Method for forming injection packaging paper box

A molding method and injection technology, applied in packaging, transportation and packaging, papermaking, etc., can solve the problems of reduced production efficiency, high production cost, waste of paper, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

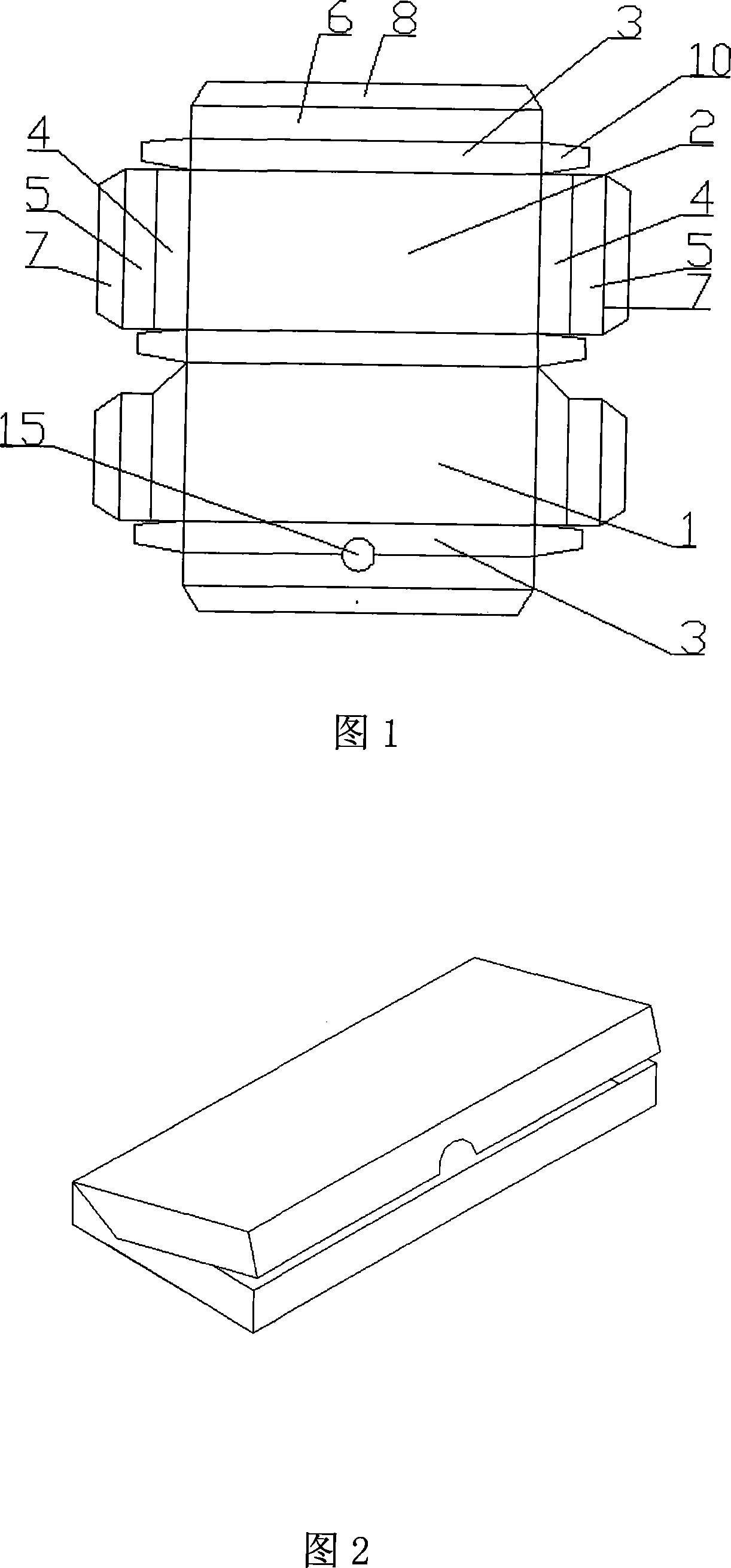

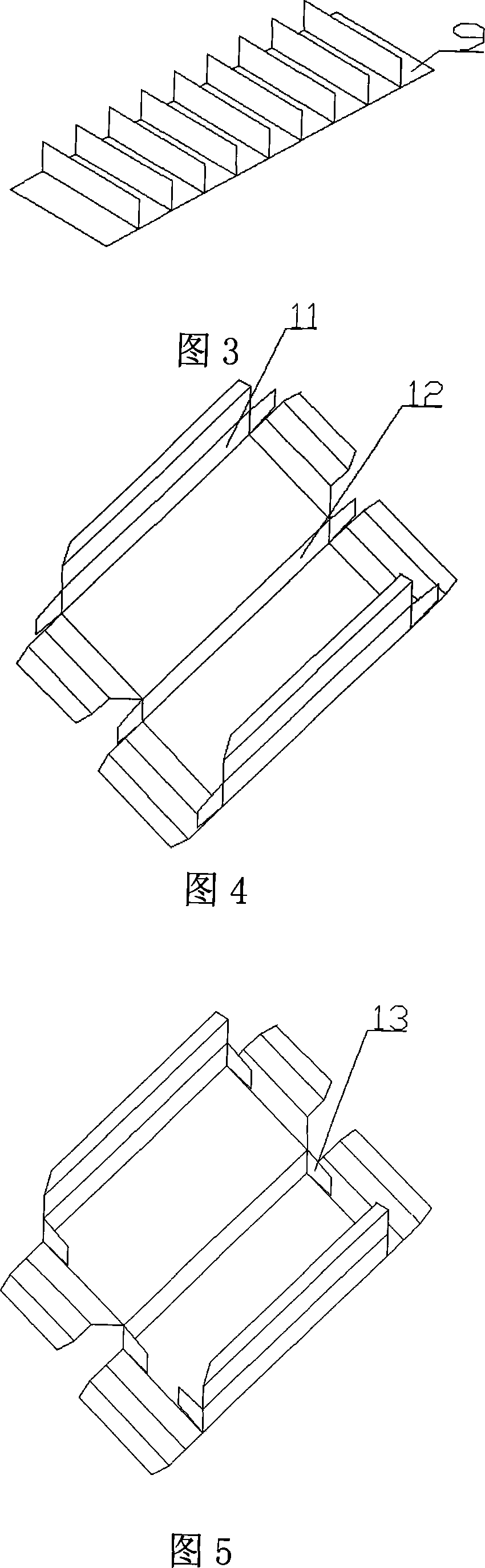

[0023] As shown in Figure 1, it is made of only one slab (the slab is the plan view of the injection packaging carton), including: the main surface 1 of the box and the bottom surface 2 of the box in the middle, between one side of the two It is the outer end surface 3, the left and right ends of the box main surface 1 and the box bottom surface 2 are the outer surface 4, the middle side 5 and the inner surface 7 respectively, and the other side of the box main surface 1 and the box bottom surface 2 are respectively the outer end surface 3, The middle end surface 6, the inner end surface 8, and the length of the two ends of the outer end surface 3 are greater than the lengths of the main surface 1 of the box and the bottom surface 2 of the box in the same direction to form tension surfaces 10 at both ends; Creases or eyelets for easy bending.

[0024] Its molding steps are:

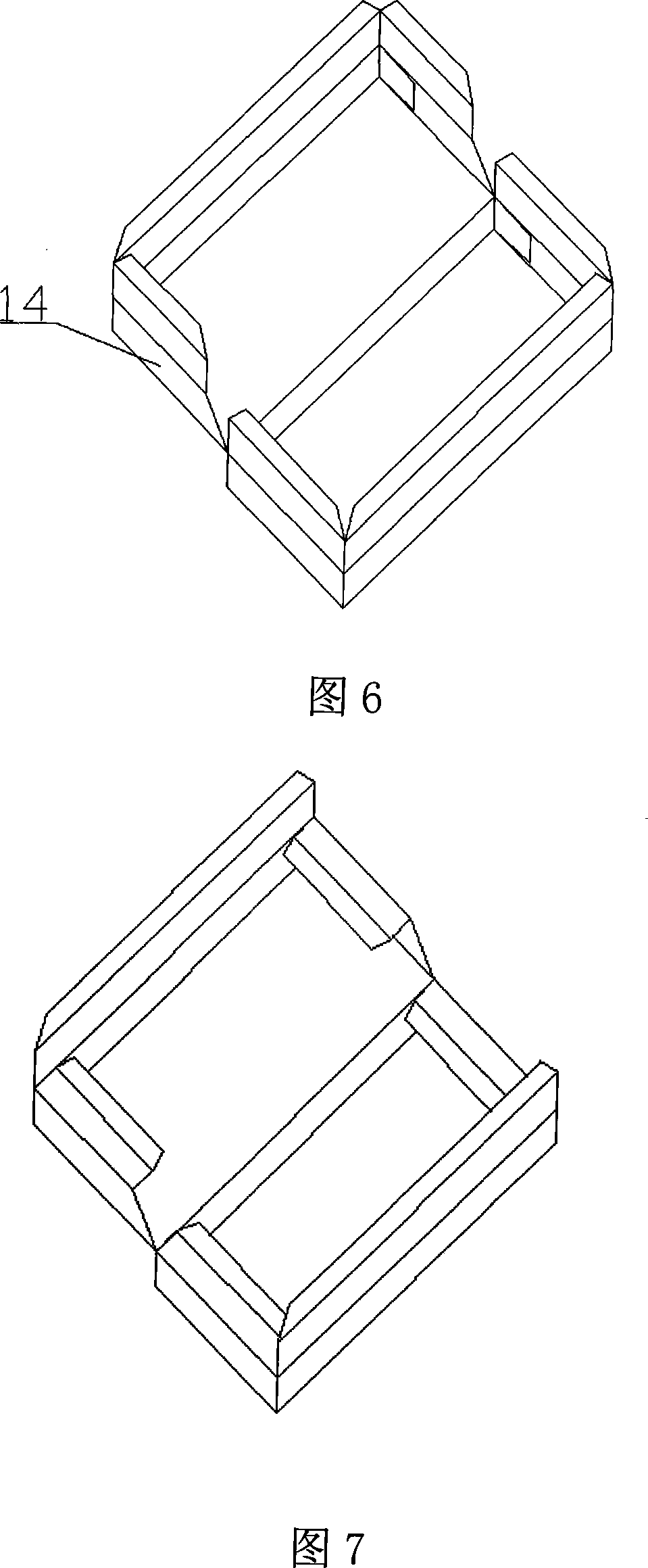

[0025] 1. Fold the front wall 11 and the rear wall 12 according to the shape of the outer end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com