Short cold crucible for continuous melting and directional solidification flat blank

A technology of directional solidification and cold crucible, which is applied in the direction of crucible furnace, furnace cooling, furnace type, etc., can solve the problems of discontinuous melting of melt, low utilization rate of electric energy, poor melting of melt, etc., achieve good magnetic permeability and reduce energy Consumable, easy to observe and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

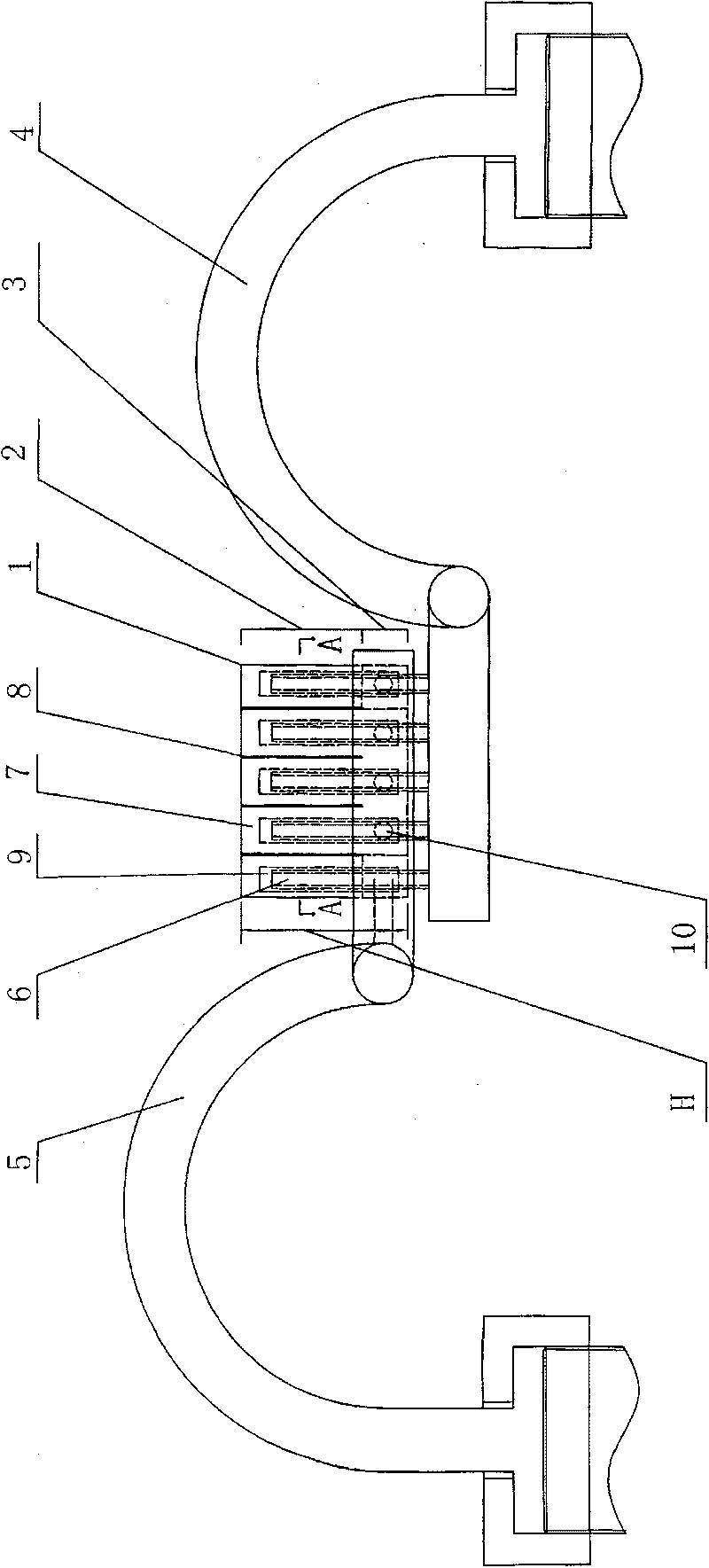

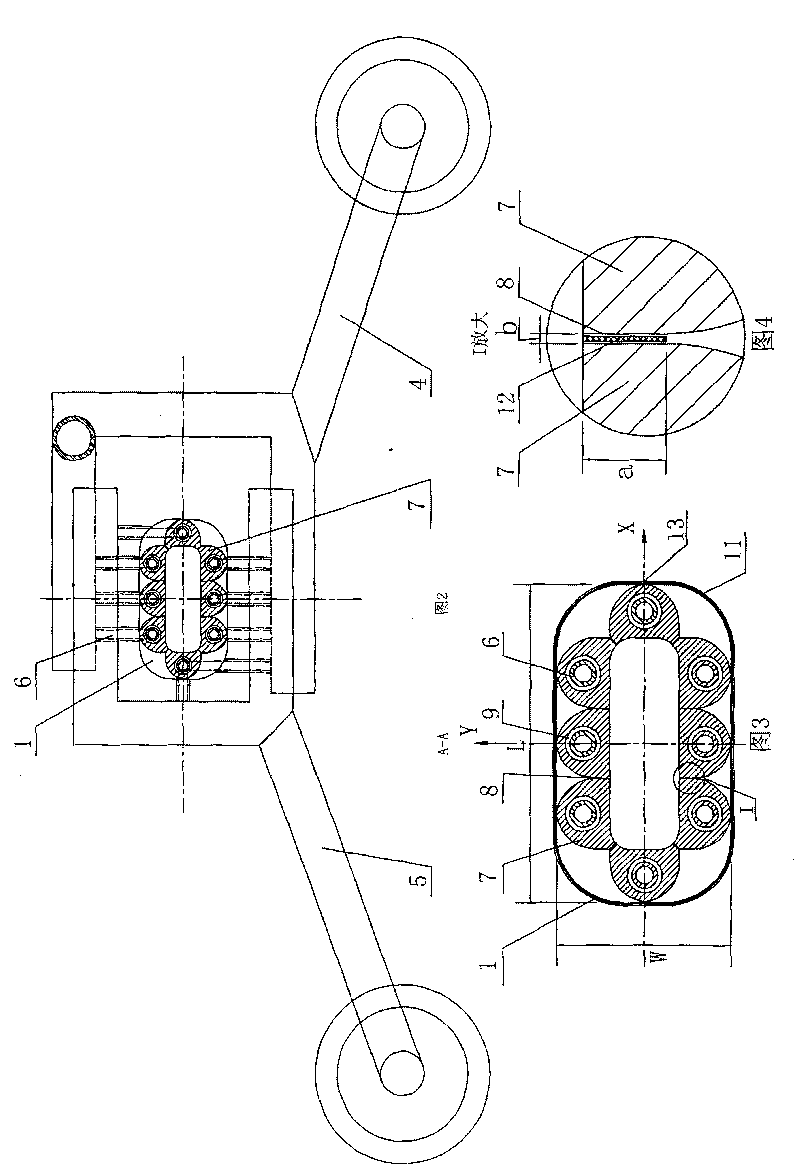

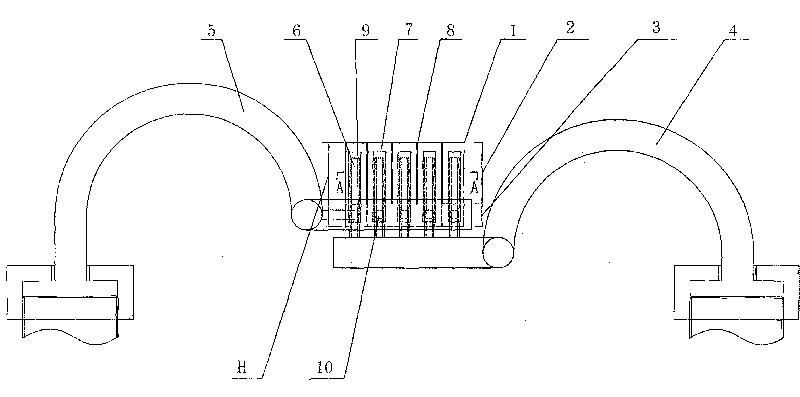

[0007] Specific implementation manner one: such as Figure 1 ~ Figure 3 As shown, the short cold crucible for continuous melting and directional solidification of slabs in this embodiment is composed of a water inlet pipe 4, a water outlet pipe 5, several thin water pipes 6, a copper crucible body 1, an induction coil 13, and a water inlet pipe 4 passing through Several thin water pipes 6 communicate with the copper crucible main body 1, and the water outlet pipe 5 communicates with the copper crucible main body 1 through several thin water pipes 6. The induction coil 13 is sleeved on the upper half 2 of the copper crucible main body 1; The horizontal cross-section of the copper crucible body 1 is a flat annular cavity. The copper crucible body 1 is composed of an upper body 2 and a lower body 3. The upper body 2 and the lower body 3 are integrated. The half body 2 is divided into eight petal-shaped cylinders 7 in horizontal cross-section, and eight petal-shaped cylinders 7 in ...

specific Embodiment approach 2

[0009] Embodiment 2: The insulating and sealing material layer 12 described in this embodiment is composed of natural mica flakes and epoxy resin. Choosing such a material has the best sealing and insulating effect. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation manner three: such as Figure 1 ~ Figure 3 As shown, the thin water pipe 6 described in this embodiment is welded to the water inlet pipe 4, the thin water pipe 6 and the water outlet pipe 5, and the thin water pipe 6 and the lower half 3 of the copper crucible body 1 are welded. With welding, it can withstand at least 10 atmospheric pressures. The other composition and connection relationship are the same as in the first embodiment.

[0011] Specific implementation manner 4: such as figure 1 with image 3 As shown, the length×width×height=L×W×H of the copper crucible body 1 according to this embodiment, wherein the length L is 70-80 mm, the width W is 40-50 mm, and the height H is 50-60 mm. The other composition and connection relationship are the same as in the first embodiment.

[0012] Specific implementation manner five: such as figure 1 with image 3 As shown, the length×width×height=L×W×H=72×44×55 mm of the red copper crucible body 1 describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com