Cutting equipment for processing stainless steel products

A cutting equipment, stainless steel technology, applied in the field of cutting equipment for processing stainless steel products, can solve the problems of damage to stainless steel products, increase production costs, and the impossibility of flush processing of stainless steel products, etc., to avoid stamping and cutting, strong linkage, and low production costs and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

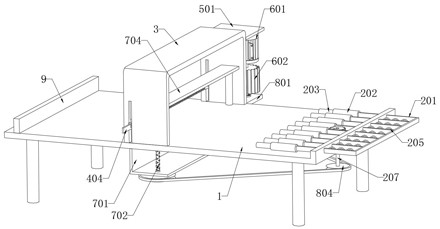

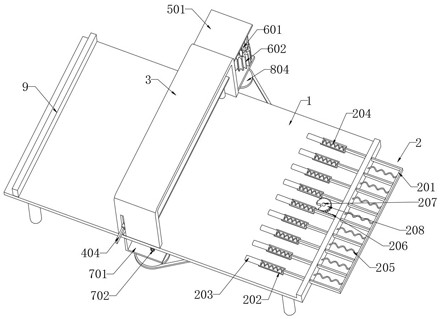

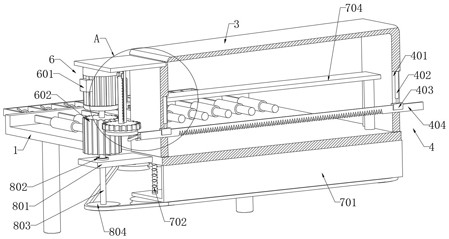

[0027] refer to Figure 1-7 , a cutting device for processing stainless steel products, including an L-shaped machine 1, an alignment plate 9 is detachably connected to the upper end of the machine 1, and it should be noted that the alignment plate 9 is detachably connected to the machine 1, which can be used for stainless steel The cutting size of the product is adjusted. The machine 1 is provided with an alignment mechanism 2 for aligning stainless steel products. The alignment mechanism 2 includes a sliding frame 201 slidably connected to the side wall of the machine 1. The sliding frame 201 is composed of a plurality of slide plates. The side wall is fixedly connected with a sleeve 202, the inner wall of the sleeve 202 is slidably connected with a push rod 203, one end of the push rod 203 is elastically connected with the inner wall of the sleeve 202 through a first spring 204, and the side wall of the machine 1 is connected with a plurality of second springs 205 The side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com