Coating device

A technology of coating device and driving device, which is applied to devices for coating liquid on the surface, coatings, photo-engraving process coating equipment, etc. problem, to achieve stable coating and suppress undulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

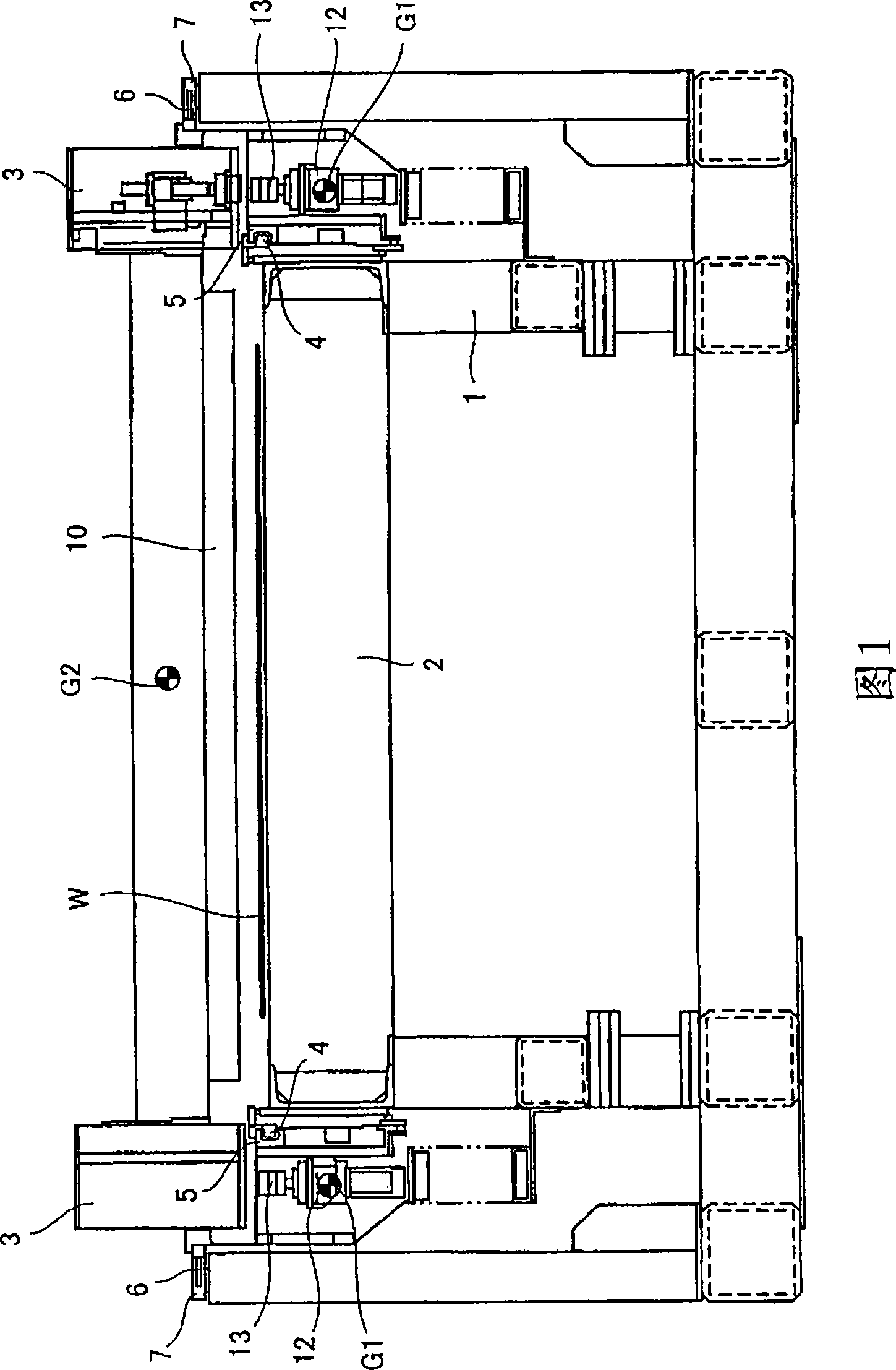

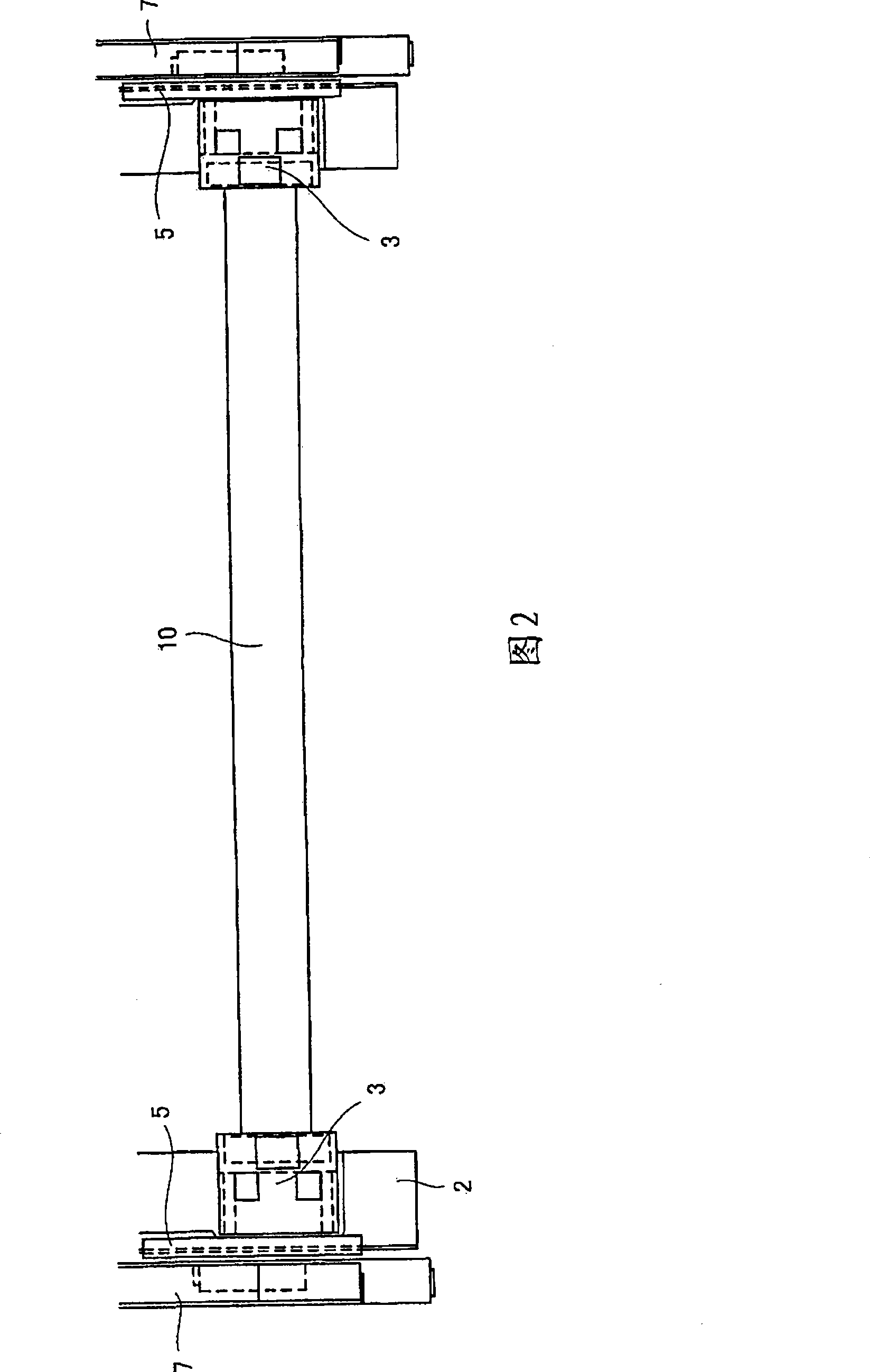

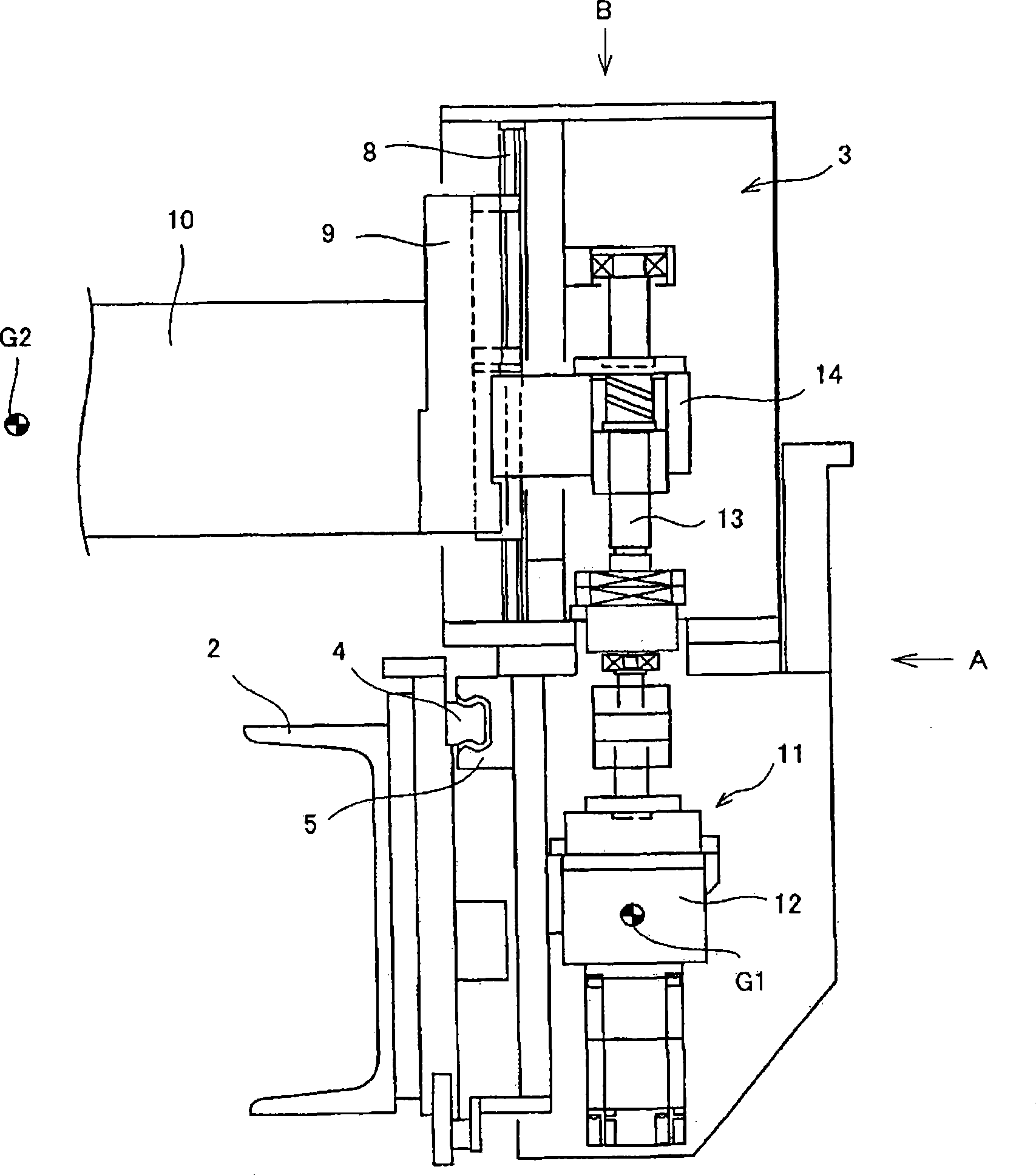

[0025] Embodiments of the present invention will be described below with reference to the drawings. figure 1 is a side view of the coating device of the present invention, figure 2 yes figure 1 The top view of the main part of the image 3 is an enlarged view of the drive unit, Figure 4 yes image 3 A direction to the view, Figure 5 yes image 3 View from direction B.

[0026] As for the coating device, a stage 2 on which a substrate W is placed is fixed on a base 1, and moving bodies 3, 3 are arranged along both sides of the stage 2, and the moving body 3 moves in the horizontal direction (with figure 1 The vertical direction of the paper surface) is removable.

[0027] In this embodiment, the mobile body 3 is moved by a linear motor. That is, rails 4 , 4 are provided on the side frames of the stage 2 , and the rails 4 engage with the guide grooves 5 of the moving body 3 . Then, the stator 6 of the linear motor is arranged parallel to the above-mentioned rail 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com