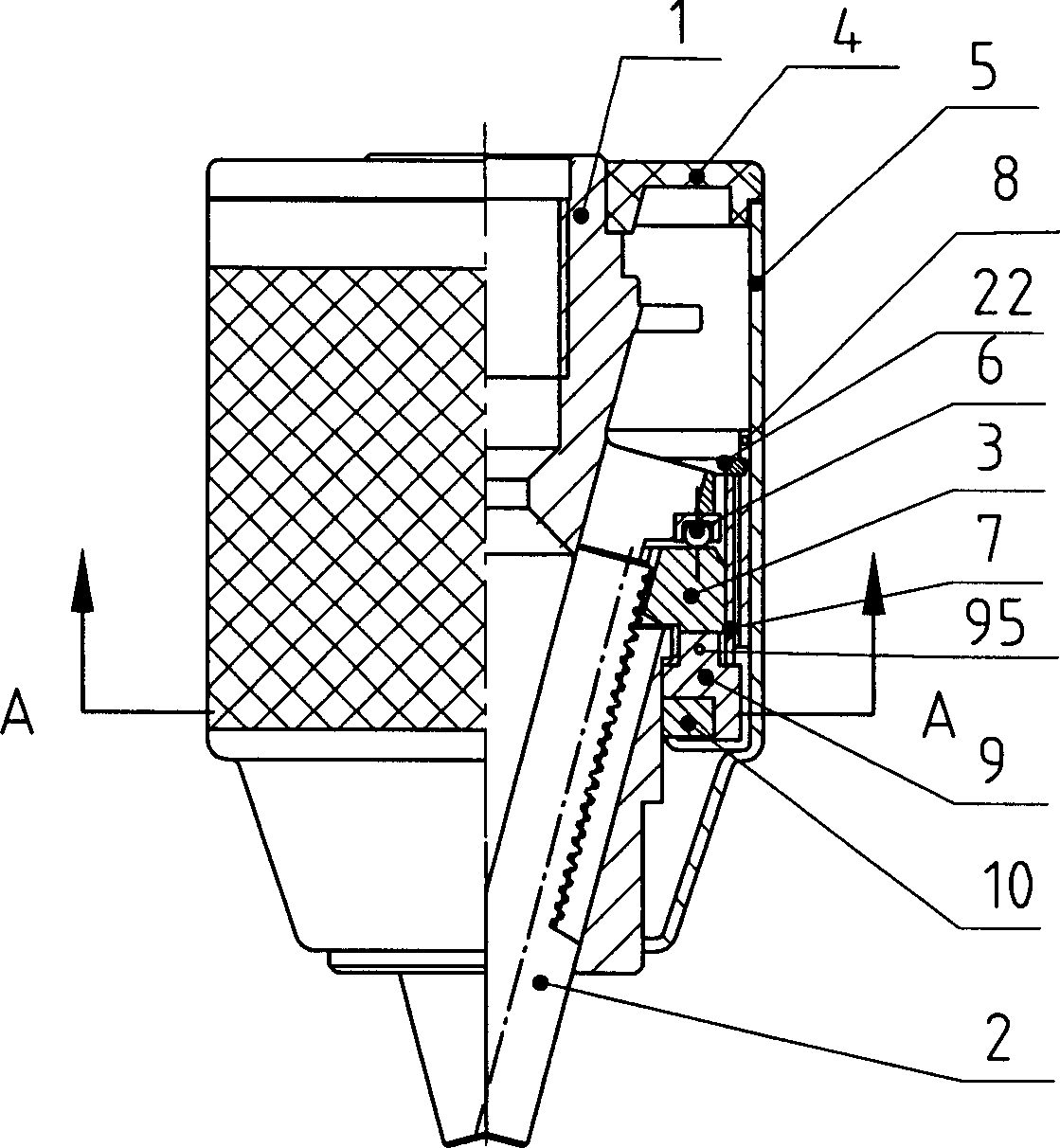

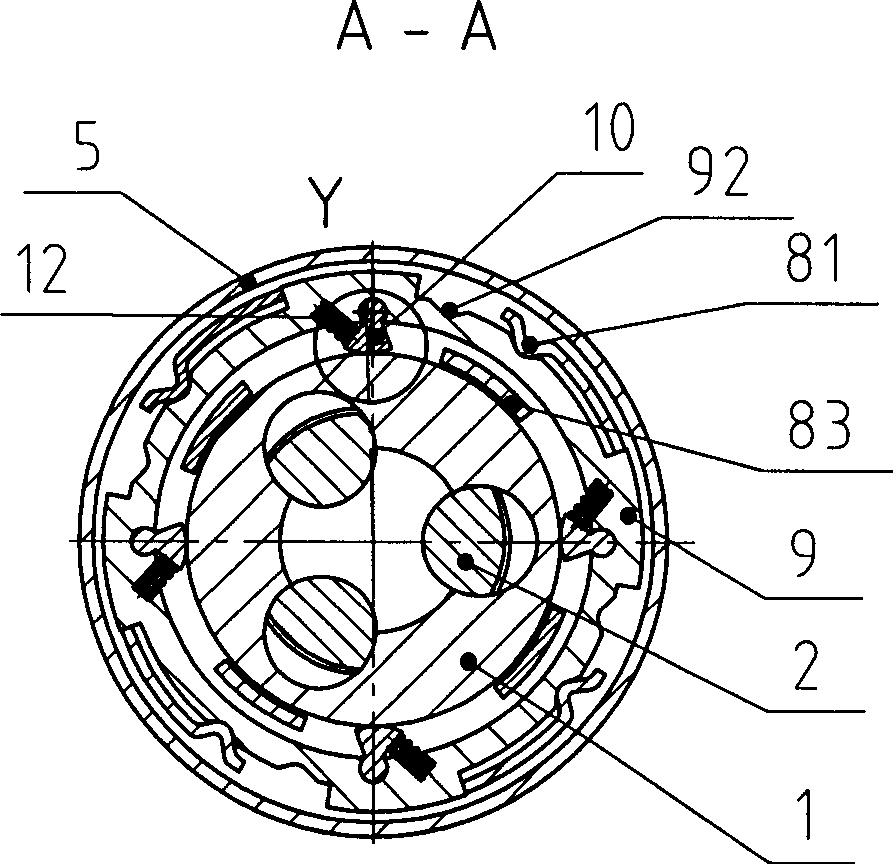

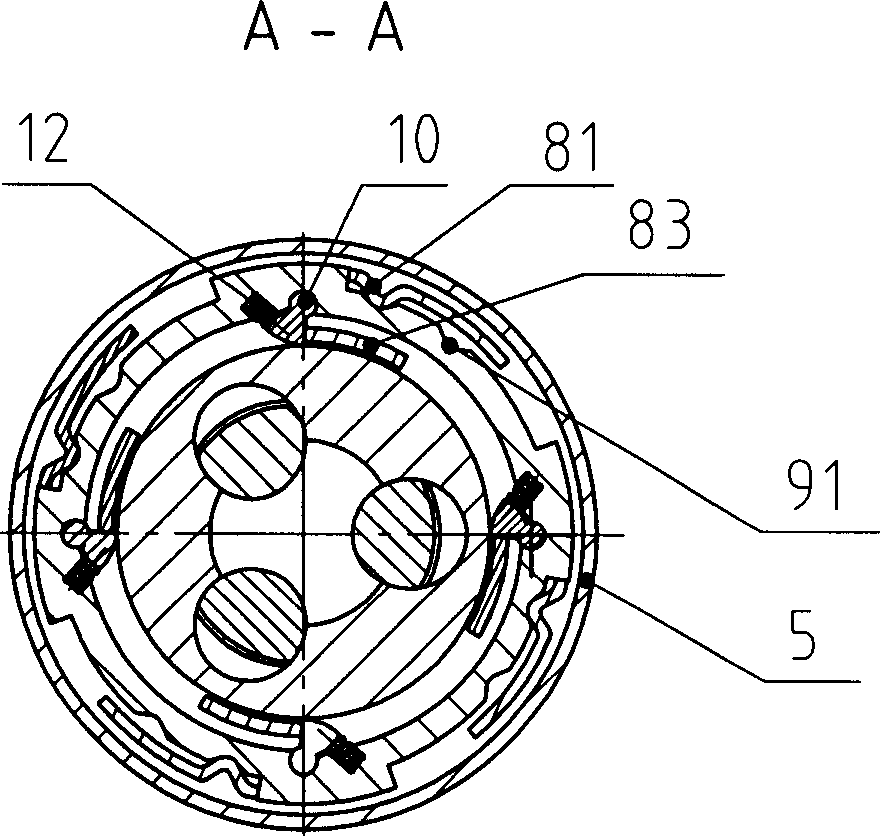

Slanting wedge face locking drill clamping chuck

A technology of inclined wedge surface and drill chuck, which is applied to the accessories of tool holder, chucks, turning equipment, etc., can solve the problems of easy loosening of nuts and production obstacles.

Inactive Publication Date: 2010-12-01

SHANDONG WEIDA MASCH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the drill chuck generally works under the condition of vibration and shock, due to inertia, the nut is easy to loosen, so that the jaws loosen the tool handle

Therefore, in operation, it is necessary to tighten the nut repeatedly, which hinders production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 example

no. 2 example

no. 3 example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses one kind of tapered wedge locked drill chuck, which includes a drill body, clamping jaws, a nut, an outer sleeve, a control sleeve, a pusher dog and a wedge locking ring. The wedge locking ring on the drill body drives the nut to rotate and has wedge block and elastic part pivoted inside it; the control sleeve is connected to the outer sleeve to rotate the wedge locking ring; and the pusher dog rotates synchronously with the control sleeve between the first location with uncoupled wedge block and the second location with contacted wedge block. The present invention may have rolling locking ring to replace the wedge locking ring to realize friction locking suitable for use under vibration condition.

Description

Bevel Locking Drill Chuck technical field The invention relates to a rotary tool clamping device, in particular to a wedge surface locking drill chuck. Background technique Conventional rotary tool clamping devices are used to clamp various rotary tools, such as drills, reamers, taps, etc. These rotary tools are also known as collets. A typical chuck, such as a drill chuck, includes a drill body, a plurality (eg, three) of jaws, a nut, a housing, etc., and some also include a back sleeve. Additionally, some chucks include bearing assemblies to reduce friction. A plurality of jaws are respectively installed in a plurality of oblique holes equally divided into each other in the drill body. The nut is arranged in the nut groove of the drill body, and cooperates with the thread of the jaw to form a thread transmission mechanism. The outer sleeve is set on the nut (in some cases, the nut is also sleeved with a nut sleeve). The outer cover has a key, and the nut has a key g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23B31/10B23B31/107B23B31/165

Inventor 谭兴达

Owner SHANDONG WEIDA MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com