Closed loop fluid dispensing system

一种流体分配、圈体的技术,应用在液体分配、分配装置、液体分配、输送或转送装置等方向,能够解决不可能实现、很难制造出、取下去除或剥离困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

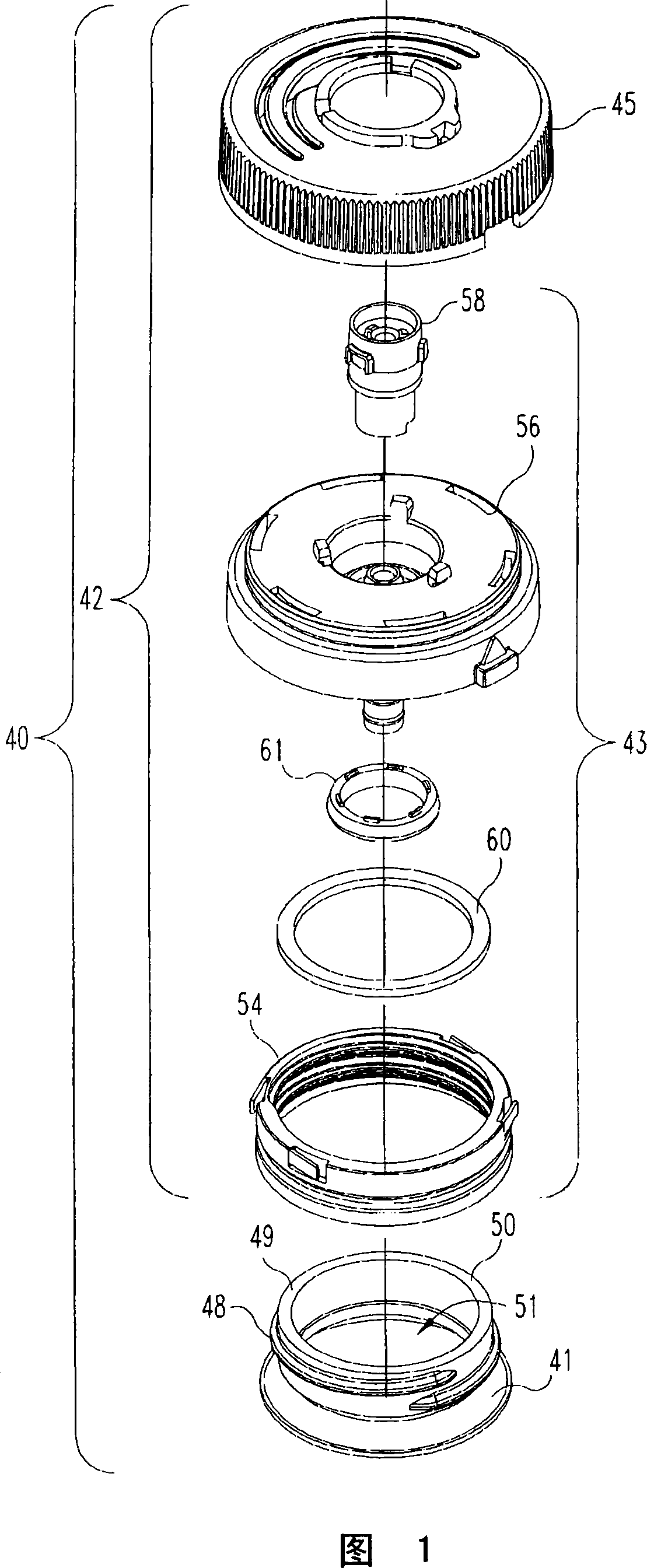

[0055] To facilitate an understanding of the principles of the invention, reference will now be made to the embodiments shown in the drawings, and specific language will be used to describe the embodiments. It should be understood, however, that this is not a limitation of the scope of the invention. Any changes and further modifications of the described embodiments, and other applications of the inventive principles presented herein will occur to those skilled in the art. An embodiment of the invention has been shown in great detail, although it will be obvious to a person skilled in the art that some features which are not relevant to the invention may not be shown for the sake of clarity. It should be noted that directional terms (such as "upper," "upper," "lower," "downward," "top," and "bottom") are used herein for the convenience of the reader only to help the reader understand the illustrated implementation. For example, it is not intended that the use of these directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com