Photosensitive resin composition for forming light shielding layer, light shielding layer and color filter

A technology of photosensitive resin and light-shielding layer, which can be used in optical filters, photosensitive materials for optical mechanical equipment, optics, etc., and can solve problems such as poor curing, low sensitivity, and insufficient exposure light transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0126] According to JP-A-2001-354735, add 235g of bisphenol olefin type epoxy resin (235 epoxy equivalent) and 110mg of tetramethylammonium chloride, 2,6-di-tert-butyl-4-methyl 100 mg of base phenol and 72.0 g of acrylic acid were blown into them with air at a rate of 25 mL / min, while heating at 90 to 100° C. to dissolve.

[0127] Next, while the solution was in a cloudy state, the temperature was slowly raised, and it was heated to 120° C. to completely dissolve it. The solution gradually became transparent and viscous, but continued to stir.

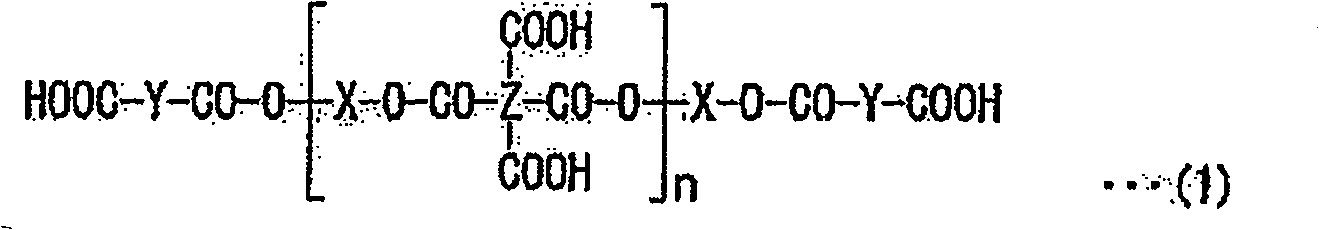

[0128] During this time, the acid value was measured, and stirring was continued until it became less than 1.0 mgKOH / g. It takes 12 hours for the acid value to reach the target. Then, it cooled to room temperature, and the bisphenol olefin type epoxy acrylate represented by the following chemical formula (3) of a colorless transparent solid state was obtained.

[0129] [chemical 13]

[0130]

[0131] Next, 600 g of propylene gly...

Embodiment 1

[0134] Each component was mixed in the following formulation, and the photosensitive resin composition for light-shielding layer formation was prepared.

[0135] As the (B) alkali-soluble resin, 100 parts by mass of Compound 1 obtained in Synthesis Example 1 above was used.

[0136] As (C)component, 50 mass parts of dipentaerythritol tetraacrylates were used.

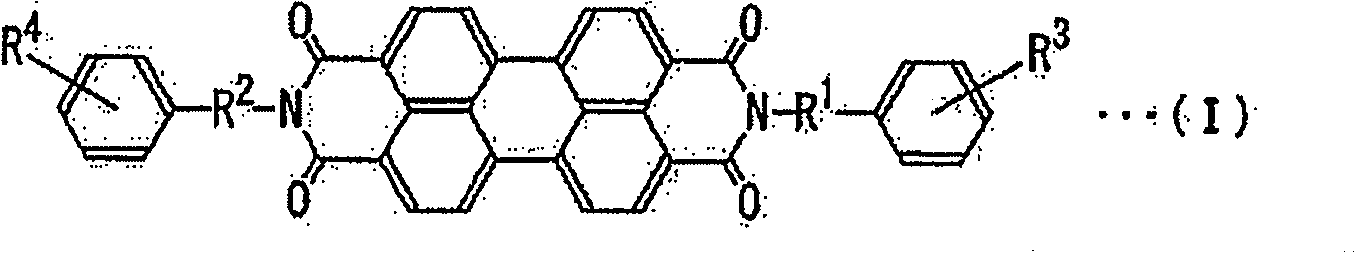

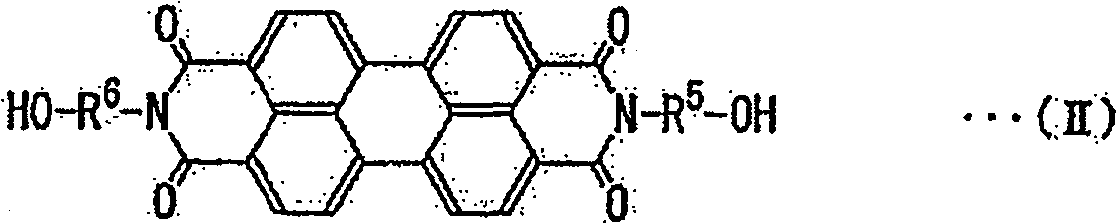

[0137] As (A) a light-shielding dye, 30 parts by mass of a perylene-based black pigment dispersion (C.I. Pigment Black 31: 15%, dispersant 10%, solvent: PGMEA) was used.

[0138] As (D) photopolymerization initiator, 30 parts by mass of CIBASPECIALTY CHEMICALS product name: Irgacure 369, compound name: 2-benzyl-2-dimethylamino-1-(4- Morpholinophenyl)-butane-1-one.

[0139] As (E) organic solvent, the mixed solvent whose mass ratio PGMEA:3-methoxybutyl acetate is 1:3 was used. The usage-amount of the organic solvent was adjusted so that the solid content concentration might become 30 mass %.

[0140] The photosensiti...

Embodiment 2

[0147] In the compounding of Example 1, instead of 30 parts by mass of the perylene-based pigment dispersion, 40 parts by mass were used to mix the perylene pigment dispersion and the carbon black dispersion "CF" at a ratio of 90:10. The pigment mixture obtained from Black EX-1455" was used to prepare a photosensitive resin composition for forming a light-shielding layer.

[0148] Using the photosensitive resin composition for forming a light-shielding layer obtained, it was carried out in the same manner as in Example 1 to form a coating film at 30 mJ / cm 2 exposure. After the exposure, it was developed by spraying for 60 seconds with a potassium hydroxide 0.04% developing solution. Furthermore, post-baking was performed at 200 degreeC for 30 minutes, and the black matrix of the matrix pattern of 20 micrometers with a film thickness of 3 micrometers, a dot pattern, and an isolated pattern was formed. The OD value of the formed black matrix was 4.5.

[0149] The shape of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com