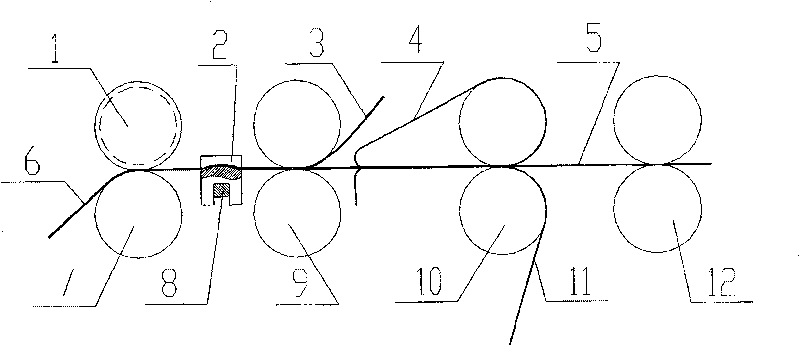

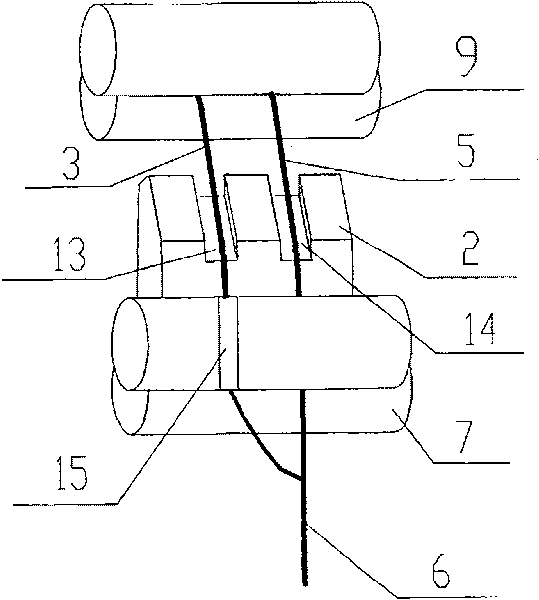

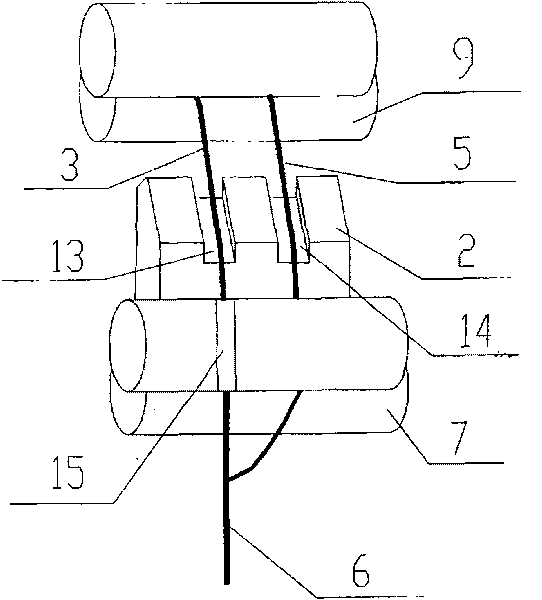

Device and method for spinning core-spun yarn

A core-spun yarn and equipment technology, applied in spinning machines, drafting equipment, continuous winding spinning machines, etc., can solve the problem of increasing the drafting burden of the drafting mechanism, unsuitability of the drafting mechanism, and affecting the quality of the sliver and other issues, to achieve the effect of easy promotion, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Use the equipment described in the present invention, and spin the core-spun yarn that 11.8tex polyester / cotton staple fiber covers cotton staple fiber according to the spinning short fiber / short fiber core-spun yarn method of the present invention. The process parameters are mainly as follows: the cotton fiber of the outer cladding layer has a long length, high count, and good maturity of combed cotton sliver, the main length of the fiber is 30mm; the polyester staple fiber of the core layer is selected as a cotton-type fiber with a length of 38mm, and the blending ratio is designed as Polyester / cotton = 49 / 51; the total draft ratio is designed to be 60 times; the tension draft from the front roller to the front roller is selected to be 1.3 times; the spinning twist coefficient is designed to be 300.

[0035] The polyester / cotton staple core-spun yarn spun in this example has a coverage rate of 96% and has good peeling resistance.

Embodiment 2

[0037] Use equipment described in the present invention, spin the core-spun yarn that 23.62tex cotton staple fiber is coated with polyester filament according to the spinning filament / short fiber core-spun yarn method of the present invention. The process parameters are mainly as follows: carded sliver with a main body length of 29mm is used for the outsourcing cotton fiber, and 75 denier polyester is selected as the core chemical fiber filament; The draft ratio E between is based on E=πD 1 / D 2 (=0.0987π / 0.0156) calculated by the formula is 1.987. The spinning twist coefficient is designed to be 320.

[0038] The polyester filament core-spun yarn covered with cotton staple fibers spun in this embodiment has a covering rate of 95% and has good peeling resistance.

Embodiment 3

[0040] Use equipment described in the present invention, in conjunction with short fiber / short fiber core-spun yarn method and filament / short fiber core-spun yarn method of the present invention, spinning polyester filament / viscose staple fiber / cotton fiber three-layer bag core yarn.

[0041] In this embodiment, the core yarn filament is selected from 50-denier polyester, the viscose is selected from 38mm cotton-type fiber carded slivers, the cotton fiber is the same as in Example 2, and other relevant process parameters are the same as in Example 2. The process is to implement the two staple fiber strips of viscose staple fiber / cotton fiber according to the method described in Example 1, and implement the polyester filament according to the method described in Example 2, and make the polyester filament be output together with it. The middle positions of the two staple fiber strands are twisted together outside the leading jaws to obtain a three-layer core-spun yarn of core ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com