Tool body making process and product

A tool body and manufacturing method technology, applied in the direction of manufacturing tools, hand-held tools, metal processing equipment, etc., can solve the problems of increasing the defect rate of the tool body 1, increasing cost expenditure, and being difficult to use and practical, and achieve a noble embossed texture , reduce cost expenditure, and reduce the effect of non-performing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

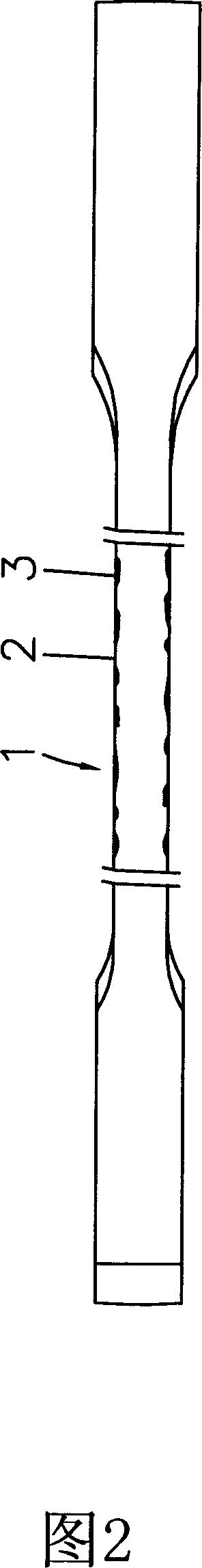

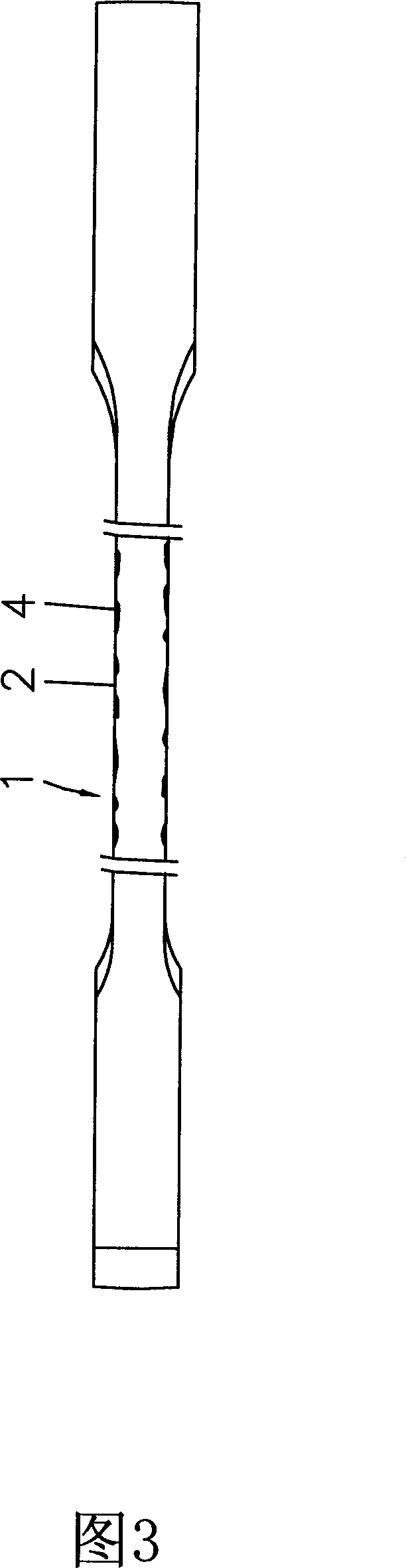

[0025] About the technique adopted in the present invention, means and effect thereof, give a preferred embodiment and cooperate with drawings to describe in detail as follows:

[0026] Please refer to FIG. 4-FIG. 11 , the manufacturing method of an embodiment selected by the present invention is shown in the figure, which is for illustration only, and is not limited by this manufacturing method in patent application.

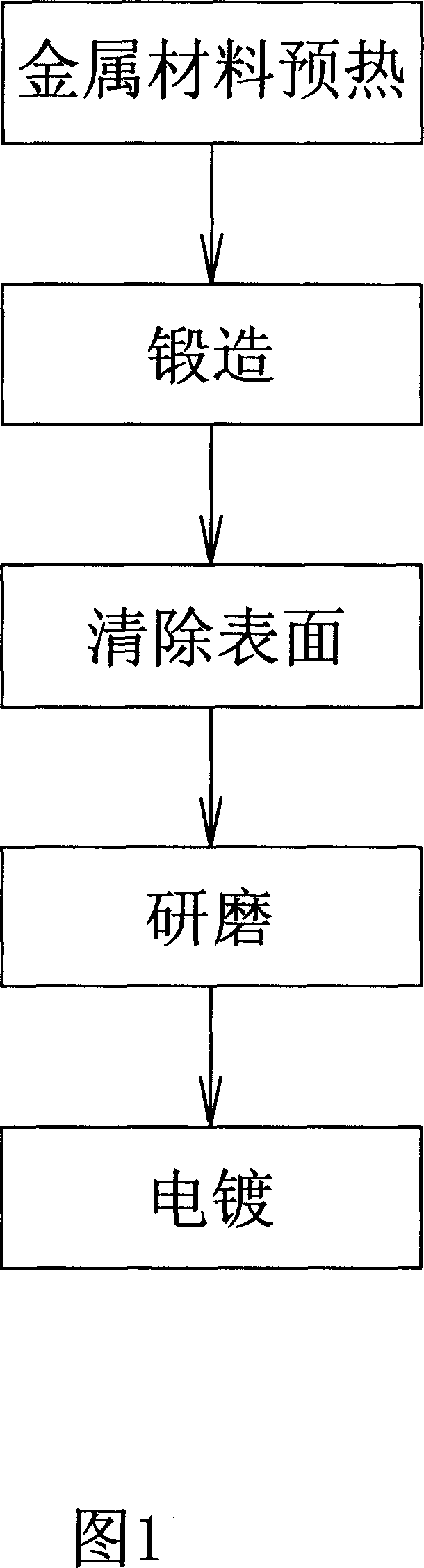

[0027] The present invention relates to a method for manufacturing a tool body, please refer to the simplified flow diagram shown in FIG. 4 . The manufacturing method of this tool body is mainly formed by combining four kinds of processing processes. In the manufacturing process, it can not only complete the processing very quickly, but also save a lot of time and material costs, and can greatly improve the tool body. Excellent texture and anti-skid performance. The processing technology of each program is the process of metal material preheating, forging and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com