Positioning device with positioning unit capable of linearity moving

A technology of positioning device and positioning unit, which is applied to electrical components, manufacturing tools, electrical components, etc., can solve the problems of affecting positioning accuracy and deterioration of vibration characteristics, and achieve the effects of saving space, reducing mass, and avoiding transitional oscillations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

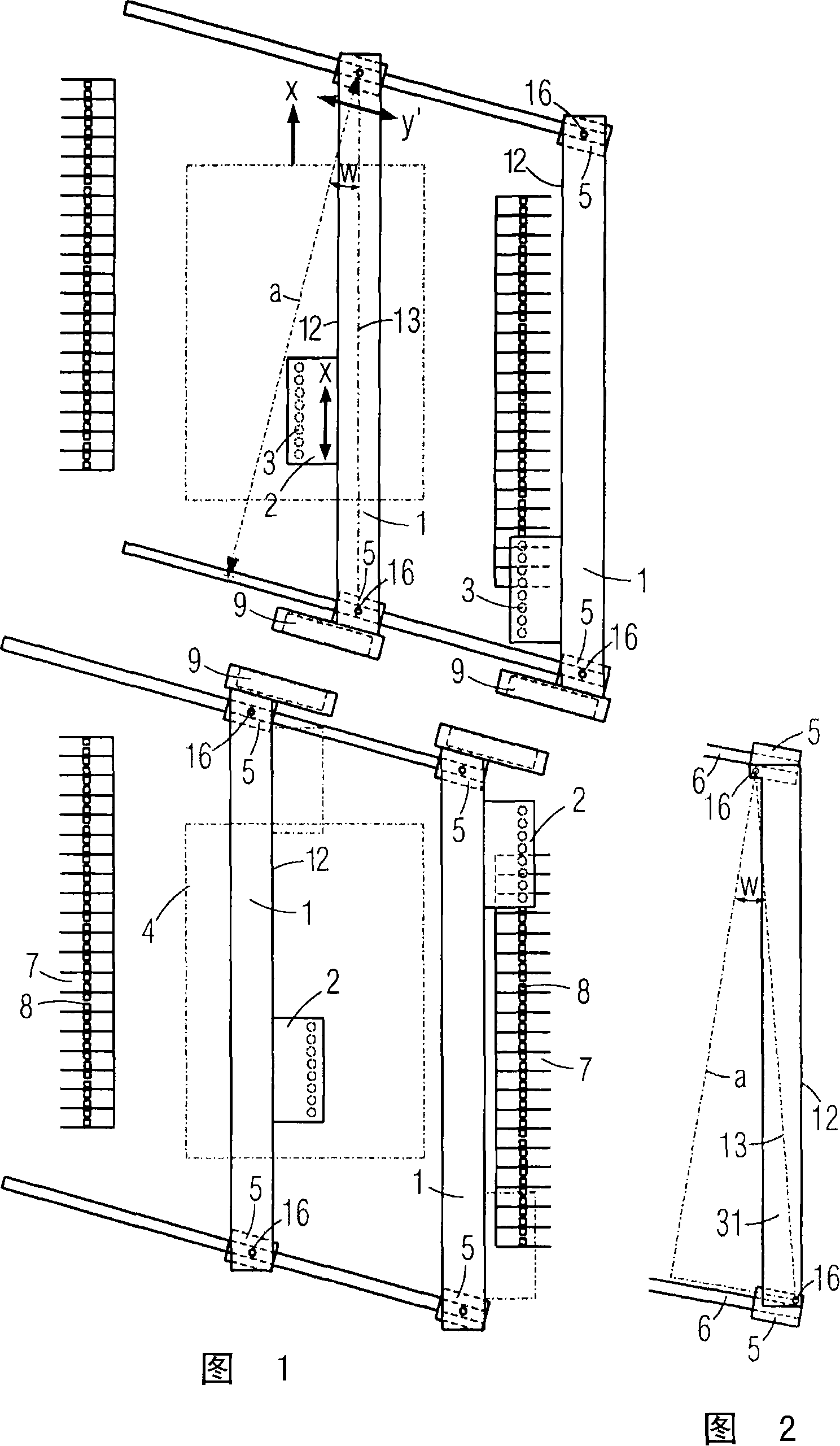

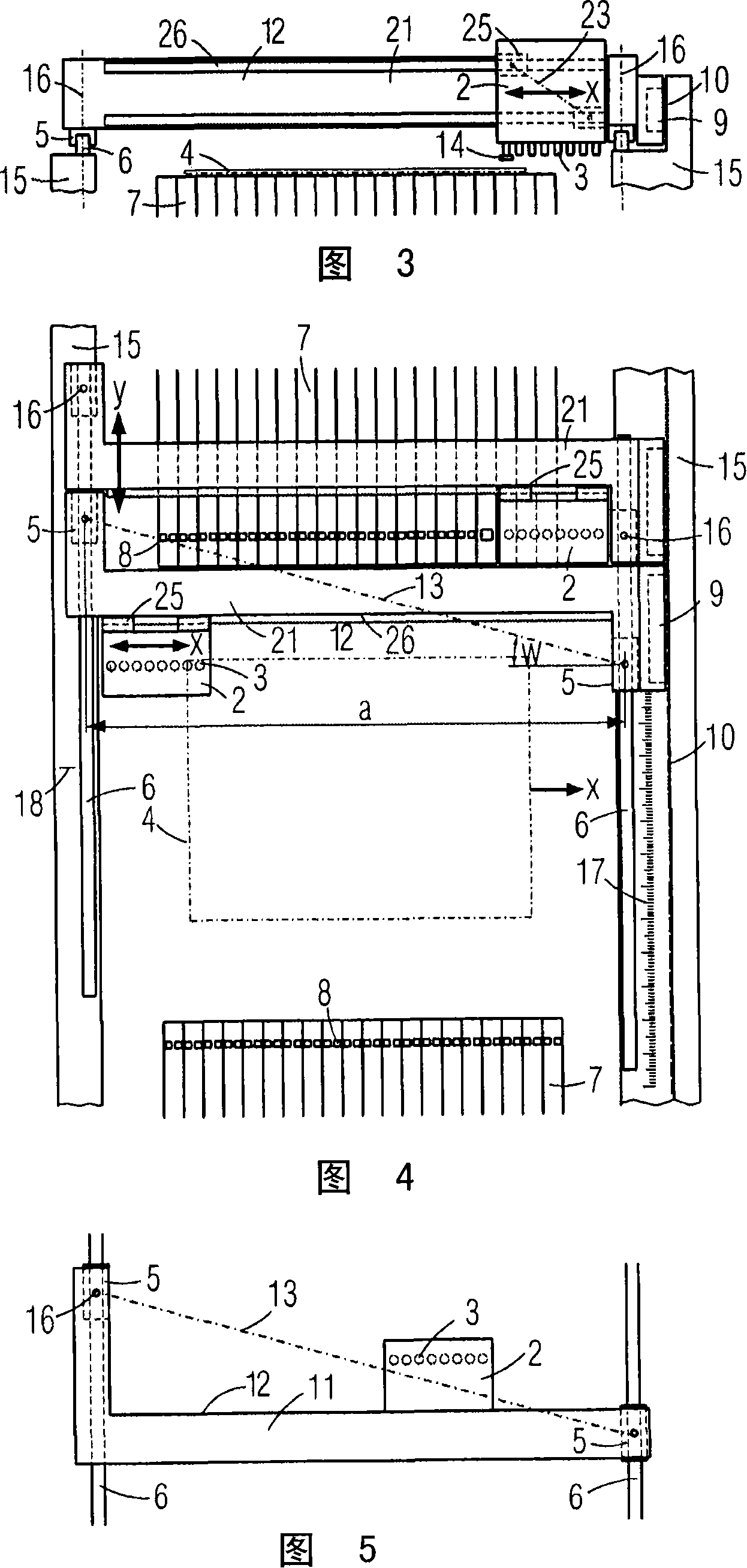

[0026] FIG. 1 shows the main functional unit of a equipping device with two equipping areas for substrates 4 arranged one behind the other in the transport direction x and with component transport mechanisms 7 arranged on their sides, which transport mechanisms have The components 14 aligned in the transport direction x are removed from the position 8 .

[0027] Above the two installation areas and the removal position 8, there are two slightly longer first positioning arms 1 oriented in the transport direction x, which can each be guided by a corresponding coil part 9 of a linear motor on mutually parallel stationary guide rails. 6 moves. The guide rail 6 in the form of a track extends obliquely with respect to the conveying direction in a first transverse direction y'. The first positioning arm 1 is guided at each end by means of a bearing 5 without play in one of the rail-shaped guide rails 6 .

[0028] The bearing 5, for example composed of a ball circulating element, ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com