Fully-mechanized mining equipment optimizing configuration method

A technology for optimizing configuration and fully mechanized mining equipment, applied in the direction of instruments, data processing applications, forecasting, etc., can solve problems such as inability to evaluate economically and technically, and achieve the effect of optimal configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the method for optimizing the configuration of fully mechanized mining equipment proposed by the present invention, at first, the basic information of the equipment is input into the optimal configuration system of fully mechanized mining equipment of the present invention, the basic information of the equipment includes: technical characteristic parameters, production parameters, and Operation and management parameters including maintenance and repair fees, one-time overhaul fees, etc. Then, the fully mechanized mining equipment optimal configuration system obtains the evaluation data of each parameter of the equipment according to the basic information of the equipment, and comprehensively evaluates each parameter of the equipment according to the obtained evaluation data of each parameter.

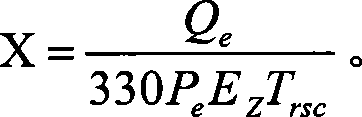

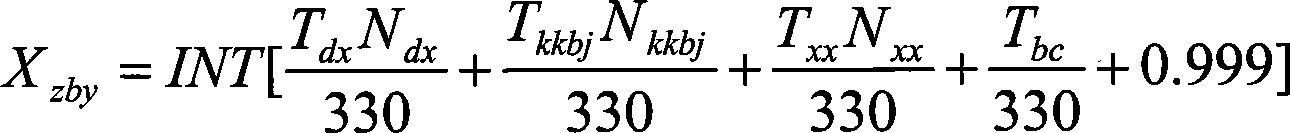

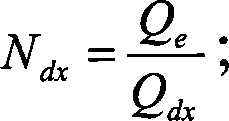

[0028] Total amount of fully mechanized mining face equipment X z1 Equal to the number of operating equipment X and the number of spares in the fully mechanized mining face z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com