Structure d'enveloppe de protection pour un pilon

A protection cover and rammer technology, applied in the field of protection cover, can solve the problems of unstable posture, inability to work, easy to overturn, etc., and achieve the effects of elasticity, reduced damage, and prevention of damage to the prime mover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

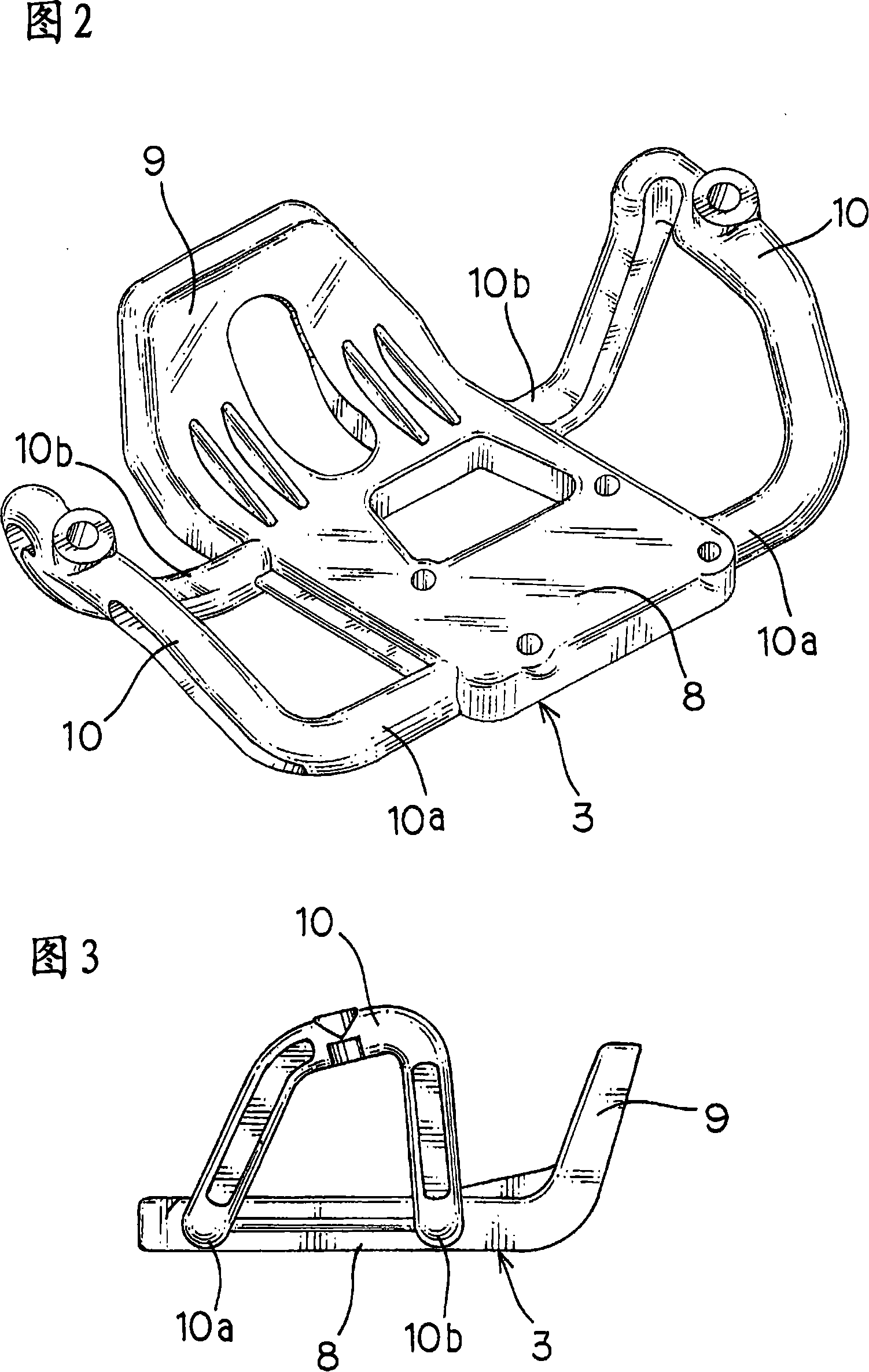

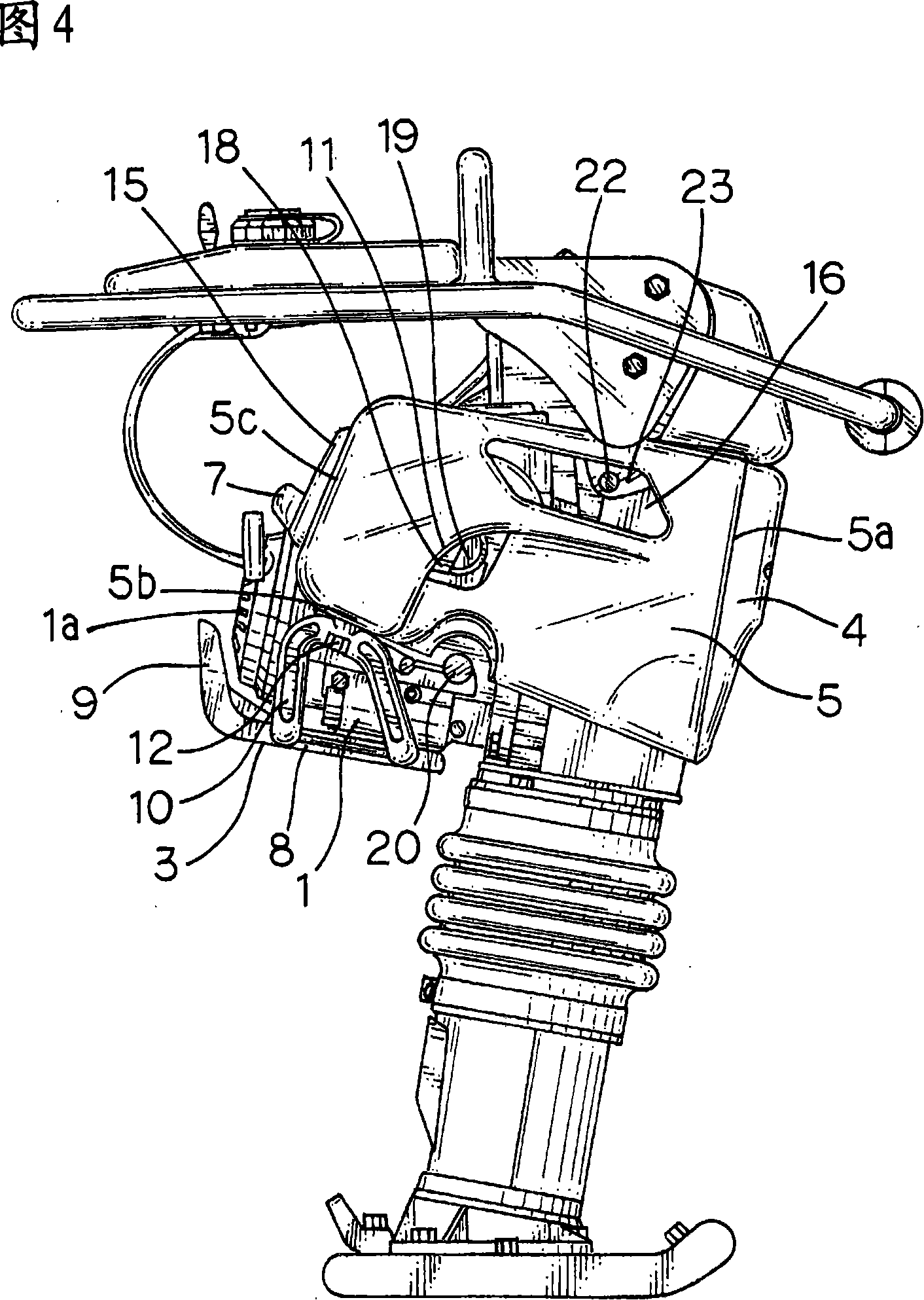

[0024] After the front end of the crank chamber side is joined to the peripheral portion of the front panel of the crank chamber, the protective cover supports the lower side of the prime mover on the support frame of the protective seat provided on the lower surface of the prime mover. Fix it on the support frame of the protective seat with bolts to complete the basic configuration operation of the protective covers on both sides, but for the sake of strengthening, it is better to insert the bolts from the outside of the vent hole to the inside of a part of the vent hole. Securely fix the protective cover on the wall of the crank chamber in the threaded hole.

[0025] (Example)

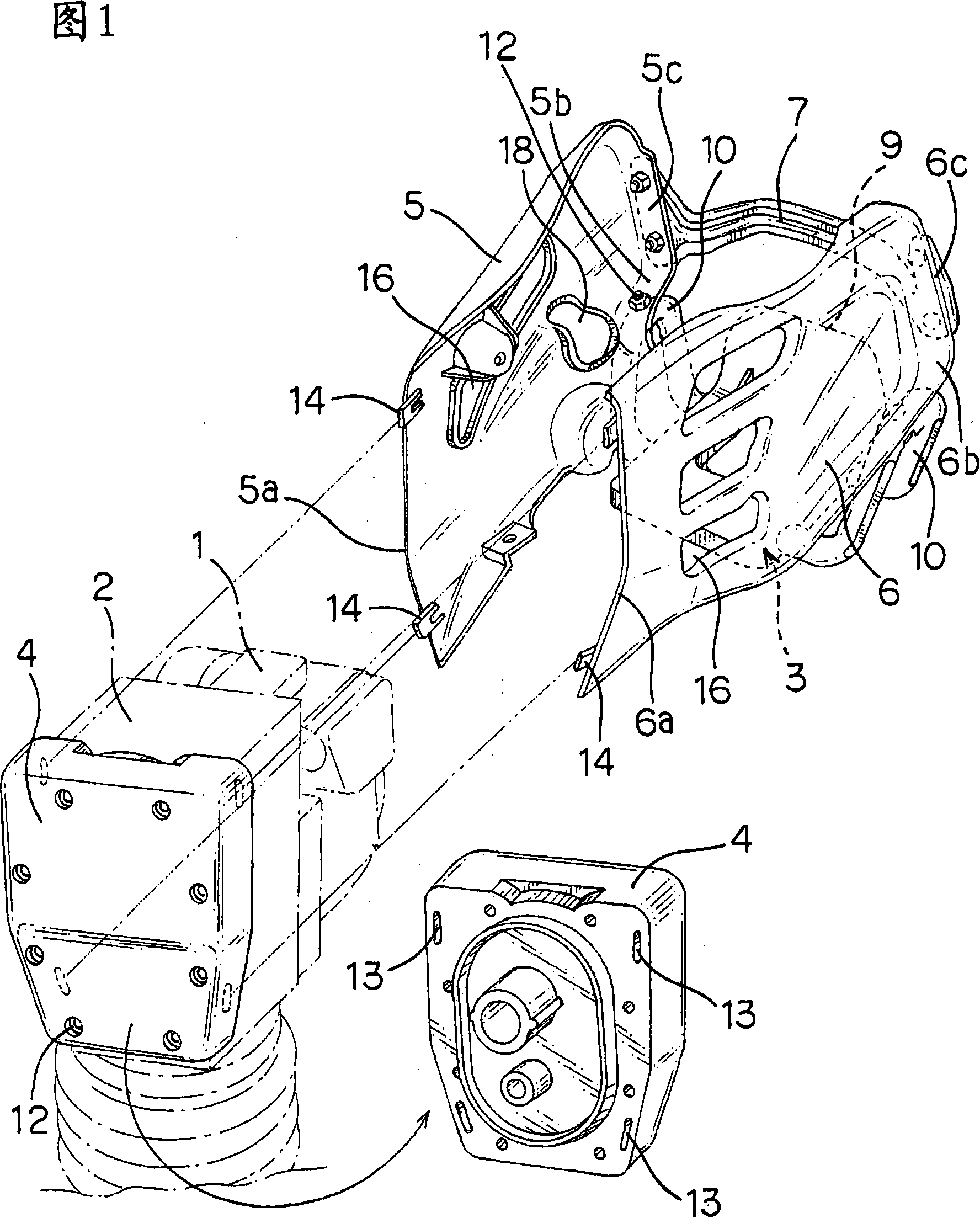

[0026] Next, the protective cover structure of the rammer involved in the present invention will be described with the help of the embodiment shown in FIG. 1. FIG. 1 is an axonometric view showing the basic composition of the protective cover structure. The protective cover structure includes: The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com