Tungsten shorting stub and method of manufacture

A technology of short wires and tungsten alloys, which is applied in the direction of cable/conductor manufacturing, conductors, metal/alloy conductors, etc., which can solve the problems of increased overall size of short wires, unacceptable size and material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

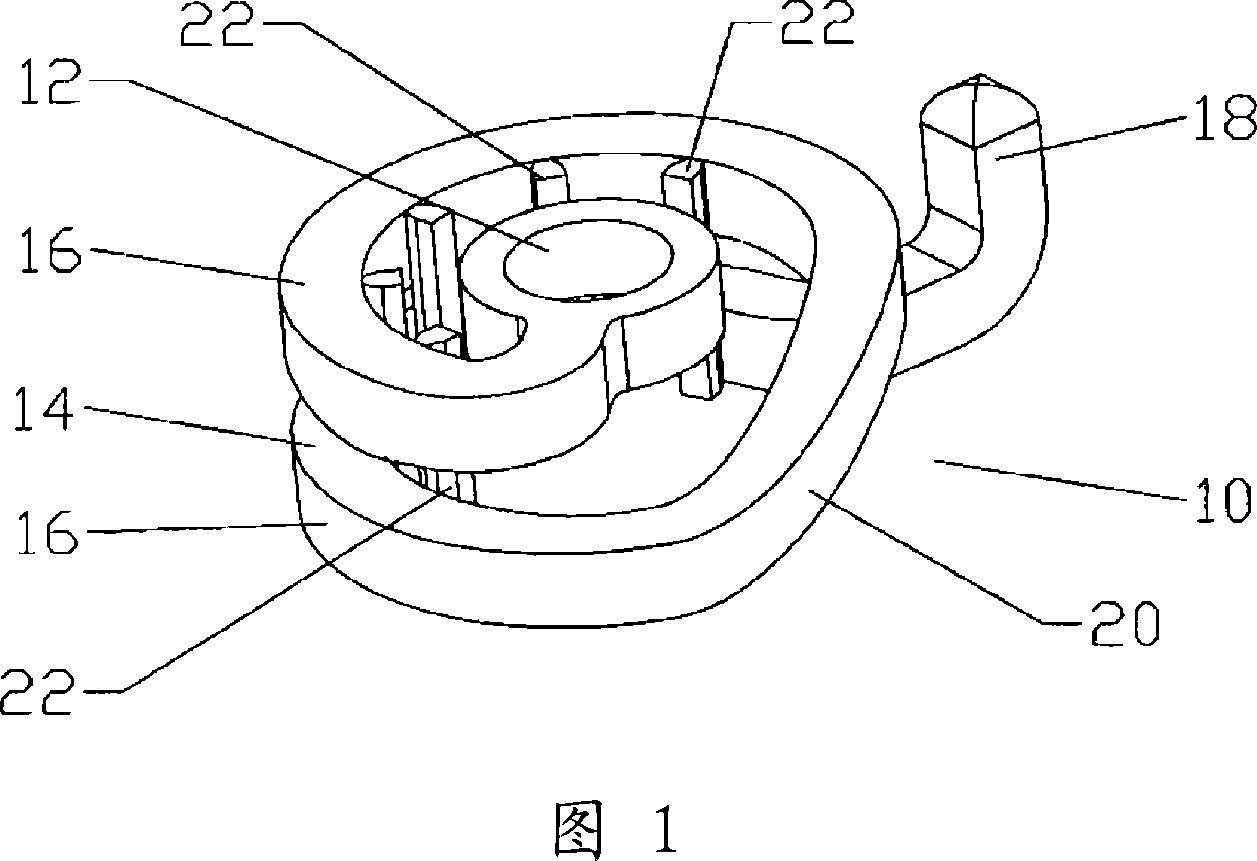

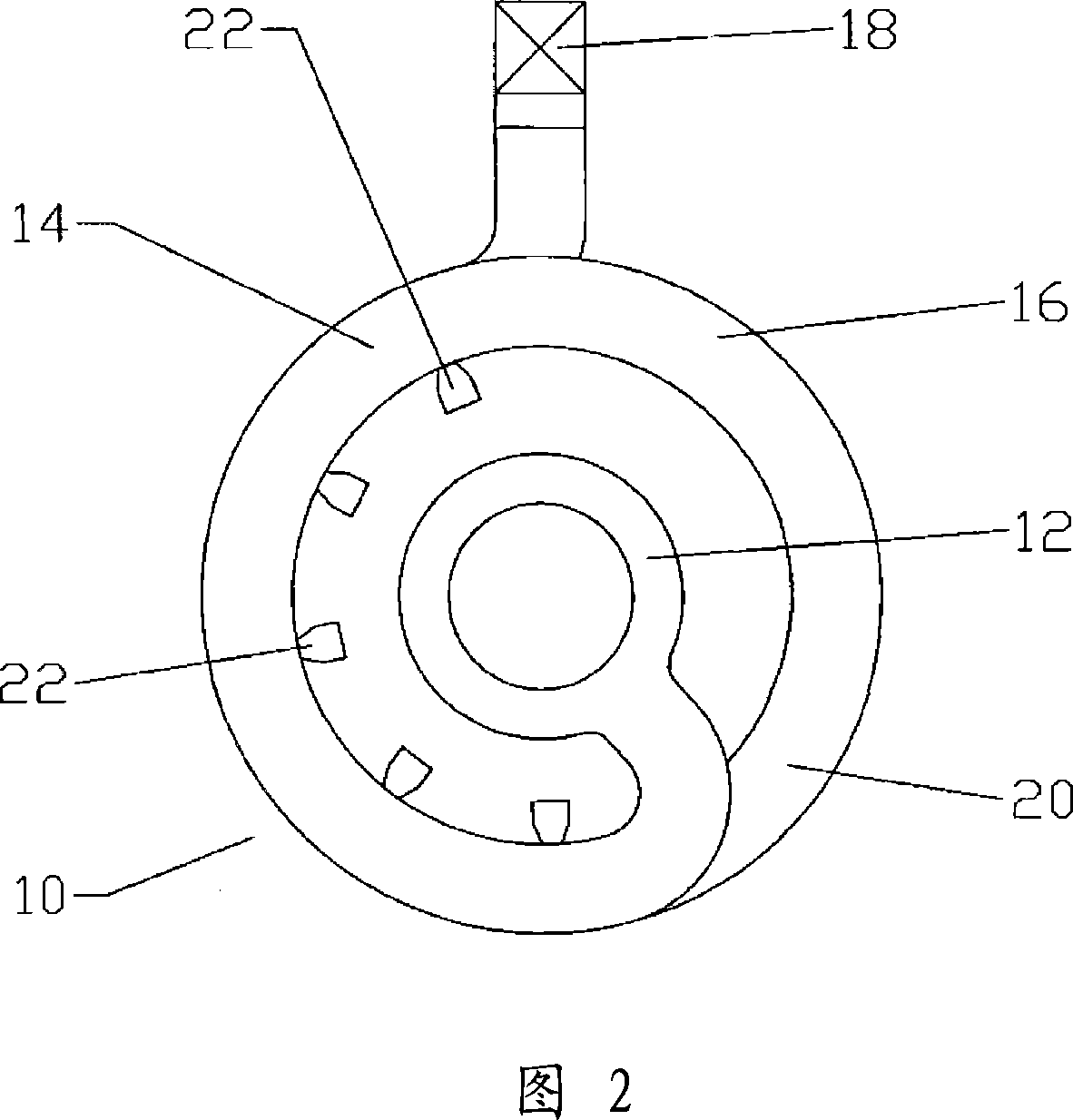

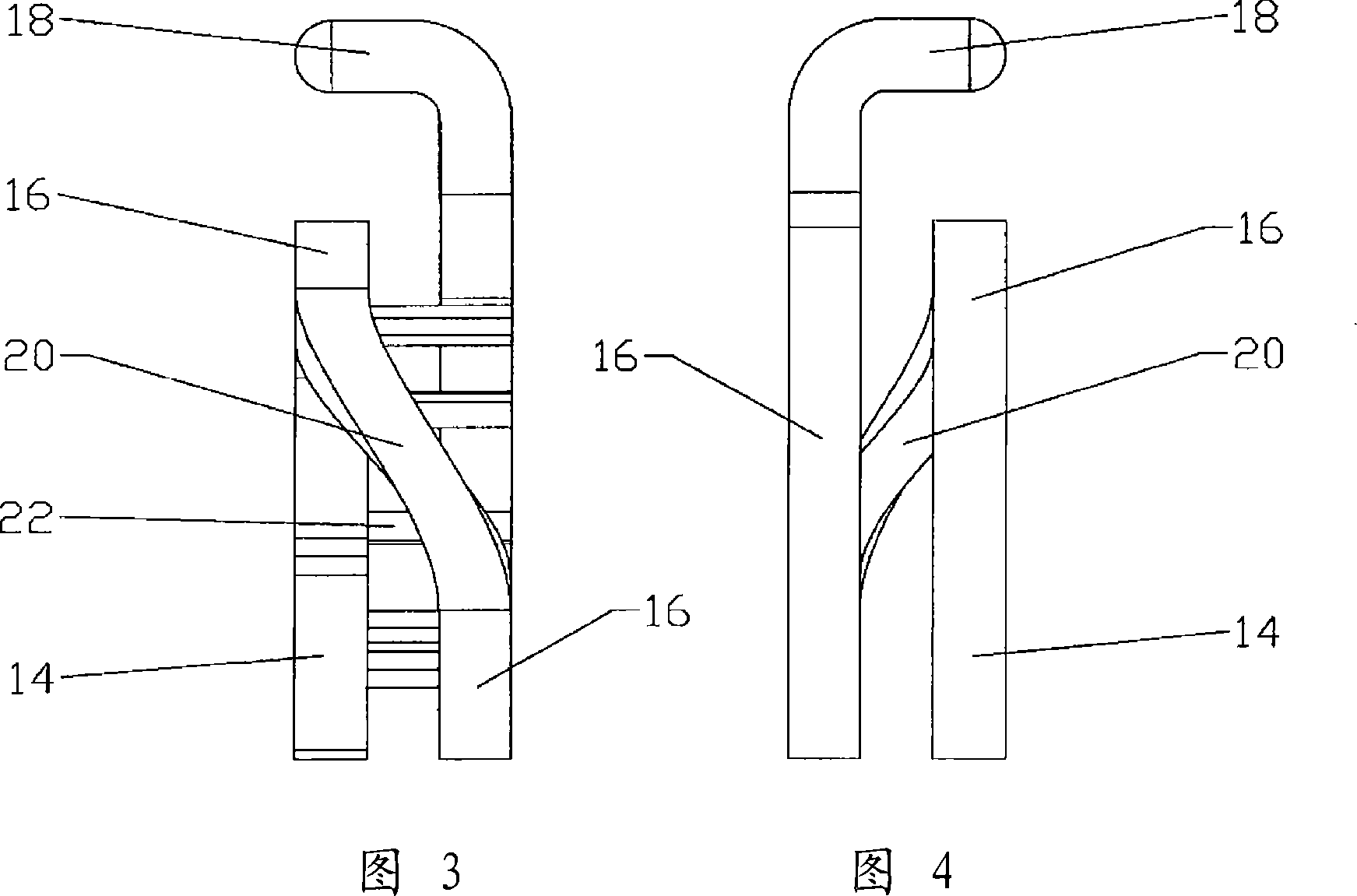

Image

Examples

Embodiment Construction

[0021] The electromechanical properties of tungsten and other metals and / or metal alloys are known as:

[0022] Material Conductivity Elasticity Tensile Yield Thermal Stability

[0023] (%IACS) (PSI) (PSI) (μin / in-℃)

[0024] (CTE) Bronze 28 16+10e 663,100 20.3

[0025] Phosphor bronze 16 16+10e6 74,700 16.0

[0026] Aluminum (7075) 33 10.3+10e6 73,000 23.2

[0027] Tungsten 30 59.5+10e6 109,000 4.6

[0028] Although shorting wires can withstand relatively high power surge events, deformation of the shorting wires caused by the surge event can destroy the electrical performance of the working shorting wires. The inventors have recognized that, within the constraints of common assembly dimensions, a major limitation in designing shorts with higher surge resistance is the electromechanical properties of the materials used for the shorts.

[0029] While almost as conductive as aluminum (high conductivity is a desirable property because it reduces the resulting "...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap