Combined cooling structure for turbine blade middle-part porous impact aerating film

A technology of turbine blades and cooling structure, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problem of insufficient cooling of blades, and achieve the effect of improving heat exchange, reducing flow resistance and improving cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

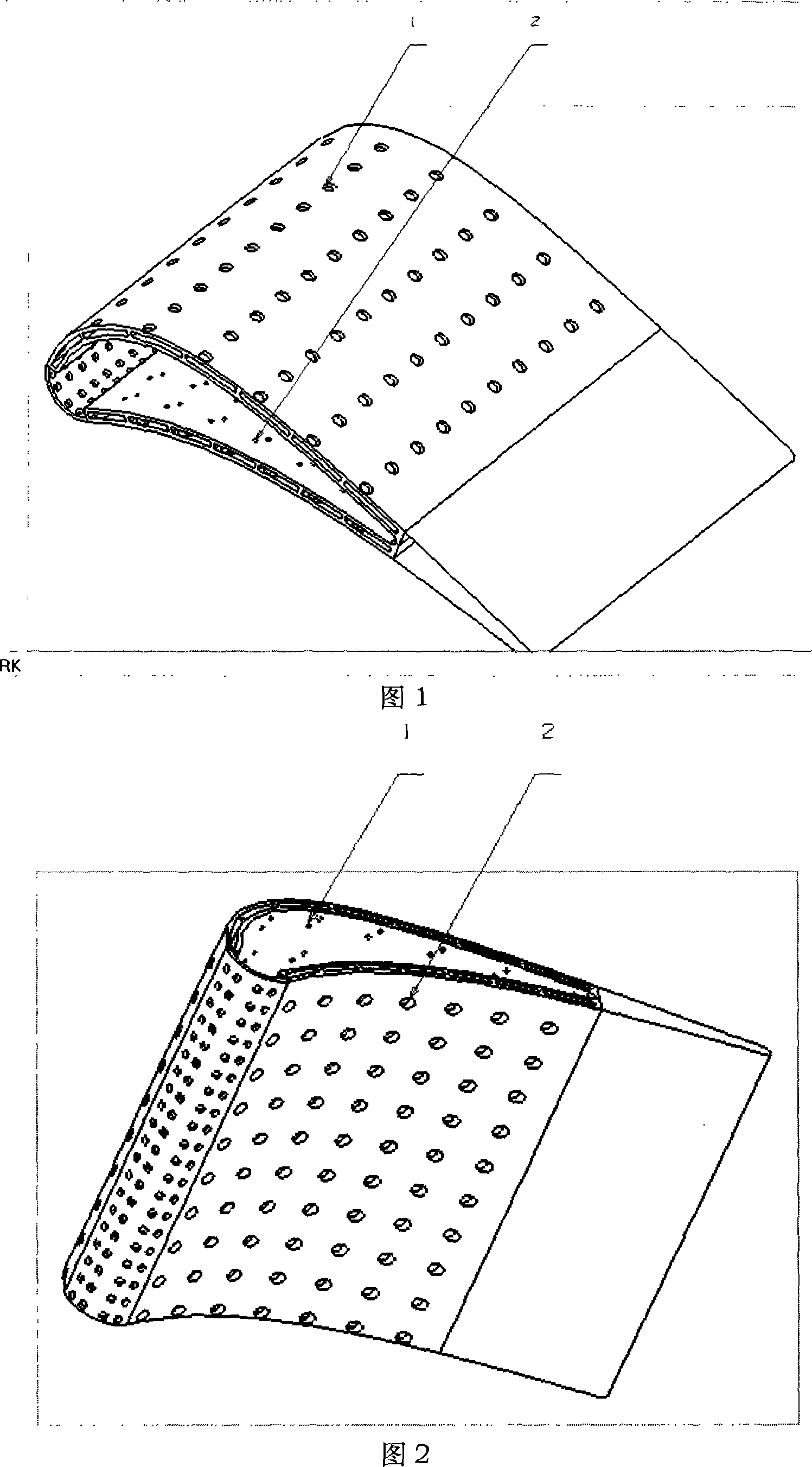

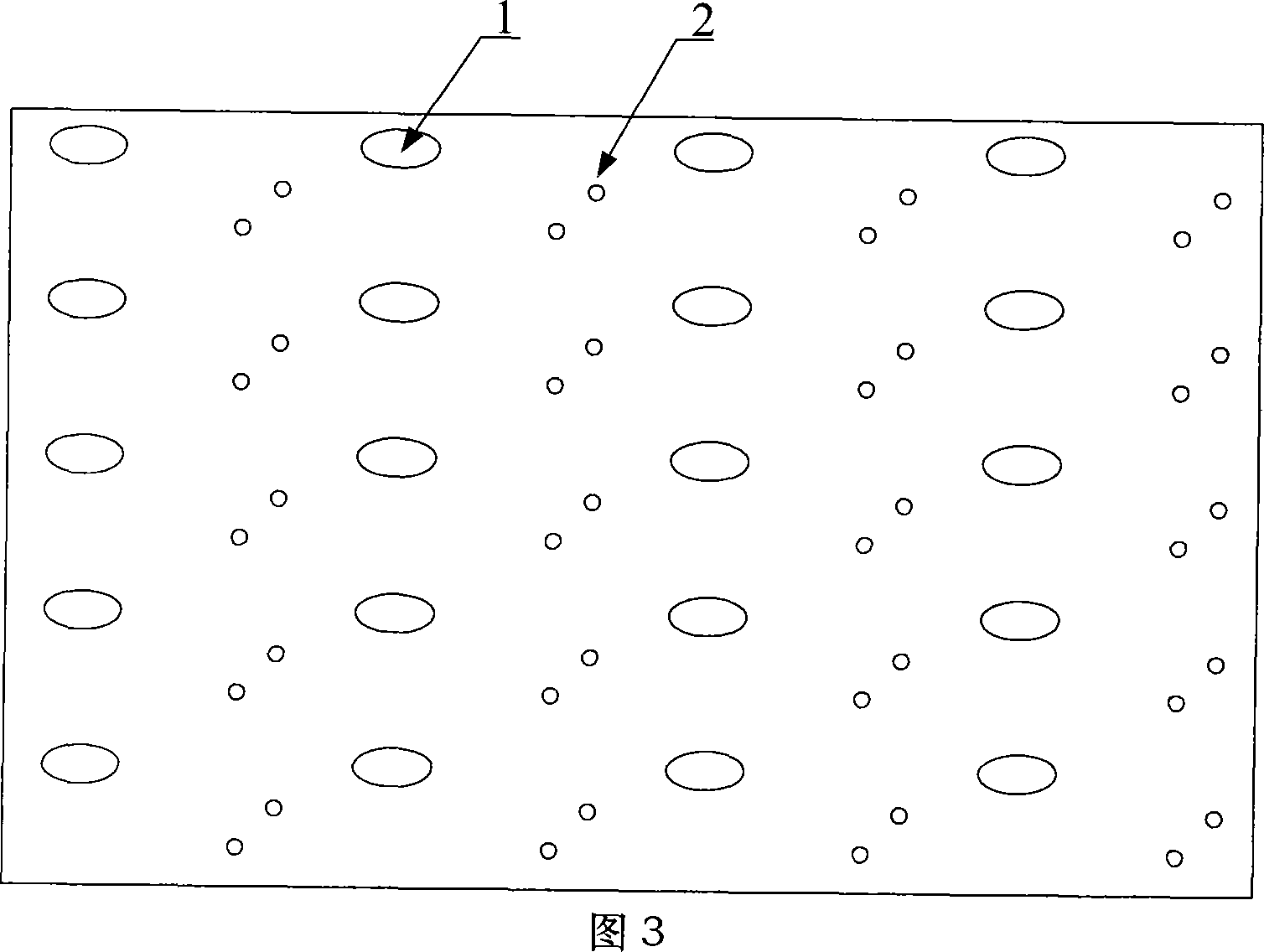

[0014] As shown in Fig. 1, the present invention is a combined cooling structure of a porous impingement air-entraining film applied to the middle part of an aeroengine turbine blade, which includes: air film holes and impact holes, characterized in that: arranged on the outer surface of the blade Air film holes with a diameter of 1.0mm to 1.5mm, the number of each exhaust film hole in the span direction is 10 to 15, and the impact holes equivalent to twice the number of air film holes are arranged in the downstream area of the air film holes inside the blade , the diameter of the impact hole is 0.6mm~08mm, the impact hole is arranged in the range of 7~10 times the diameter of the impact hole downstream of the corresponding air film hole, and is located between the two air film holes, the impact holes are arranged in a staggered manner, and the adjacent The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com