Device for orienting flat items of mail towards a narrow edge

A technology for mail and equipment, which is applied in the field of equipment aligned with a narrow side, and can solve problems such as alignment and conveying interference, mail damage and reading, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

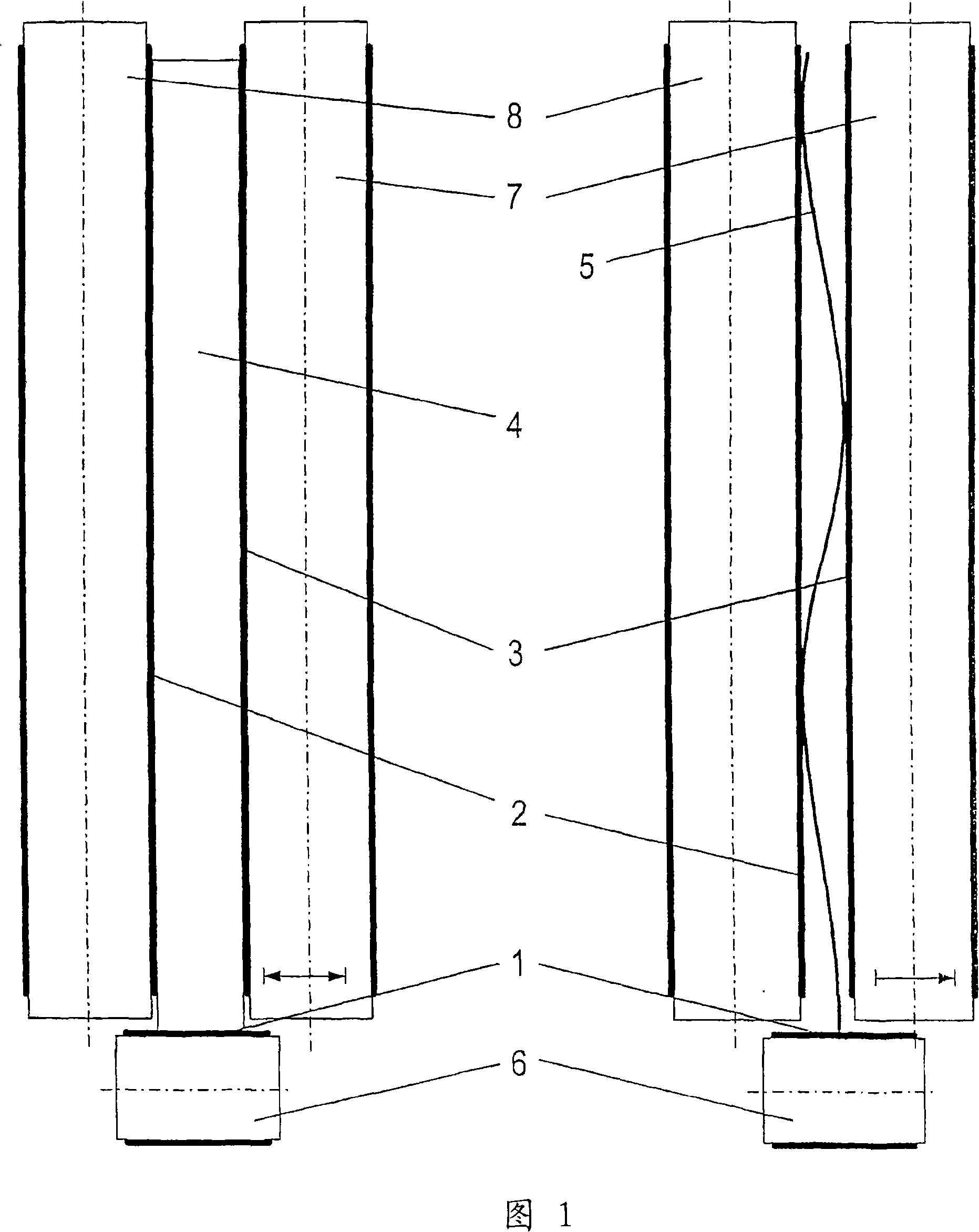

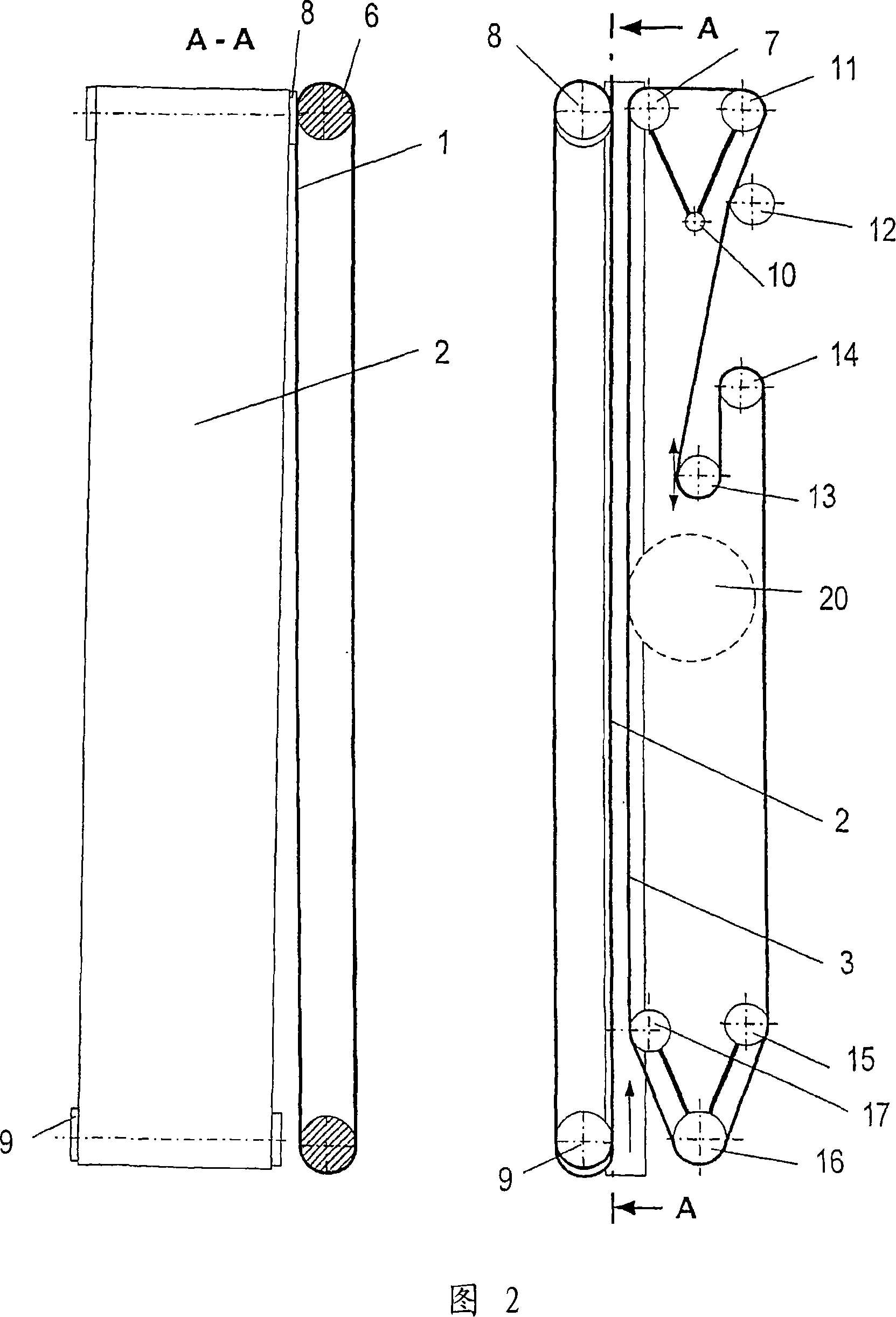

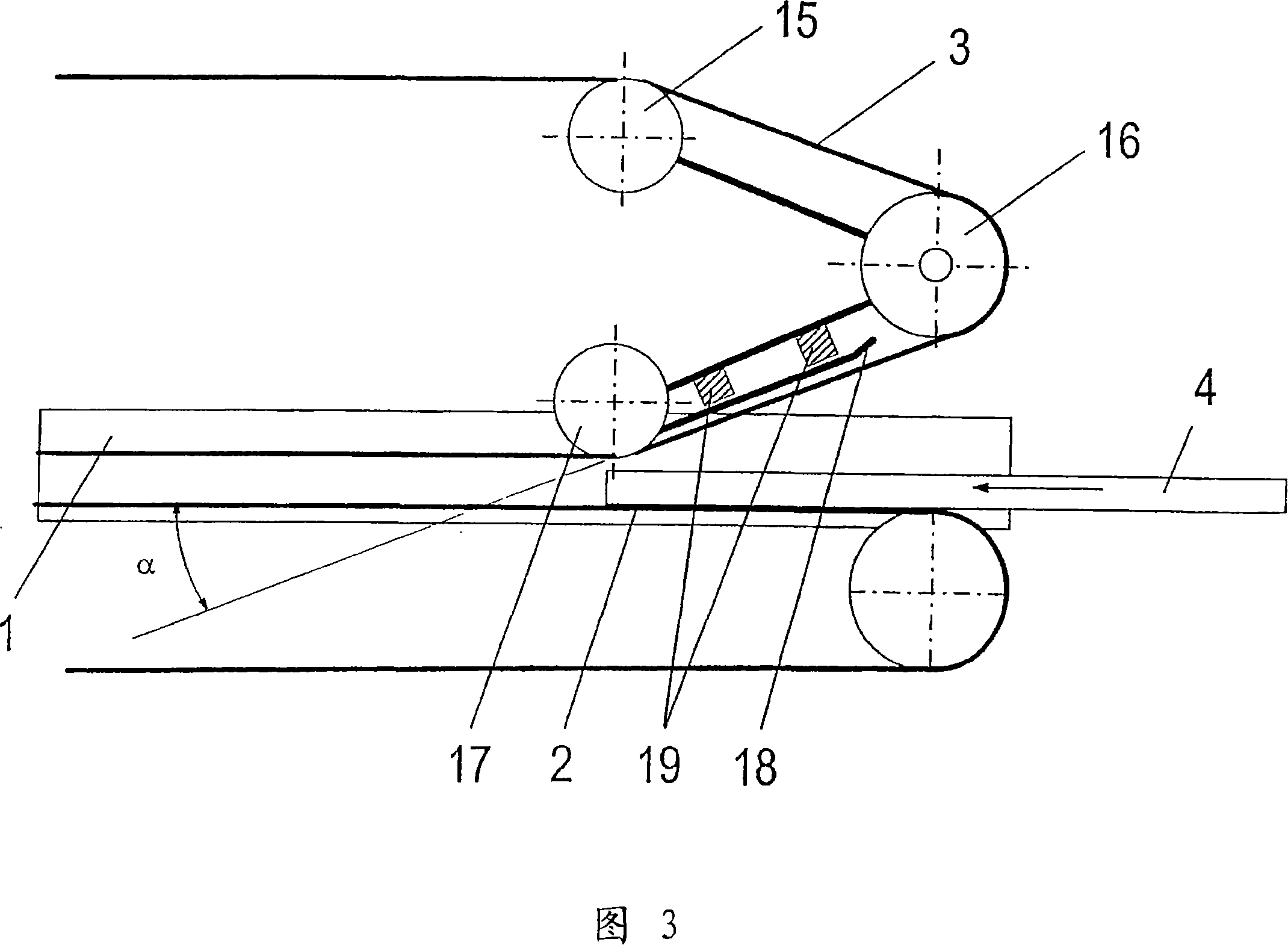

[0023] As shown in Figure 1, the alignment device consists of a horizontally oriented endless base belt 1 with a driven, guided by a turn roller 6 and two vertically oriented endless belts driven at the same speed. Side guide belt 2,3 is formed. In this case, a guide belt 2 as a reference side web is guided by stationary guide rollers 8 , 9 , wherein the guide rollers 8 , 9 are oriented such that the reference side web 2 is inclined in the conveying direction. The other guide strip 3 has a defined minimum distance from the reference side strip 2 when the conveying path is empty, which ensures that thin, curled loose mail items 5 are not jammed or folded. The other guide belt 3 is arranged at the infeed and outfeed by a specific oscillating combination (Schwingenkombination) 7, 10, 11 and 15, 16, 17 in such a way that the thick The mail piece 4 is deflected passively and thus orientated on the second guide belt 2 . The length of the alignment device and the selected gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com