Calcining system for nickel-iron alloy production

A nickel-iron alloy and calcination technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of stamping only one product, difficulty in taking out, etc., and achieve the effects of improving stability, moving smoothly, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

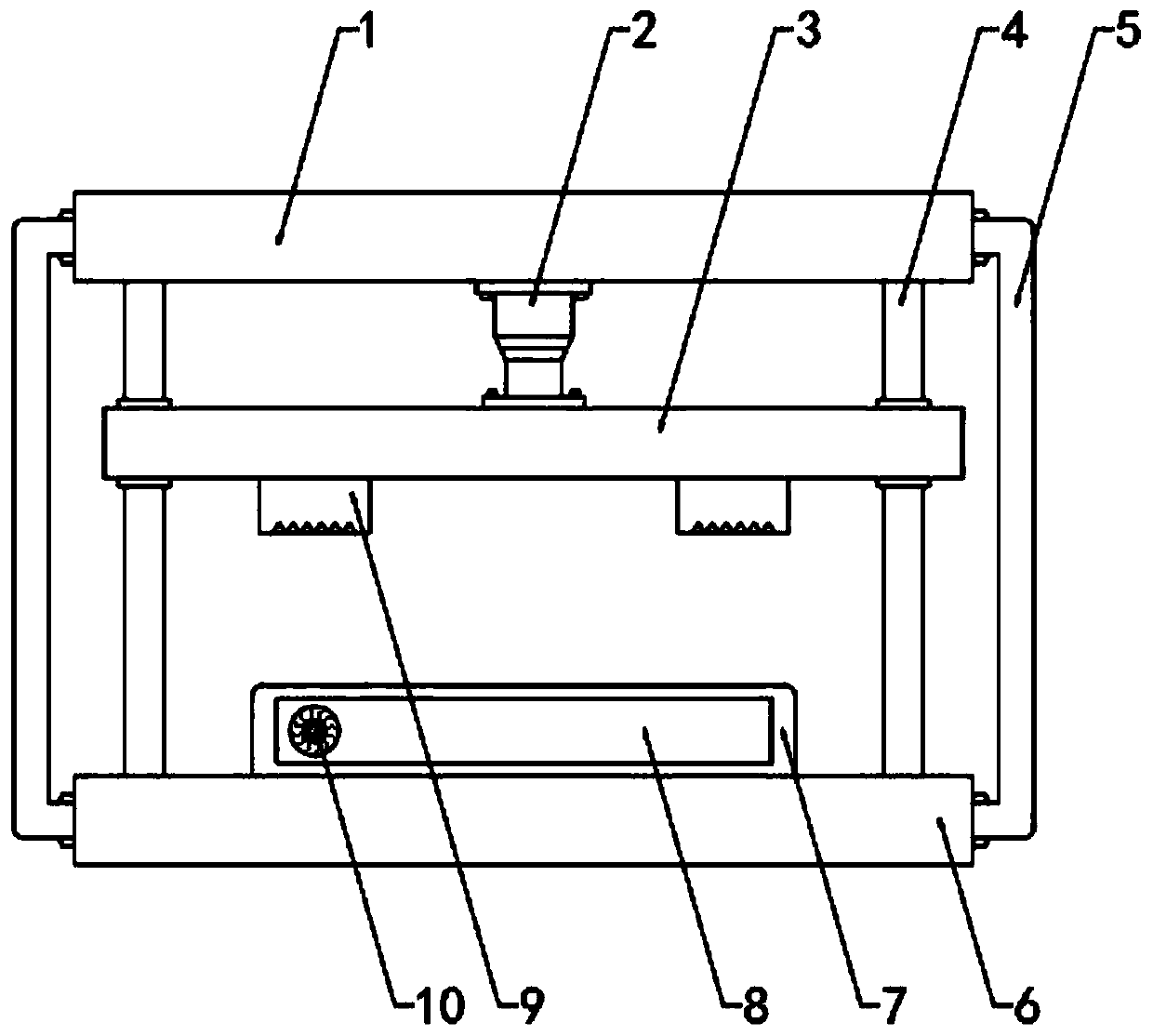

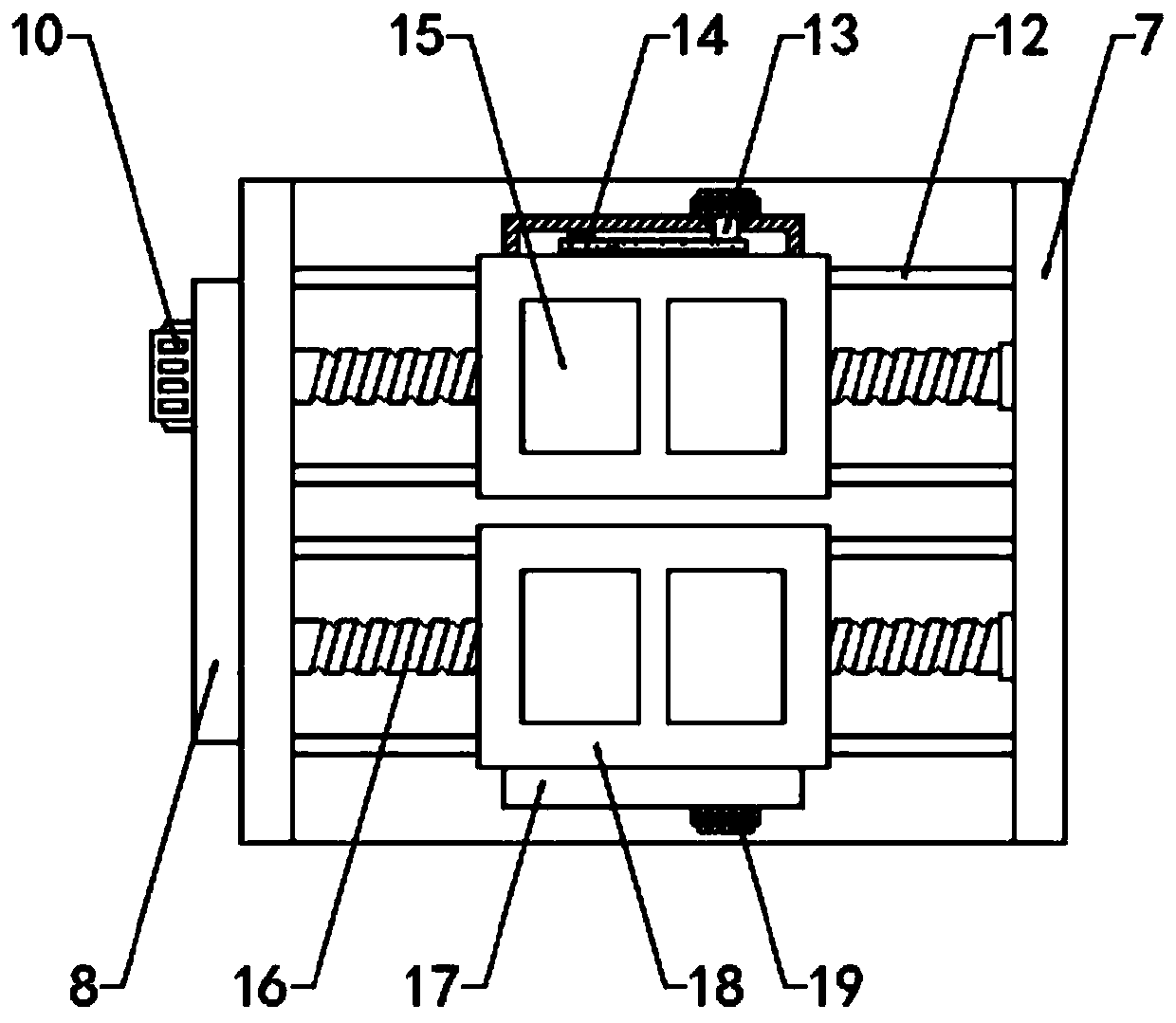

[0035] see Figure 1-5 , a calcination system for nickel-iron alloy production, comprising a top plate 1, a bottom plate 6 and a support 5, the support 5 is fixed between the top plate 1 and the bottom plate 6, the bottom of the top plate 1 is provided with a moving plate 3 and the lower surface wall of the moving plate 3 is fixed There are two dies 9, a cylinder 2 is arranged between the moving plate 3 and the top plate 1, one end of the cylinder 2 is fixed on the lower surface wall of the top plate 1, the other end is fixed on the upper surface wall of the moving plate 3, and the upper surface wall of the bottom plate 6 Fixed frame 7 is fixed, and the inside of fixed frame 7 is provided with two longitudinally distributed threaded rods 16, and the inner wall of threaded rod 16 and fixed frame 7 is for rotation fit, and the exterior of two threaded rods 16 is screwed with lower mold base 18, The side wall of fixed frame 7 is fixed with the first driving mechanism that drives ...

Embodiment 2

[0038] see figure 1 , there are two guide rods 4 symmetrically running through the moving plate 3, the vertical ends of the guide rods 4 are respectively fixed with the top plate 1 and the bottom plate 6, the moving plate 3 and the guide rods 4 are slidingly fitted, which can prevent the moving plate 3 from moving vertically. The offset occurs during the movement in the direction, which improves the stability of the device.

[0039] The difference from Example 1 is that

Embodiment 3

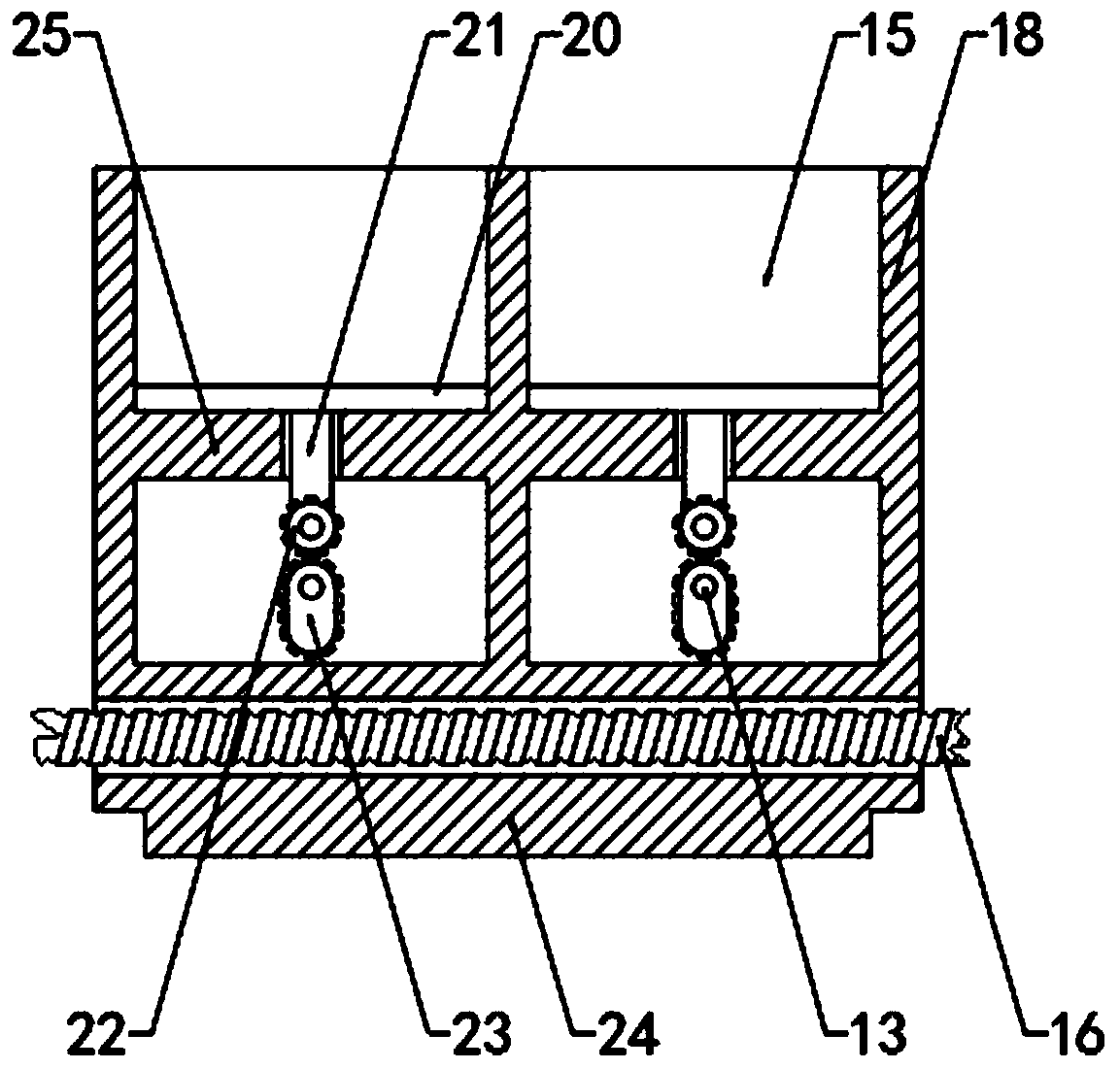

[0041] see image 3 and Figure 5 , the second drive mechanism includes a transmission shaft 13 arranged at the bottom of the placing table 25, the second gear 23 is sleeved on the outside of the transmission shaft 13, the vertical ends of the second gear 23 are semicircular, the middle is rectangular, and the second The gear 23 and the transmission shaft 13 are eccentrically arranged. The lower surface wall of the push plate 20 is fixed with a push rod 21. The push rod 21 runs through the placement table 25 and is provided with a first gear 22. The first gear 22 and the push rod 21 are in rotation. The first gear 22 is engaged with the second gear 23, and the side wall of the lower mold base 18 is fixed with a second fixed cover 17, and the transmission shaft 13 penetrates into the inner cavity of the second fixed cover 17 and is connected by the second belt 14. The second motor 19 for driving the transmission shaft 13 is fixed on the side wall of the second fixed cover 17 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com