Door construction for a lift

A technology for elevators and door leaves, which is applied to elevators, door/window accessories, building structures, etc. in buildings, and can solve the problems of high technology costs and very high requirements for guide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

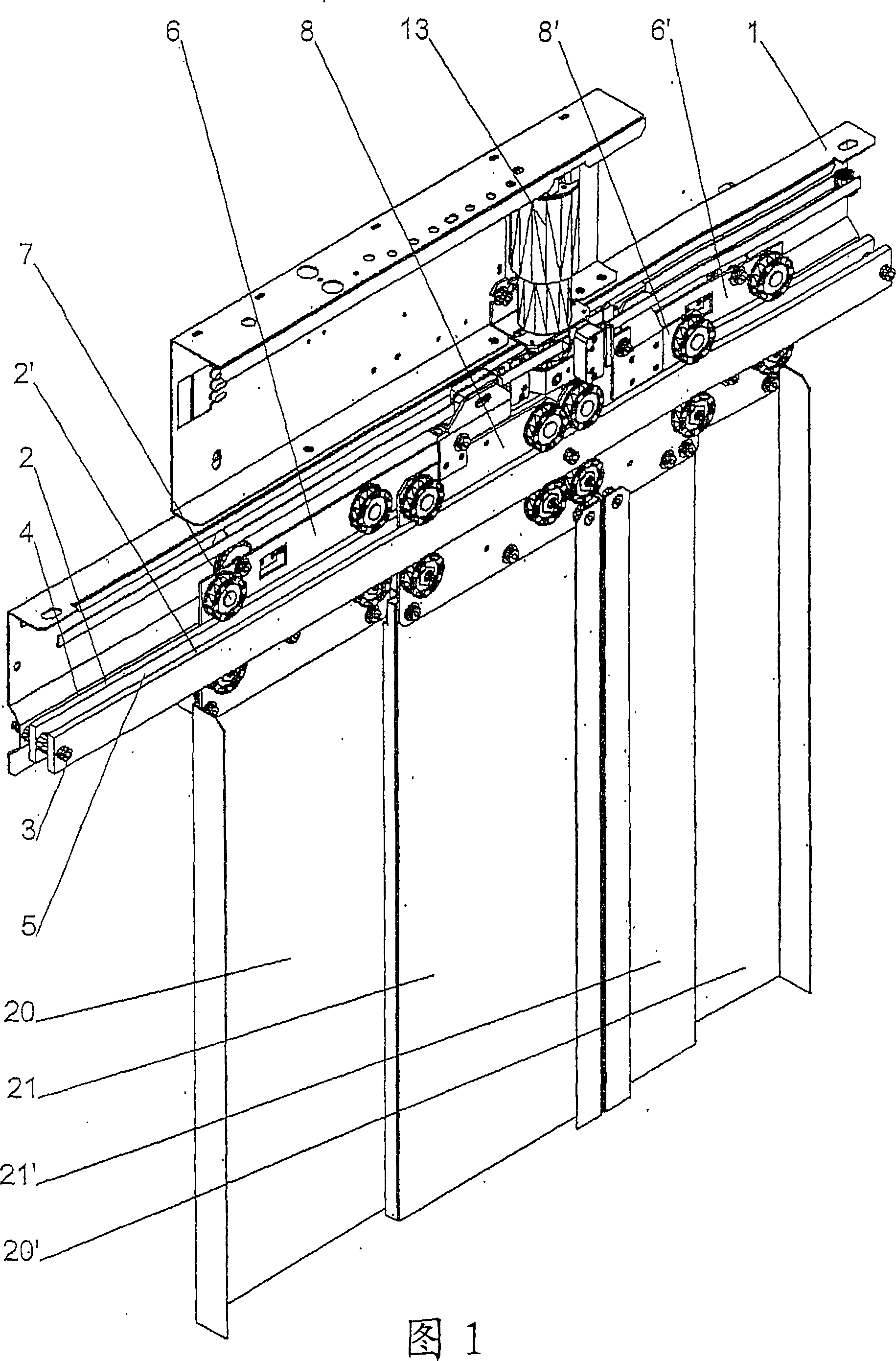

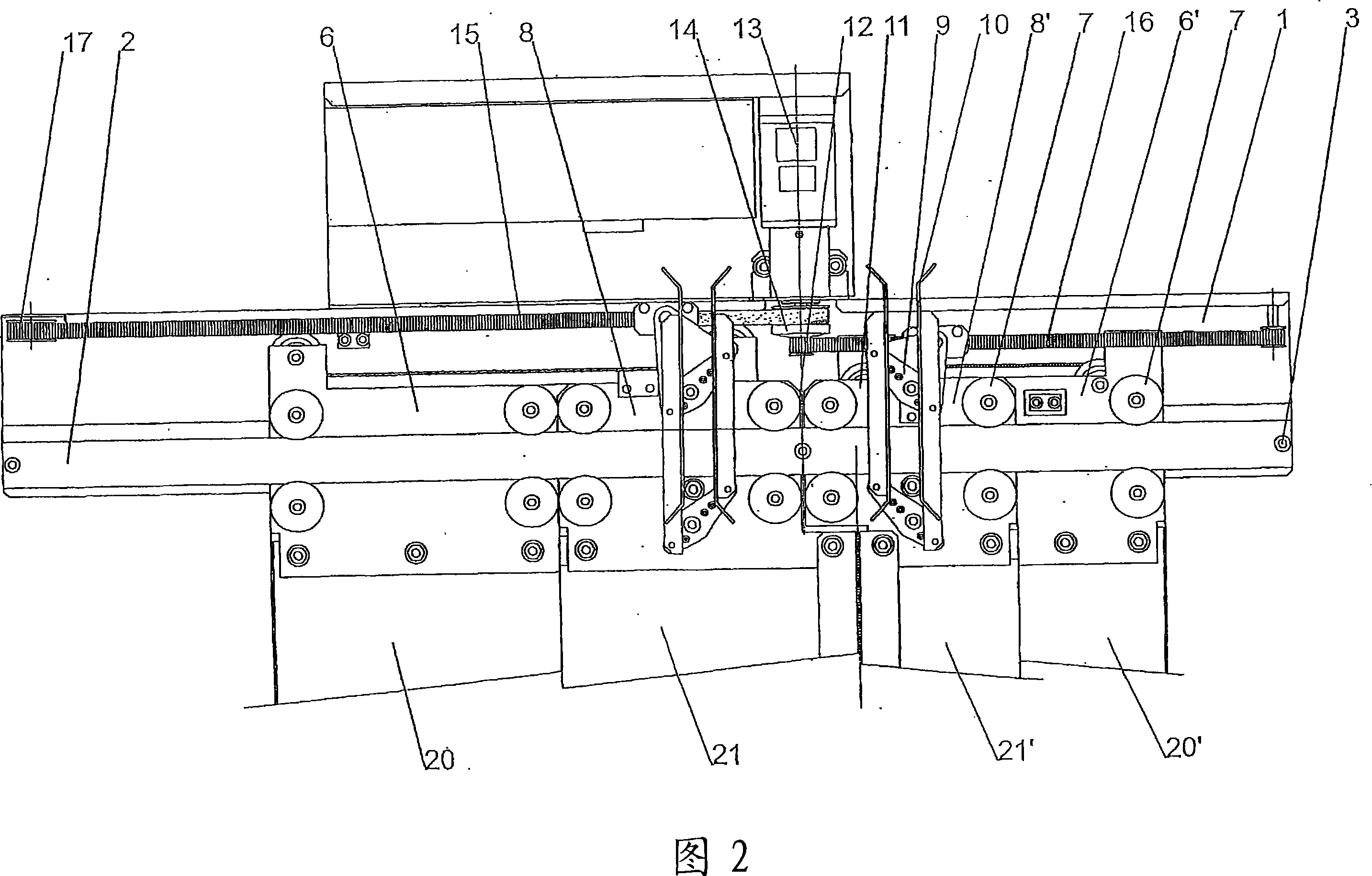

[0013] The invention is described in connection with elevator car doors, but the invention can also be used for elevator hoistway doors. Two groups of door leaves are provided, wherein one group includes two left door leaves 20, 21 (as shown in Figure 2), and the other group includes two right side door leaves 20', 21' (as shown in Figure 2). One group of door leaves 20,21 are opened towards the left (seeing figure 2), and the door leaves 20', 21' of another group are opened towards the right (seeing figure 2). Within a group, the two leaves 20, 21 or 20', 21' slide in a relatively telescopic manner when opened. The right leaf 20', 21' is narrower than the left leaf 20, 21.

[0014] On the door beam 1 mounted on the elevator car, not further shown, two guide rails 2, 2' are fixed. At this time, the two guide rails 2, 2' are parallel to each other and extend along the horizontal direction. The guide rails 2, 2' are held in place by the bolts 3, which here also define the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com