Mechanism for coating adhesive used for medical instrument assembling

A technology of medical devices and adhesives, which is applied in the field of medical devices, can solve problems such as gluing of infusion filters, difficulty in controlling the amount of glue, and uneven application of glue, and achieve high stability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

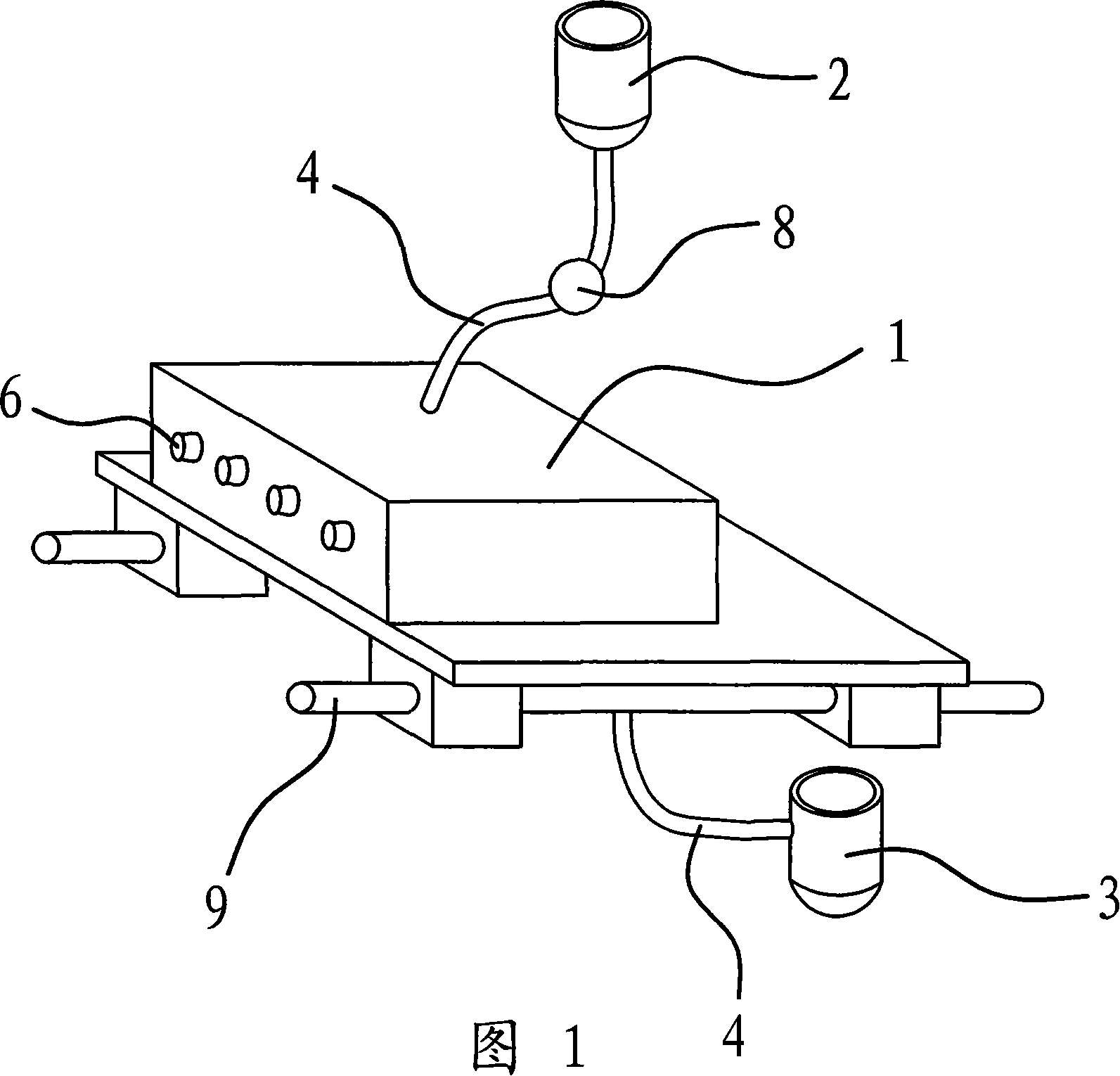

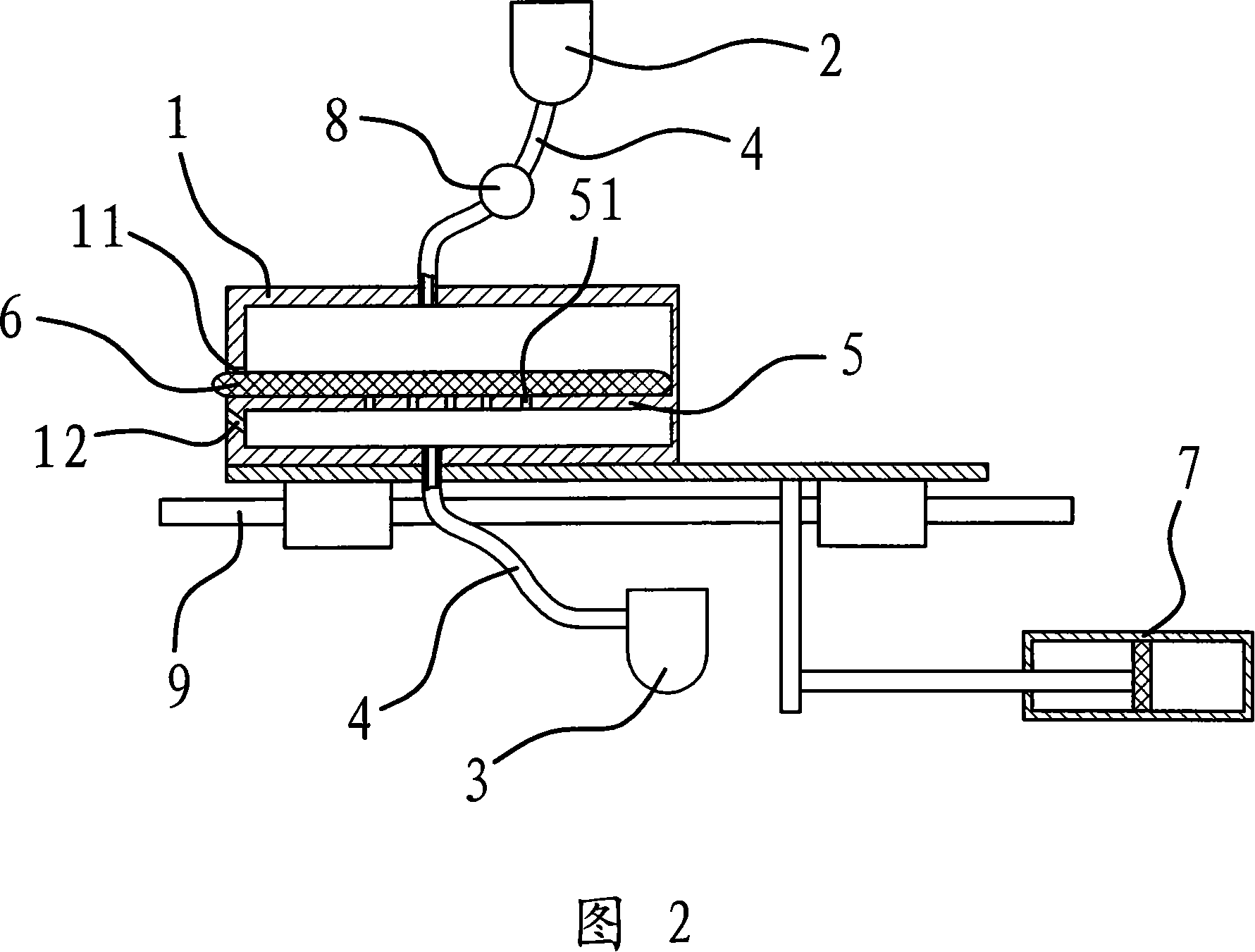

[0020] As shown in Figure 1 and Figure 2, the adhesive coating mechanism used for medical device assembly is arranged on the side of the station of the turntable of the infusion set dripping funnel assembly machine, which includes an adhesive box 1, an adhesive container 1 2. Adhesive container 2 3 and connecting pipe 4, etc.

[0021] The interior of the adhesive box 1 is a cavity, and a support plate 5 is provided in the adhesive box 1. The support plate 5 divides the adhesive box 1 into two cavities, the upper and lower cavities, and the support plate 5 has several through holes. 51. An opening 11 is provided on the side of the adhesive box 1 facing the working station, and a sponge body 6 is arranged inside the adhesive box 1, and the sponge body 6 slightly protrudes from the opening 11, and the shape of the opening 11 is circular.

[0022] The adhesive box 1 is located on the upper part of a base, and the adhesive box 1 is connected with the guide rail 9 of the base. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com