Automatic saler

A vending machine and clapboard technology, applied to instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve misoperation, increase costs, increase man-hours for assembly, etc. problems, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. However, the present invention is not limited by these embodiments.

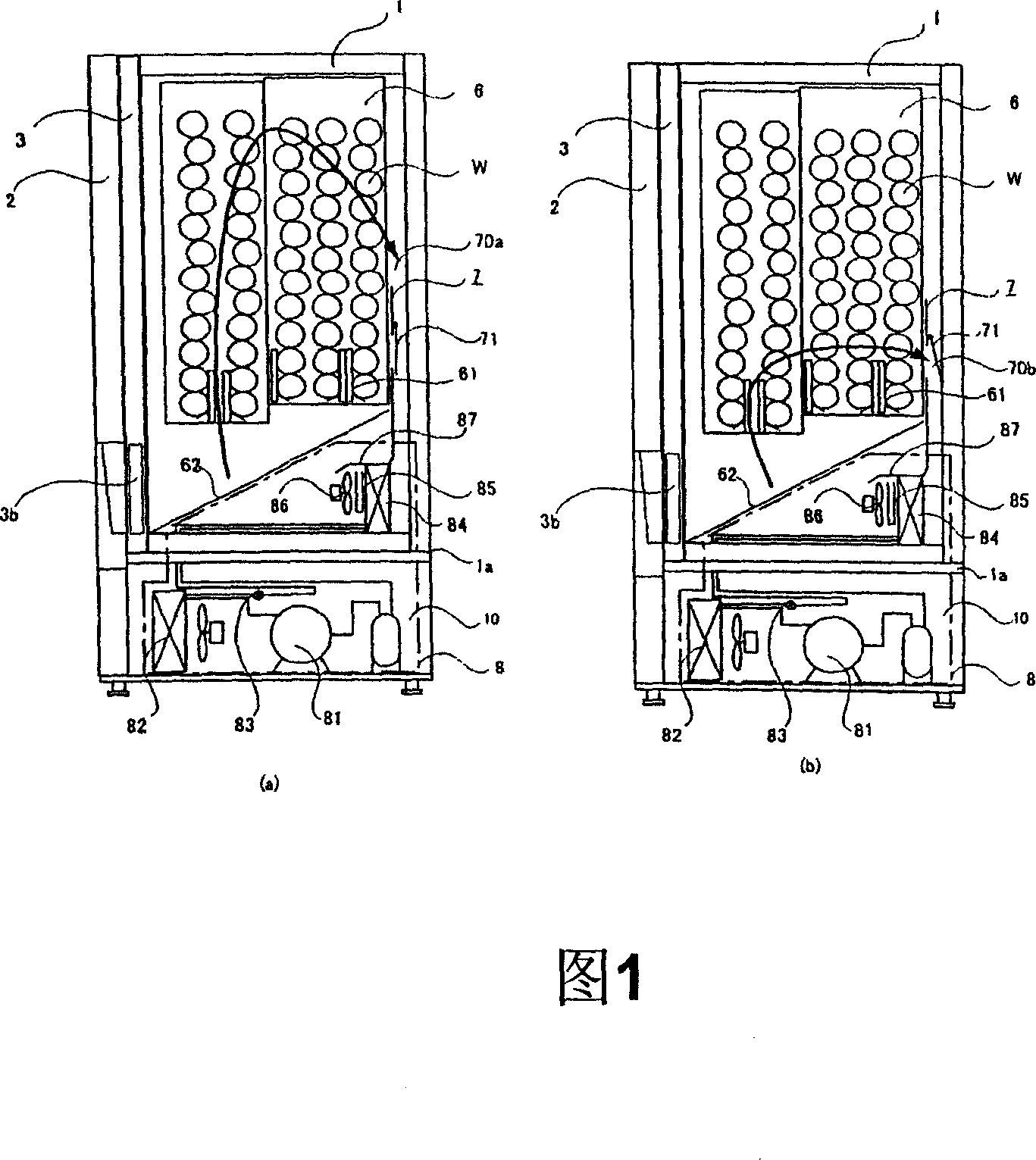

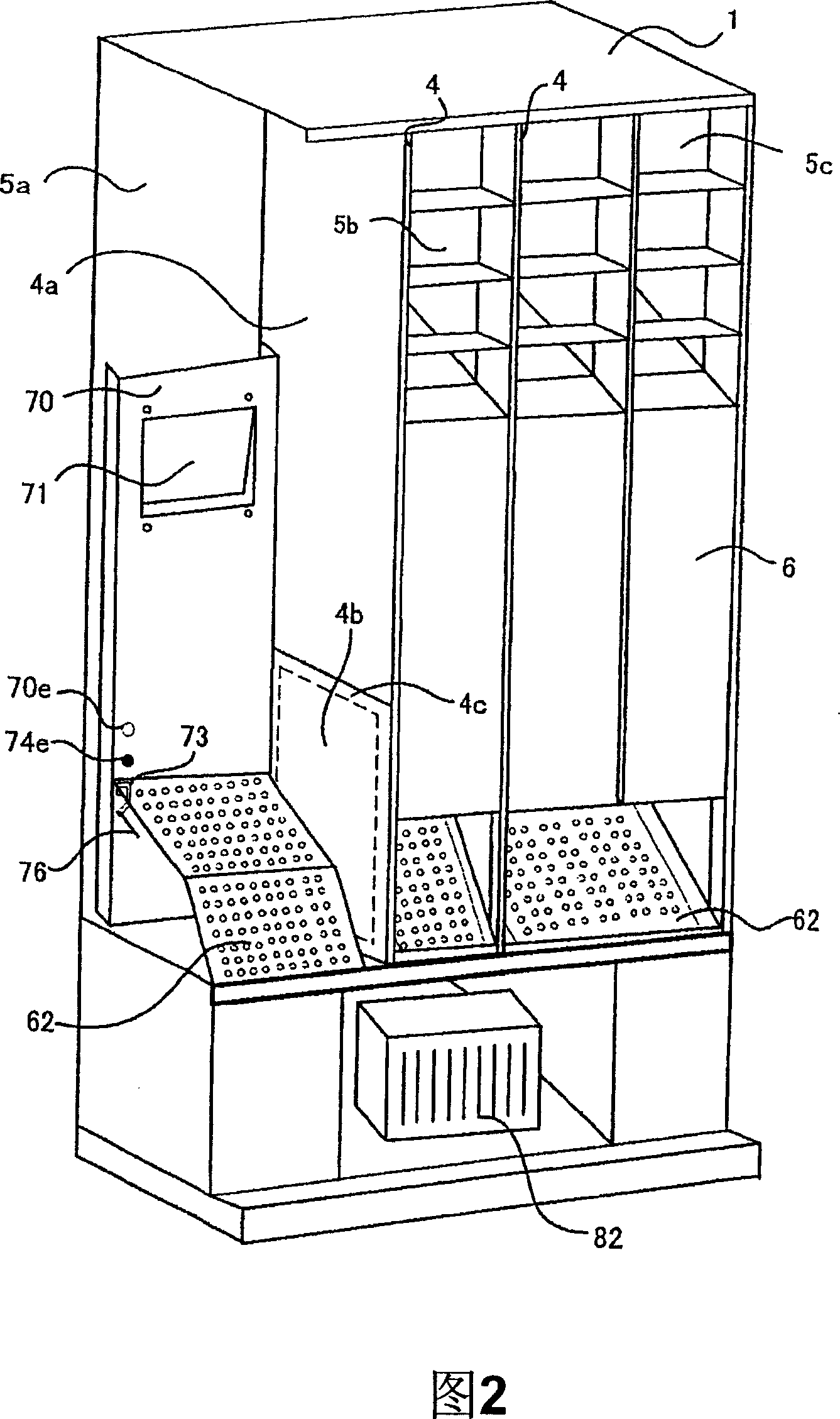

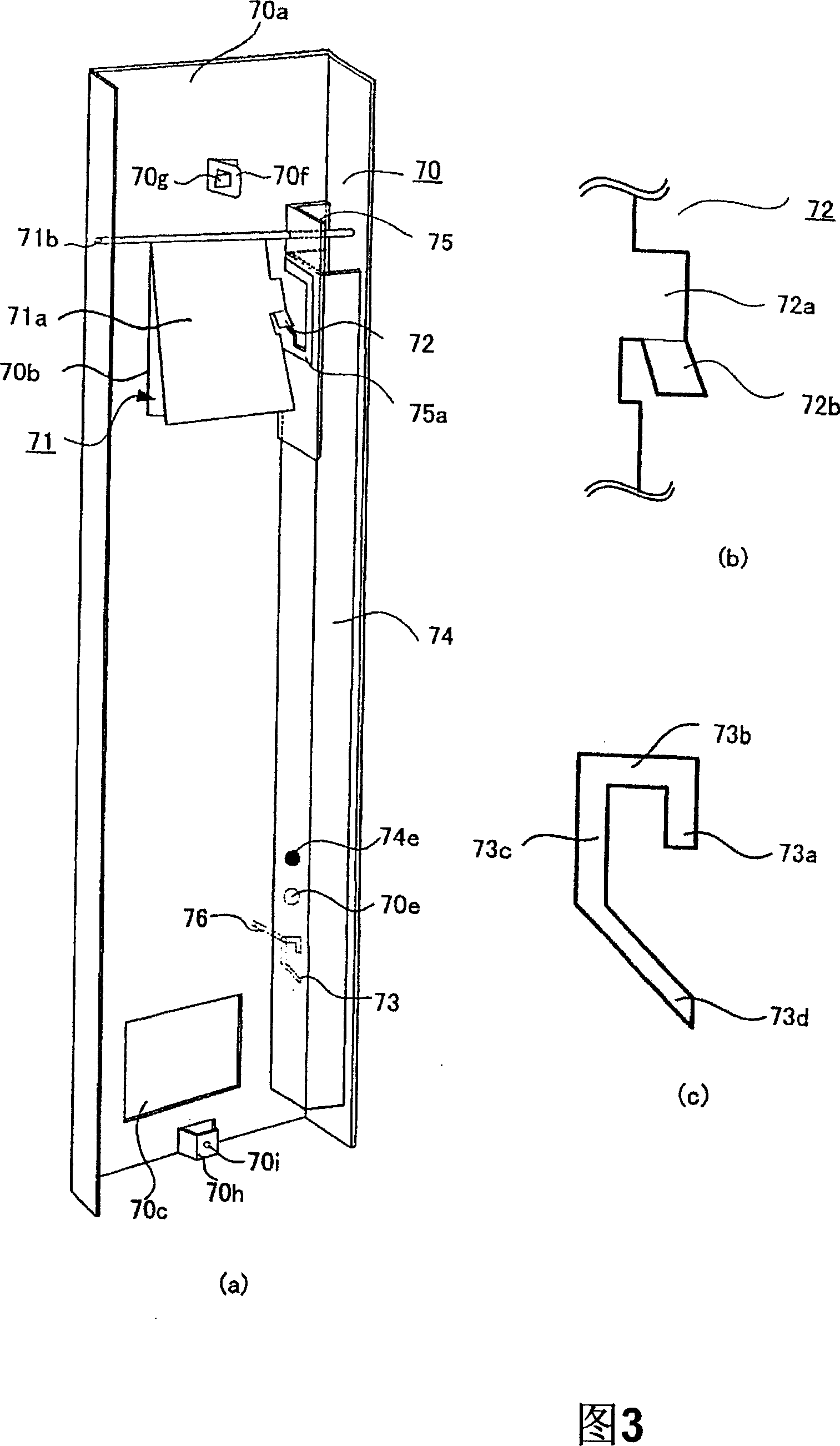

[0043] 1 to 5 are explanatory views showing the shape of the automatic vending machine according to the present invention. Fig. 1 is a side sectional view of an automatic vending machine, (a) showing a state in which the passage partition is closed, and (b) showing a state in which the passage partition is opened. Fig. 2 is a perspective view of a partial section of the vending machine. 3 is a structural view of the channel, (a) is a perspective view viewed from the inside of the channel; (b) is an enlarged view of the locking claw of the partition; (c) is an enlarged view of the guide groove. Fig. 4 is an operation diagram of the partition, a link and a lever when the partition is opened and closed, and Fig. 5 is an operation diagram of the locking claw and the locking groove of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com