Cage for coke guide car

A coke-guiding vehicle and cage technology, which is applied in the field of improvement of the coke-guiding vehicle cage, can solve problems such as overcrowding, and achieve the effect of smooth forward and backward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

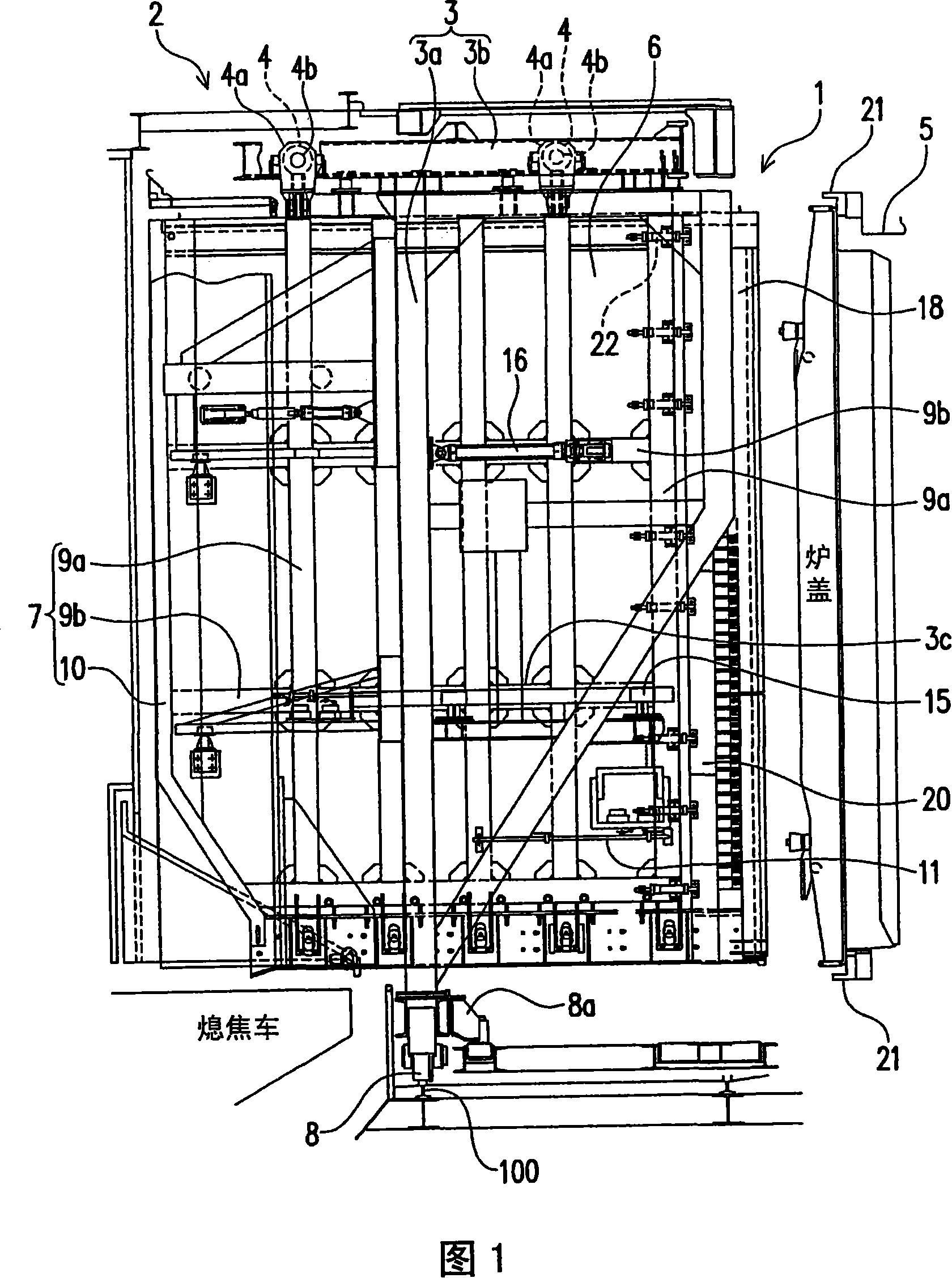

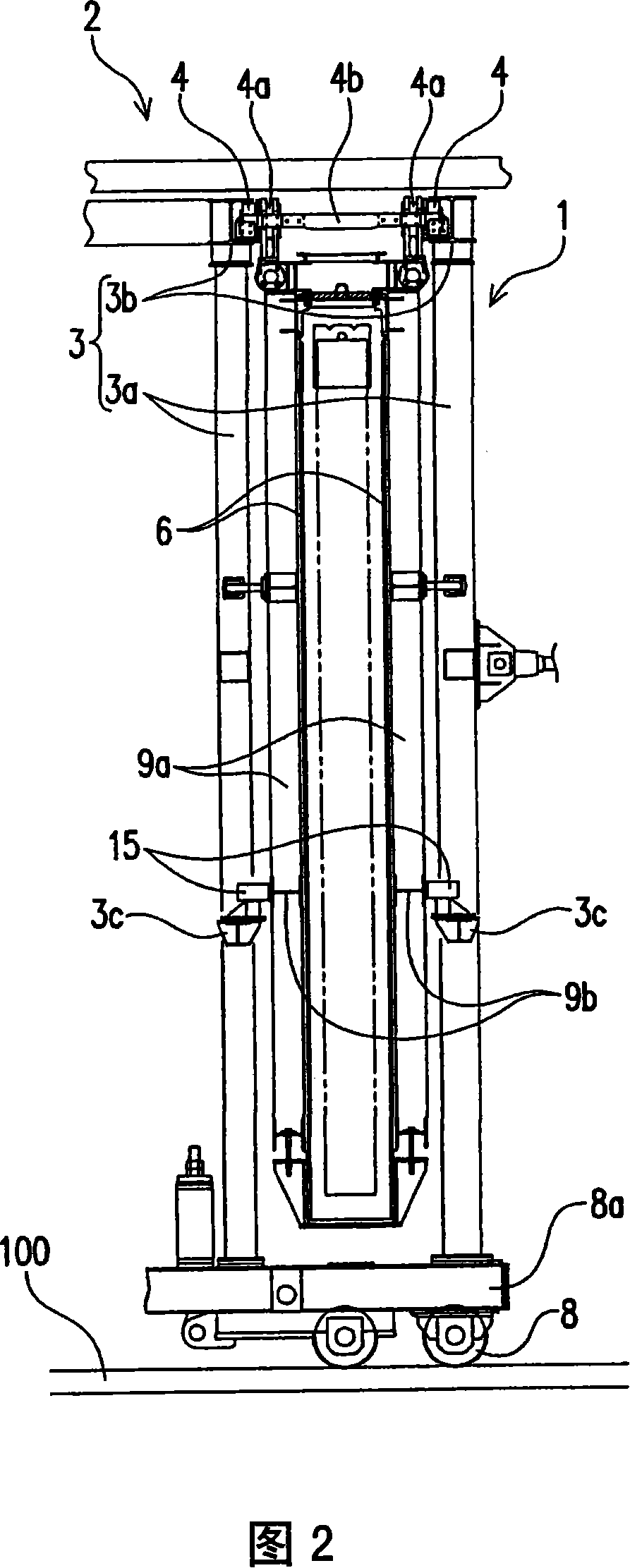

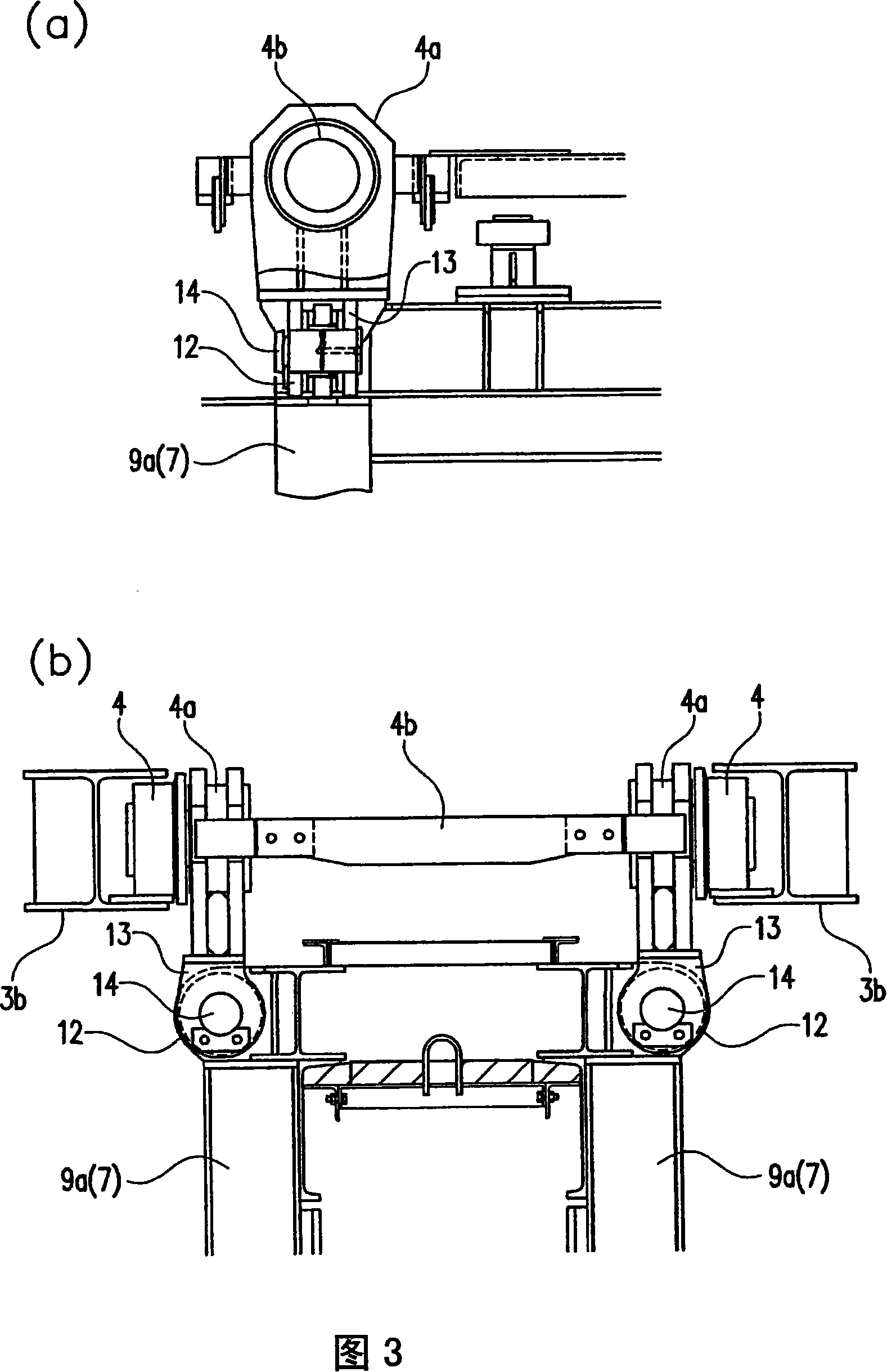

[0030] Next, an embodiment of the cage for a coke guiding vehicle according to the present invention will be described with reference to the drawings. Fig. 1 is a right side view showing a cage for a coke guiding vehicle according to an embodiment of the present invention, and Fig. 2 is a front view (viewed from the carbonization chamber side) of the cage for a coke guiding vehicle according to an embodiment of the present invention. As shown in Fig. 1 and Fig. 2, the cage 1 for the coke guiding vehicle is supported on the frame 3 of the coke guiding vehicle 2 via the suspension wheels 4, and the cage 1 is formed by arranging a plurality of carbonization chambers 5... Each carbonization chamber 5 of the coke oven can move forward and backward freely. In addition, in the present embodiment, the coke guiding vehicle 2 is disposed so as to be able to move forward and backward freely on the rail 100 laid in the parallel direction of the plurality of coking chambers 5 . . . via the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com