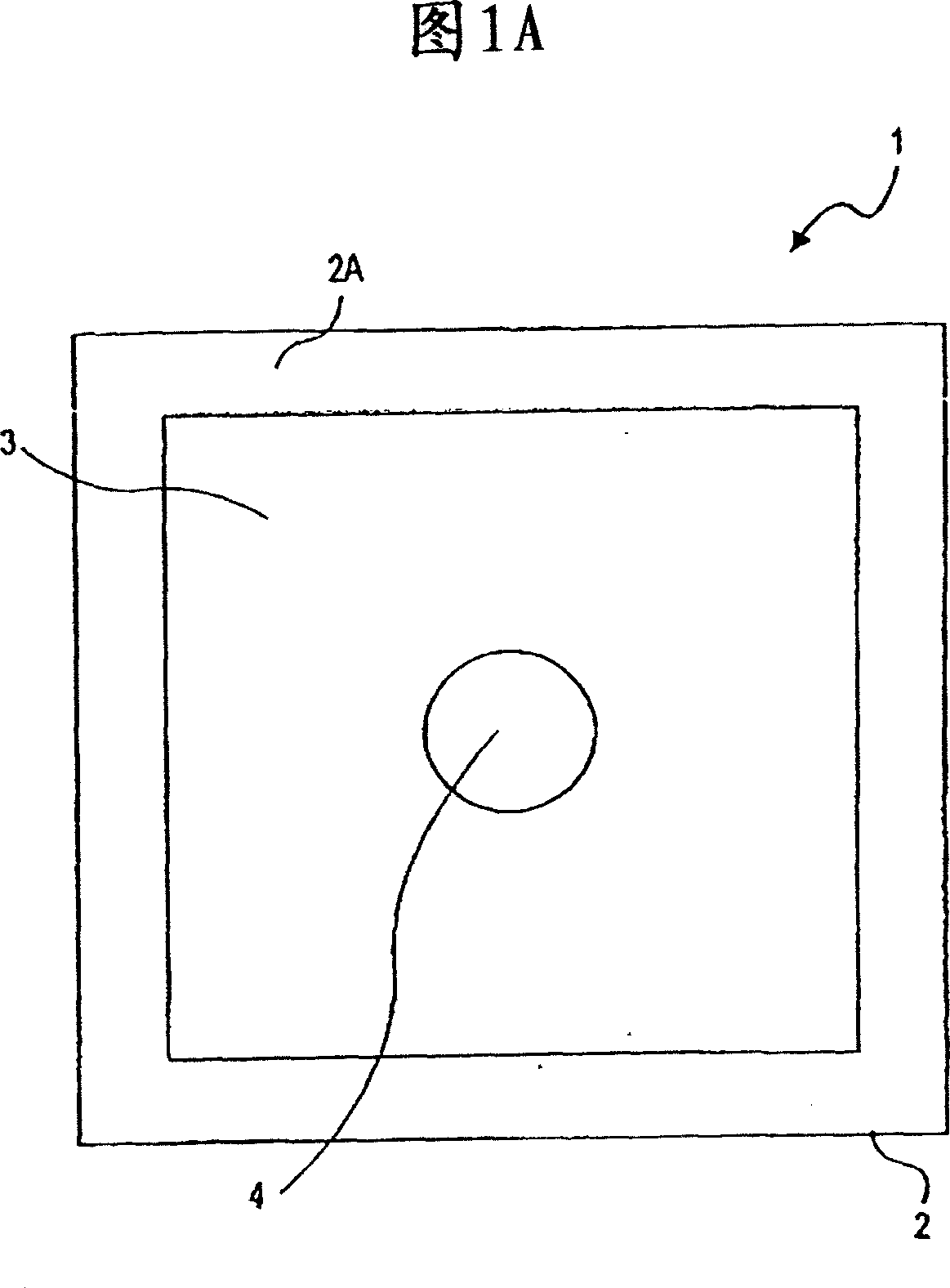

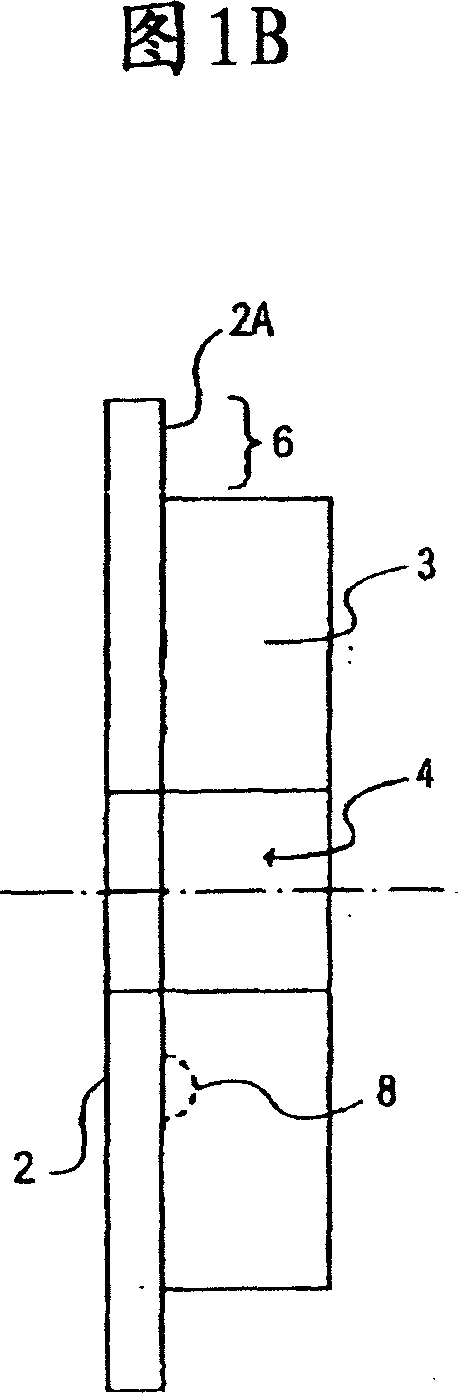

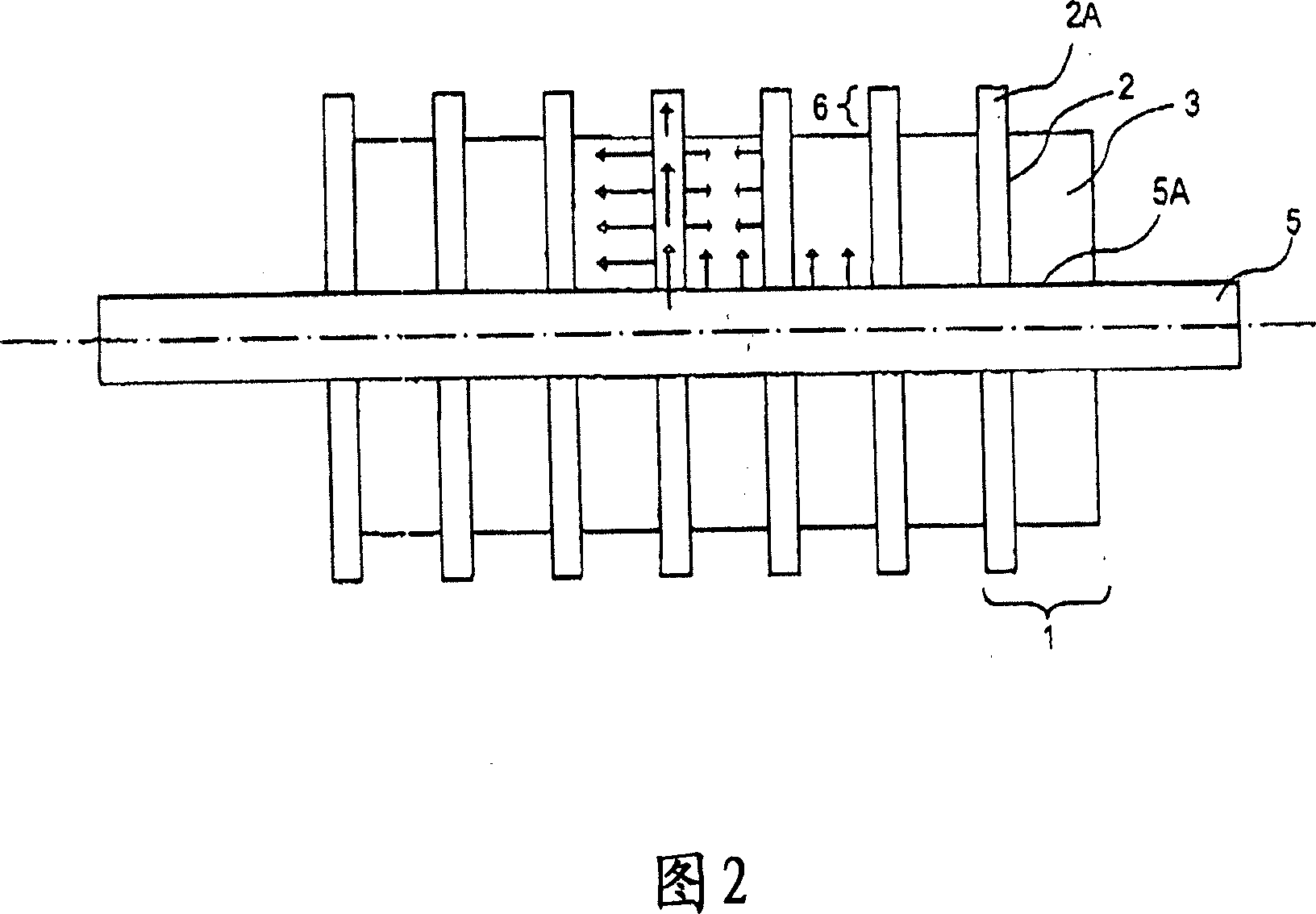

[0038] Figures 1A and 1B show, respectively, a front view and a side view of a layered composite (laminate) 1 comprising a graphite flake layer 2 and a phase change material (PCM) layer 3 in solid state. In the center of the laminate there is a through hole 4 allowing the laminate 1 to be placed on the heat exchange tubes.

[0039] In the embodiment shown in FIGS. 1A and 1B , the graphite flake layer 2 has a larger surface area than the phase change material (PCM) layer 3 in solid state. FIG. 1A shows a rectangular laminate 1 with a graphite flake layer 2 having a larger surface area than a layer 3 of phase change material. A representative size of laminate 1 is 350 x 350 x 0.5mm 3 The sheet layer 2 and 320×320×5~10mm 3 Layer 3. The difference in surface area is indicated by edge 2A. The space 6 defined by the edge 2A of the graphite flake layer 2 protruding beyond the edge of the phase change material layer 3 can be filled when the volume of the phase change material incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com