Automatic sewage cleaning system for pig farm

An automatic cleaning and pig farm technology, applied in the field of animal husbandry, can solve the problems of staying on the leaking manure board, poor working environment, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

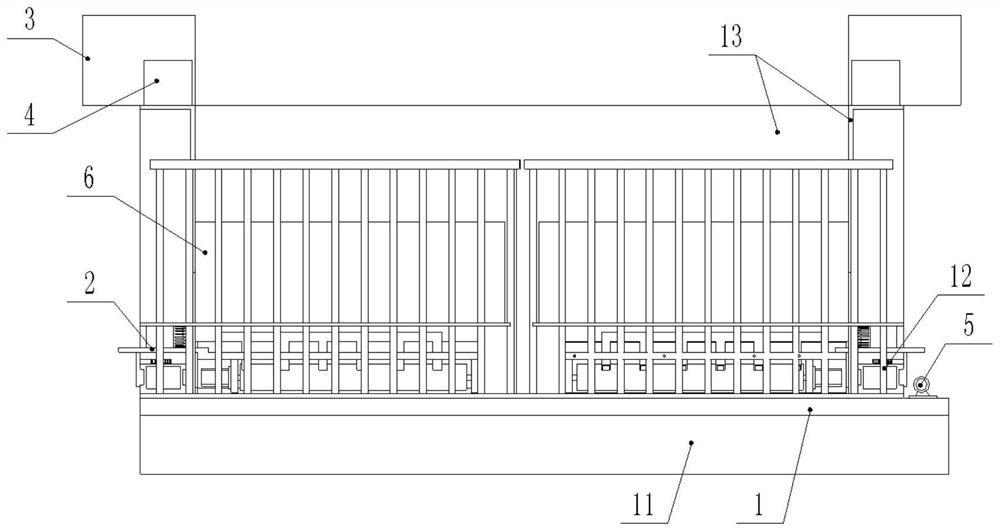

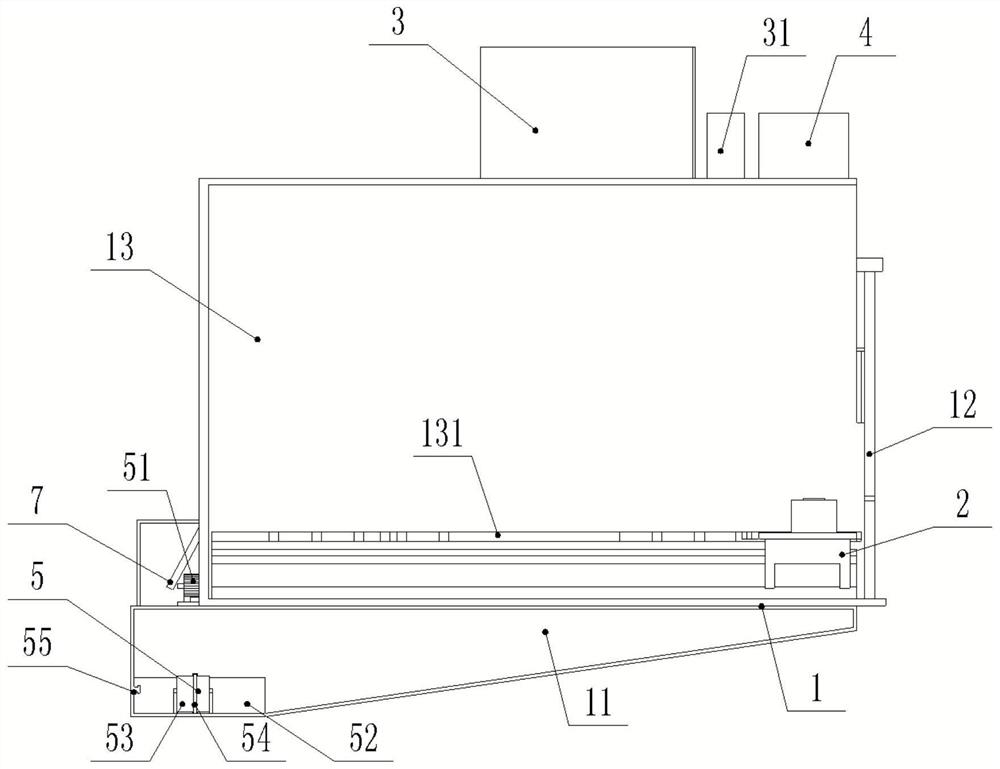

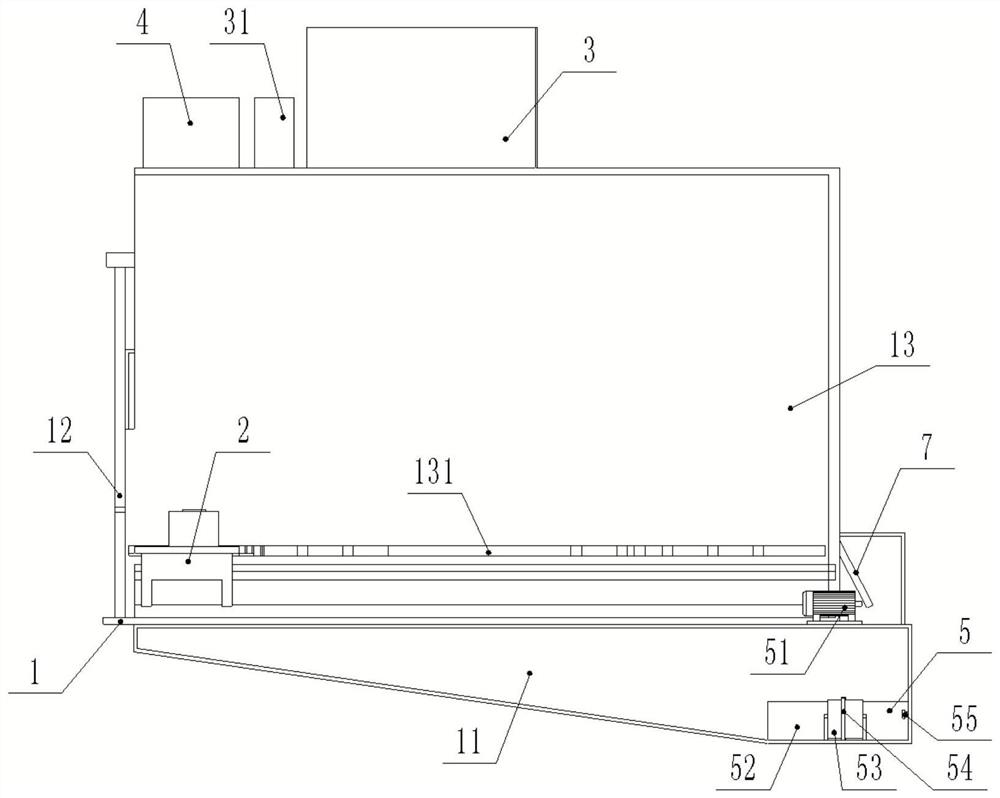

[0043] The present invention is an automatic decontamination system for pig farms, which includes a breeding space surrounded by a fence 12 above a bearing surface 1 and a surrounding wall 13. The bearing surface 1 is made of ordinary plastic material and has a good thermal insulation coefficient, and It does not absorb water, and the lower part of the bearing surface 1 is the manure channel 11. The bearing surface 1 is provided with dense leak holes 14 to form a manure leakage board. Pig urine and thinner manure can leak through the leak holes 14 and enter the manure. In the sewage channel 11, the breeding space is divided into two symmetrical rooms and is communicated through the fence door 121, such as Figure 5 , 6 As shown, when performing automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com