Table top positioning mechanism for plate drilling machine

A positioning mechanism and drilling machine technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of easy penetration and breaking, and achieve the effect of stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

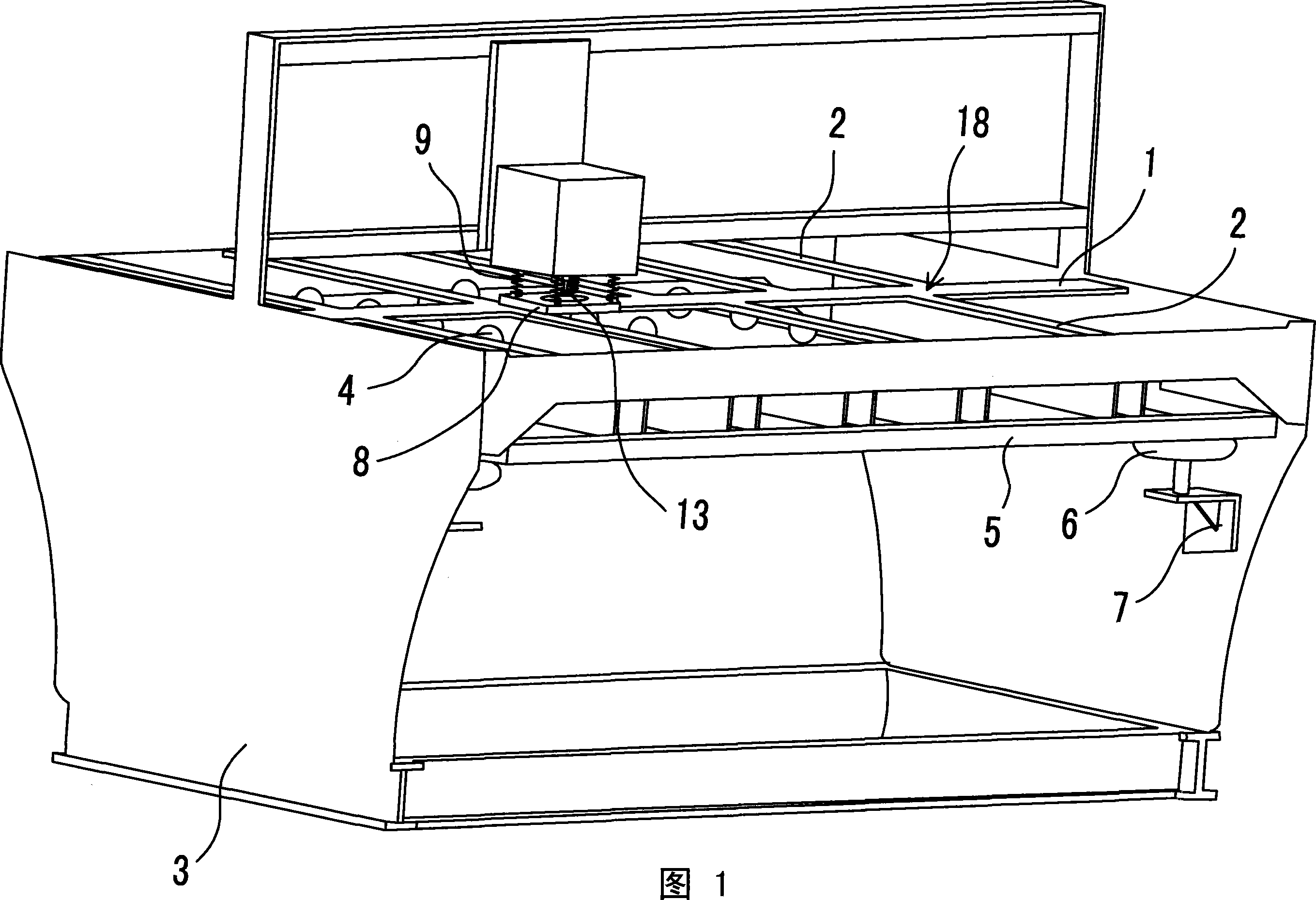

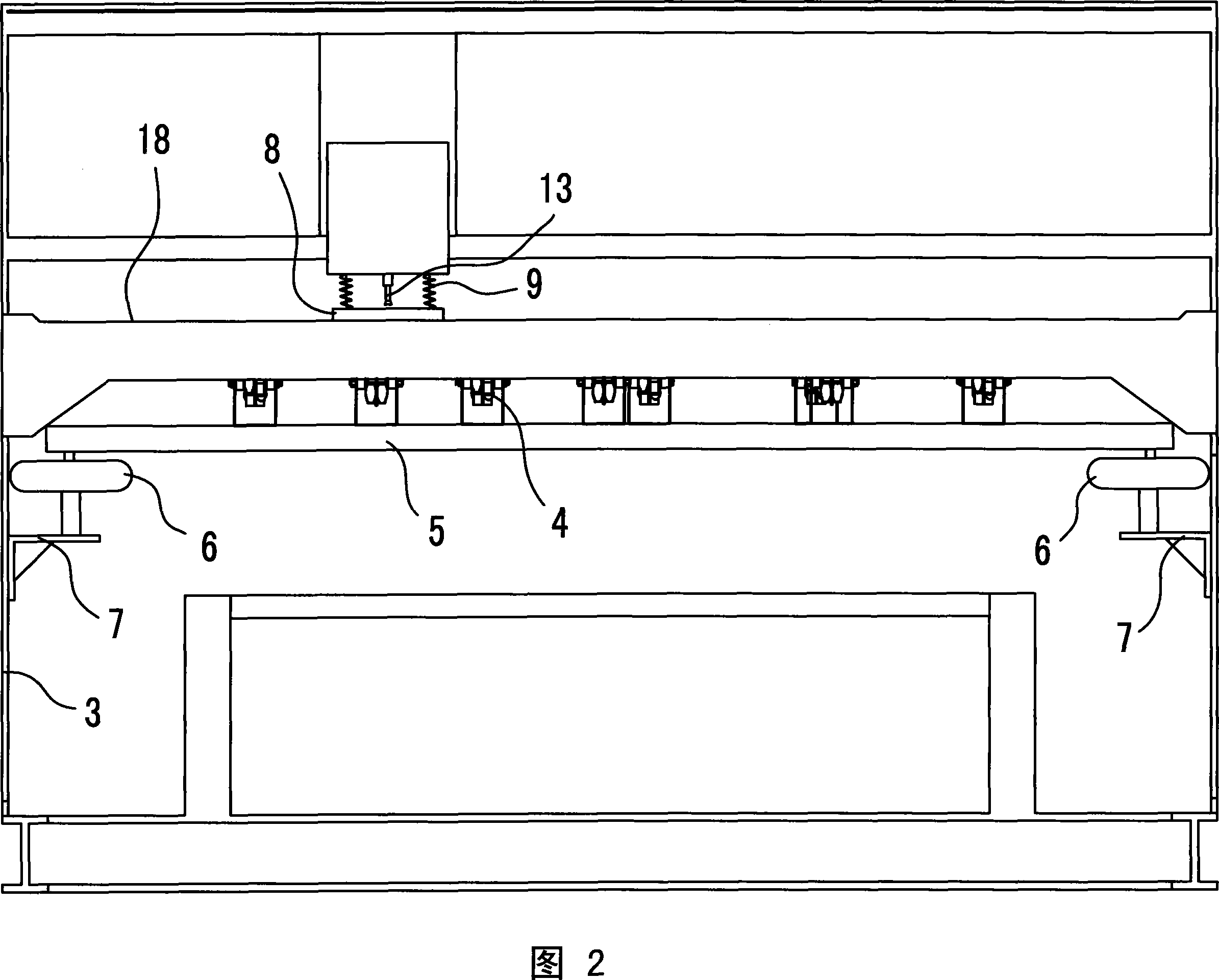

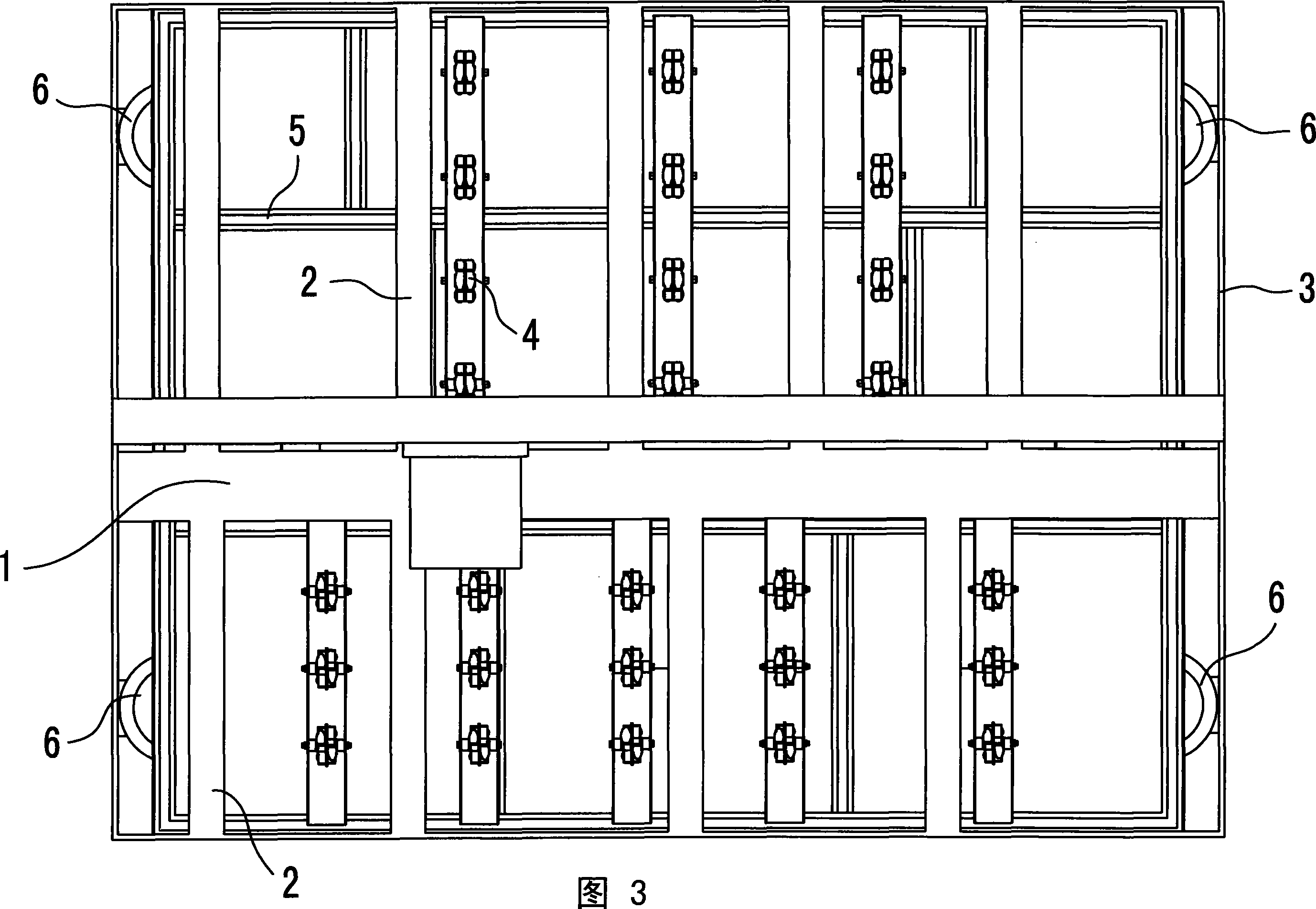

[0029] Embodiment: A table positioning mechanism suitable for a fully automatic or semi-automatic plate drilling machine is composed of three parts: a plate horizontal support mechanism, an elastic platen pressing mechanism and a plane positioning mechanism.

[0030]As shown in Fig. 1, Fig. 2 and Fig. 3, the horizontal support mechanism for the plate is composed of a dislocation combination of a fixed support table 18 and a lifting roller support table. The fixed support table 18 is provided with a main support plate 1 arranged along the X direction (horizontal and transverse direction of the front of the complete machine), and the main support plate 1 is located directly below the drill bit 13 in the Y direction (horizontal and longitudinal direction of the front of the complete machine), so that the drill bit 13 can punch holes. When the action point falls on the main support plate 1 all the time, in other words, the main support plate 1 bears the horizontal support function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com