Tool body making process

A technology of a tool body and a manufacturing method, which is applied in the field of manufacturing methods and their products that can simplify the manufacturing process and reduce the cost, and achieve the effects of reducing the defect rate, reducing the cost expenditure, and increasing the frictional force.

Inactive Publication Date: 2010-11-10

胡厚飞

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a method of manufacturing a tool body and its products, which can solve the problems in the prior art. The technical problem to be solved is that the existing tool body will leave many depressions on the surface after cleaning the surface. Therefore, the tool body must be ground before electroplating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

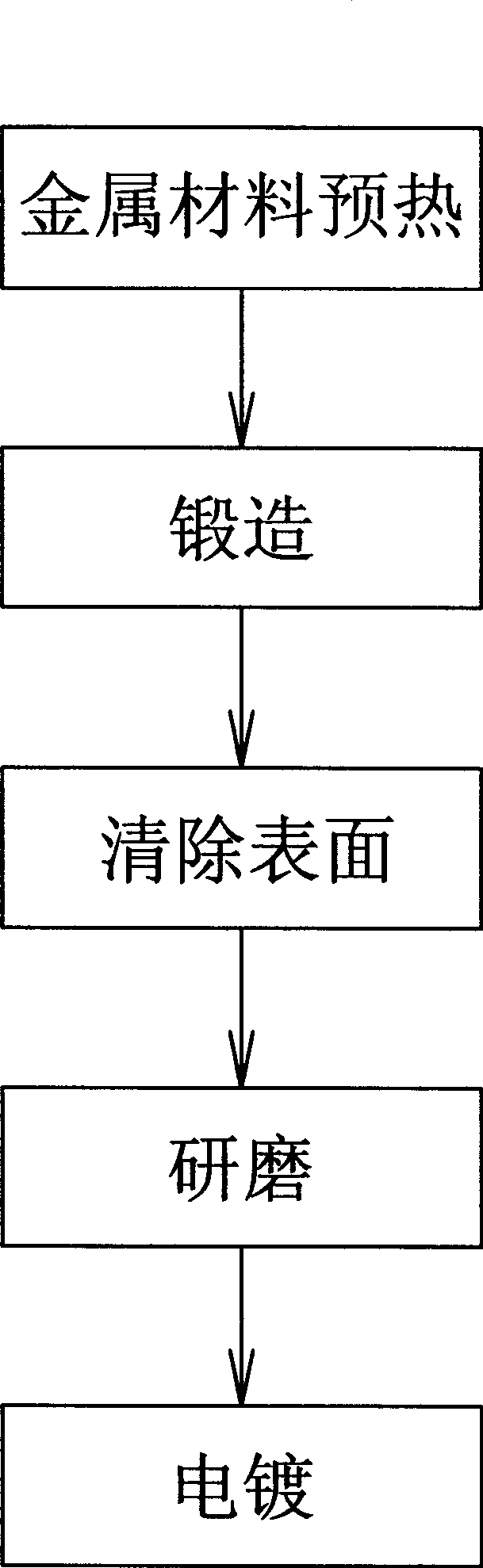

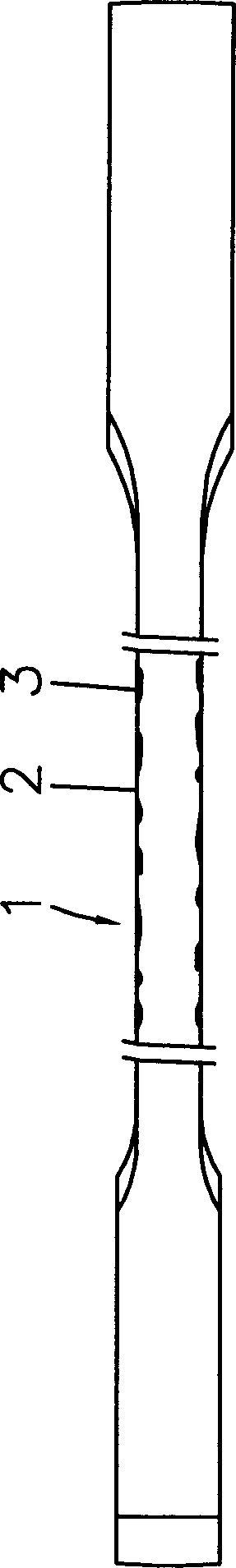

The present invention relates to tool body making process and product. The making process includes preheating metal material, forging, surface treatment and other steps. During forging, the tool body is also embossed synchronously, and this can mask the notch caused in the decarburizing layer, omit the grinding step, form high texture, low production cost and increase surface friction force.

Description

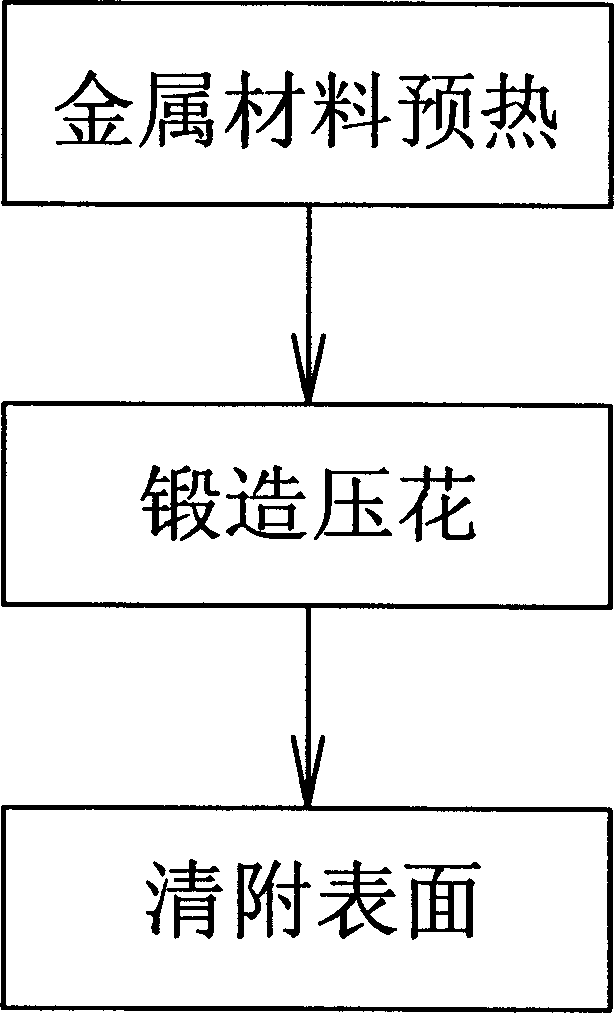

Manufacturing method of tool body technical field The invention relates to a manufacturing method of a tool body and its products, in particular to a manufacturing method and its products which can simplify the manufacturing process and reduce costs. Background technique With the development and progress of science and technology, people's requirements for things have changed from the old thinking of "just use it" to quite delicate and demanding. Only the idea of continuous improvement or innovation will produce new forms to improve the quality of products. Only by adding value and effectively reducing costs can we survive under the test of fierce market competition. Figure 1 is the manufacturing flow chart of the existing tool body. The existing tool body is made by hot forging in order to obtain better strength. The manufacturing process is metal material preheating, forging, surface cleaning, grinding, electroplating, etc. step. However, the metal material will pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25G1/10B25B13/56B21J1/06B25B23/16B21J5/06

Inventor 胡厚飞

Owner 胡厚飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com