Two-component heat storage encapsulating material and preparation method thereof

A potting material and two-component technology, applied in the field of two-component heat storage potting materials and their preparation, can solve the problems of high cost, easy overflow, good fluidity, etc., and achieve the increase of phase change enthalpy, cost reduction, The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

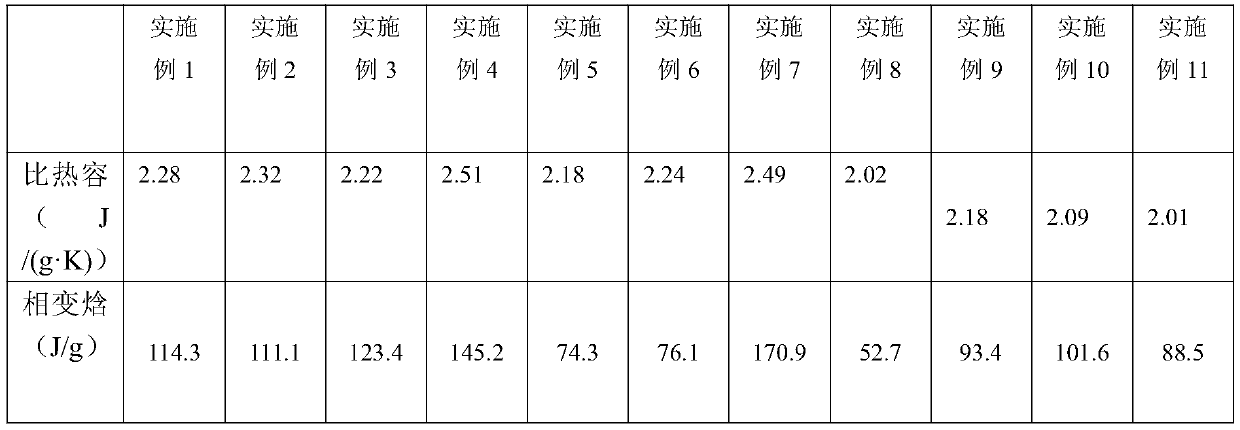

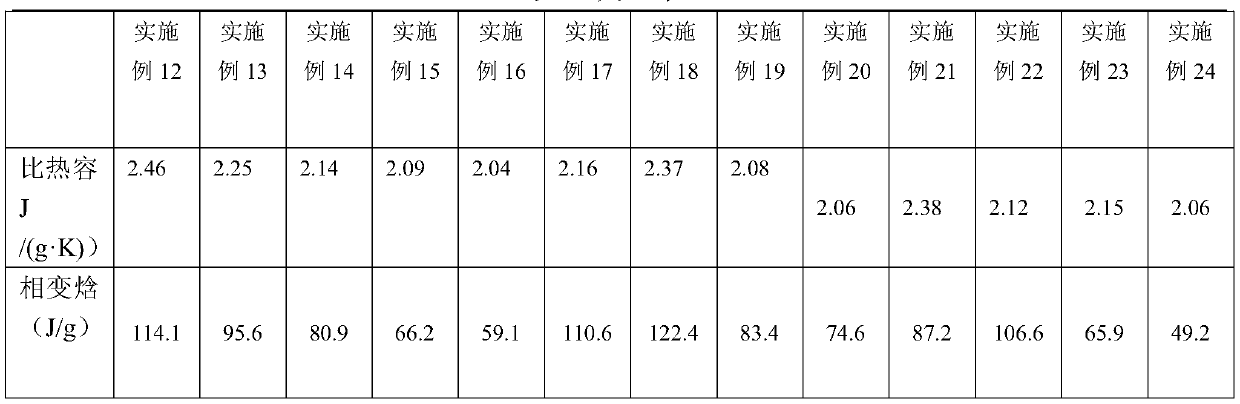

Examples

Embodiment 1

[0037] Two-component heat storage potting material, including the following components by weight: Component A: 20 parts of acrylic resin, 20 parts of phase change material and 0.2 part of stannous octoate; Component B: 20 parts of polyurethane curing agent, phase 20 parts of change material, the weight ratio of A component and B component is 1:1, wherein, the phase change material is graphite adsorption phase change energy storage powder, and the graphite adsorption phase change energy storage powder includes the following Each component in parts by weight: 100 parts of paraffin and 5 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 500ml / g, the particle size is 100 mesh, the expansion multiple is 400 times, and the bulk density is 0.2g / cm 3 .

Embodiment 2

[0039] Two-component heat storage potting material, including the following components by weight: Component A: 70 parts of acrylic resin, 70 parts of phase change material and 0.6 part of stannous octoate; Component B: 70 parts of polyurethane curing agent, phase 70 parts of change material, the weight ratio of component A and component B is 1:1, wherein, the phase change material is graphite adsorption phase change energy storage powder, wherein graphite adsorption phase change energy storage powder includes the following Each component in parts by weight: 100 parts of paraffin and 9 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 600ml / g, the particle size is 200 mesh, the expansion multiple is 600 times, and the bulk density is 0.5g / cm 3 .

Embodiment 3

[0041]Two-component heat storage potting material, including the following components by weight: Component A: 20 parts of polyurethane resin, 20 parts of phase change material and 0.2 part of stannous octoate; Component B: 20 parts of polyurethane curing agent, phase 20 parts of change material, the weight ratio of component A and component B is 1:1, wherein, the phase change material is graphite adsorption phase change energy storage powder, wherein graphite adsorption phase change energy storage powder includes the following Each component in parts by weight: 100 parts of fatty acid and 6 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 100ml / g, the particle size is 150 mesh, the expansion multiple is 500 times, and the bulk density is 0.3g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com