Systems and methods for detecting undesirable operation of a turbine

A turbine and operating parameter technology, applied in the direction of control system, mechanical equipment, engine components, etc., can solve problems such as excessive wear of turbine components, thrust natural balance imbalance, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

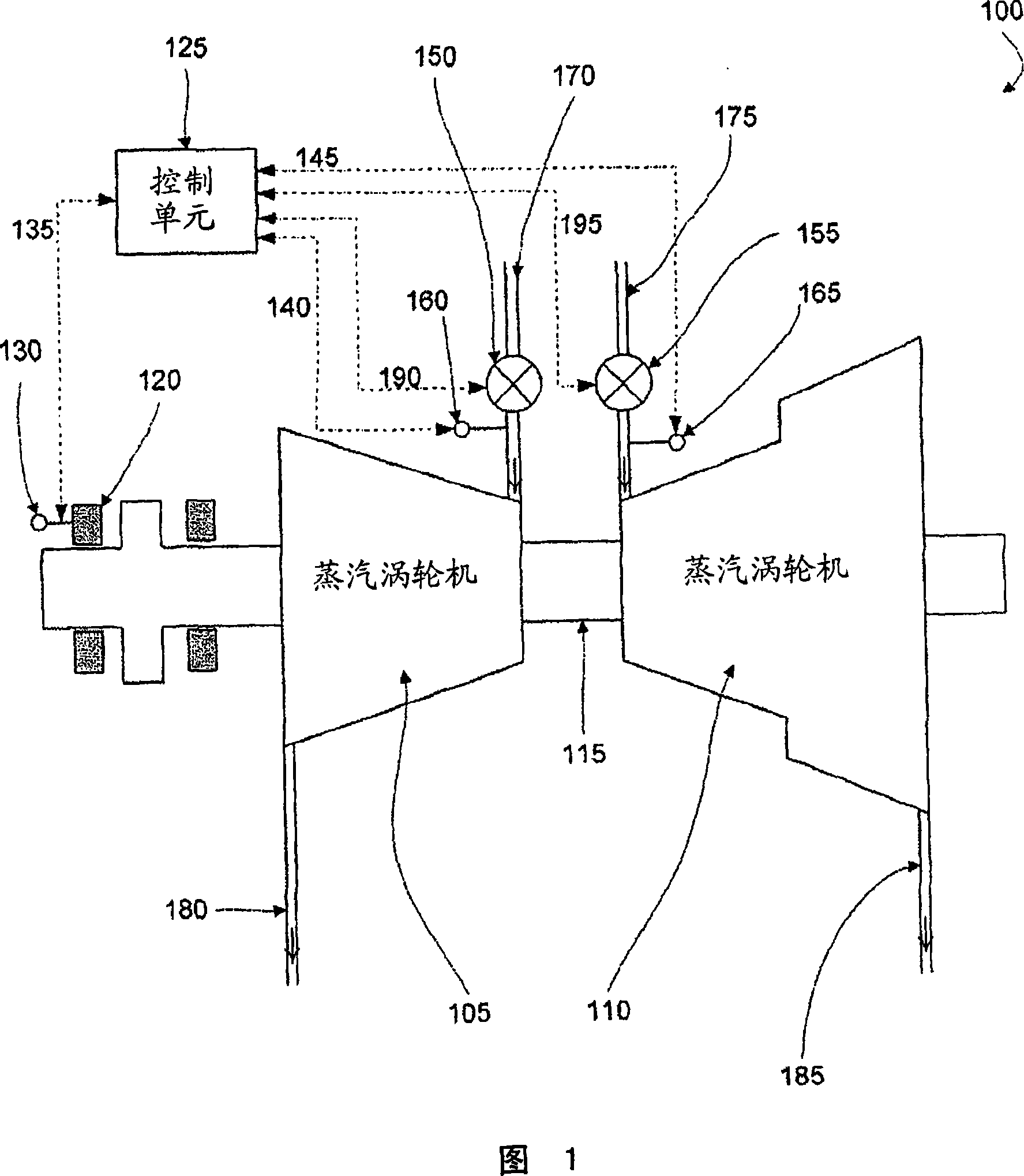

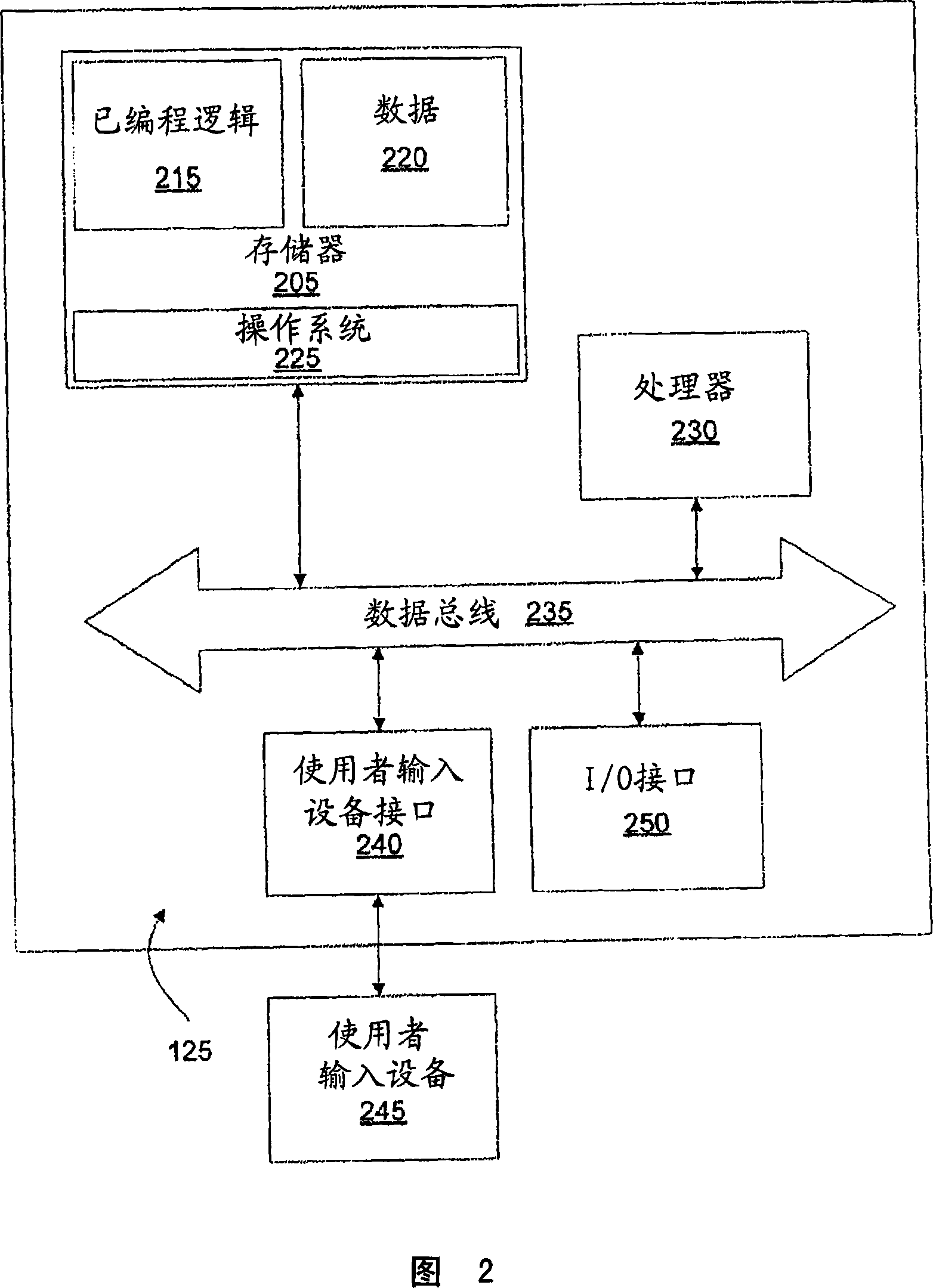

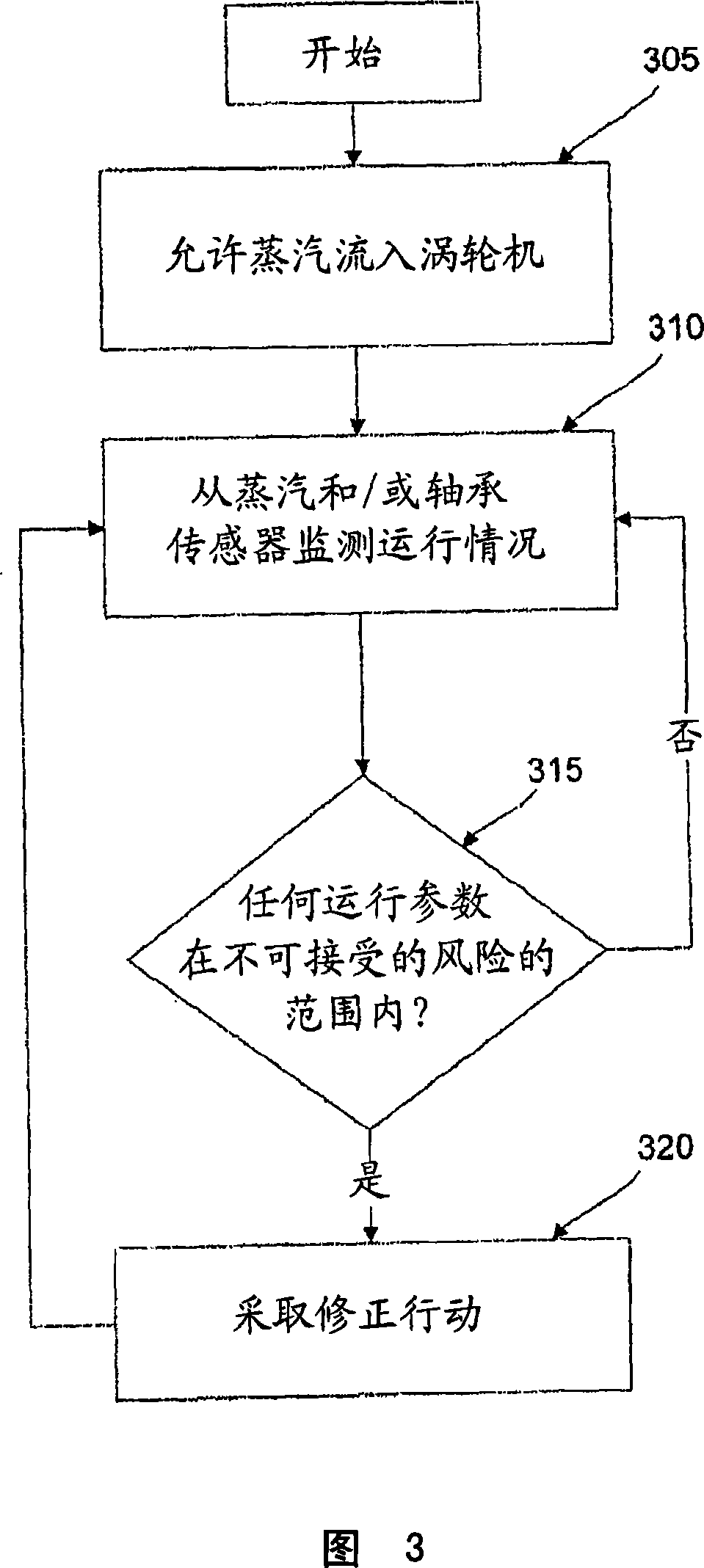

[0019] The present invention relates to systems and methods for utilizing measured operating parameters to determine if a turbine has entered an undesired region of operation. If undesired conditions exist, the turbine control system initiates corrective action to avoid damage to components. In an exemplary embodiment of the invention, steam pressure and bearing metal temperature sensors are used to monitor steam turbine operating conditions using a steam turbine control system programmed with steam turbine control system protection logic. Based on the information provided by the sensors, the steam turbine control system may initiate priority actions to prevent excessive wear or damage to steam turbine components that typically occurs when the steam turbine component(s) have exceeded their threshold limits. More specifically, the steam turbine control system will detect when the steam turbine enters an operating region of unacceptable risk (eg, an undesired flow imbalance oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com