Control device for reverse gear self-locking

A control device and reverse gear technology, applied in the direction of transmission control, toothed components, belts/chains/gears, etc., can solve the problems of complex structure, engine damage, high cost, etc., and achieve simple and compact structure and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

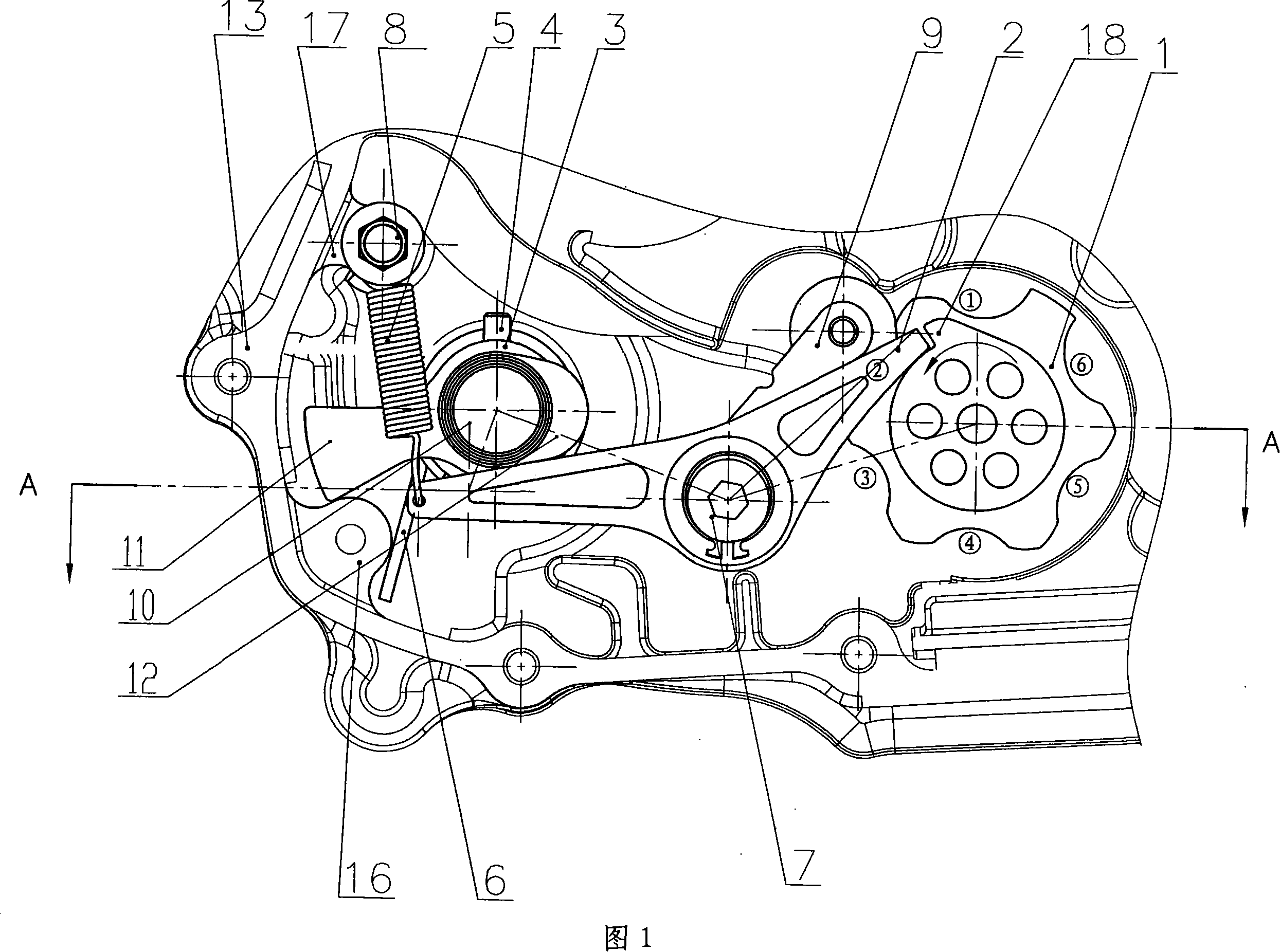

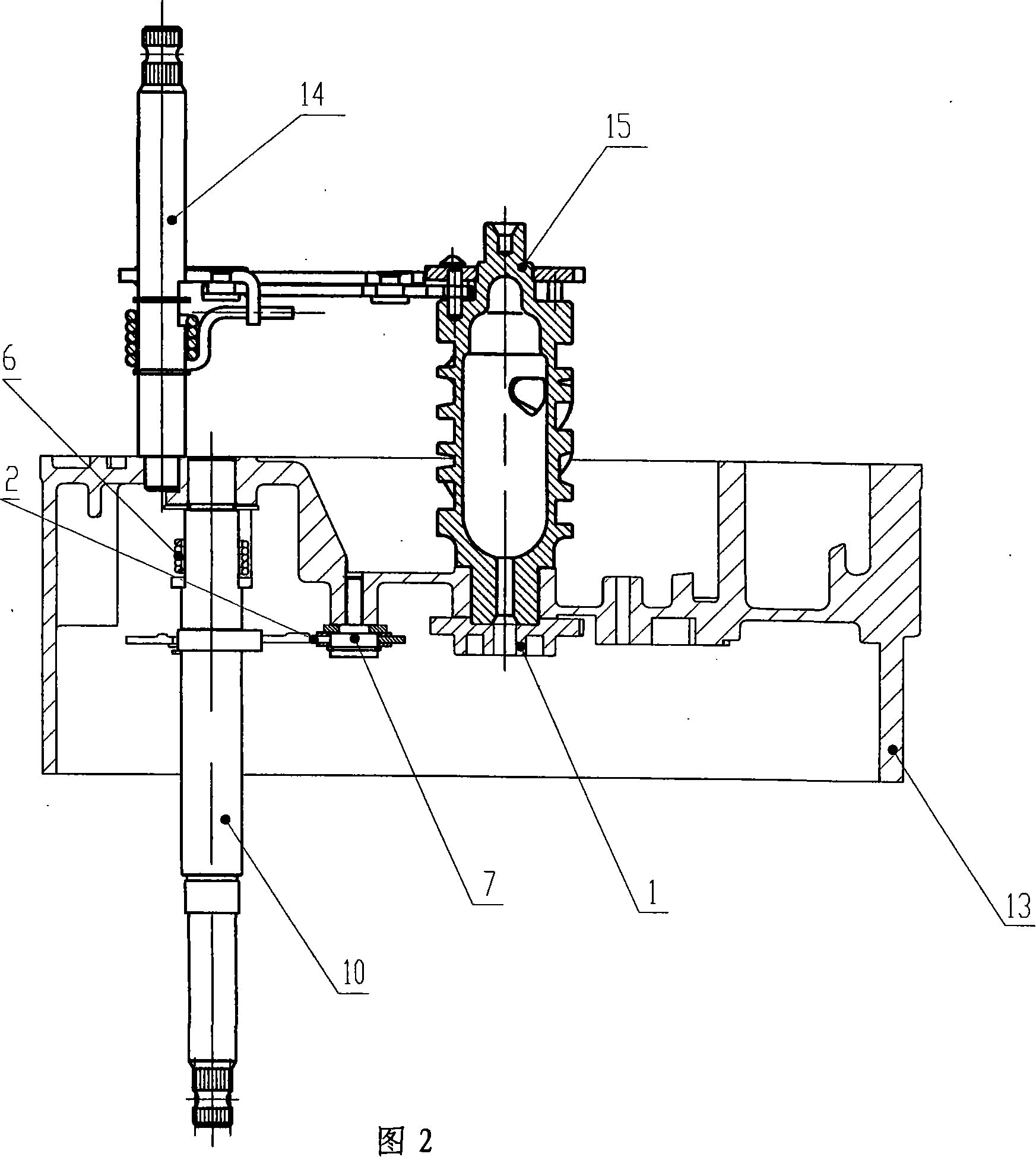

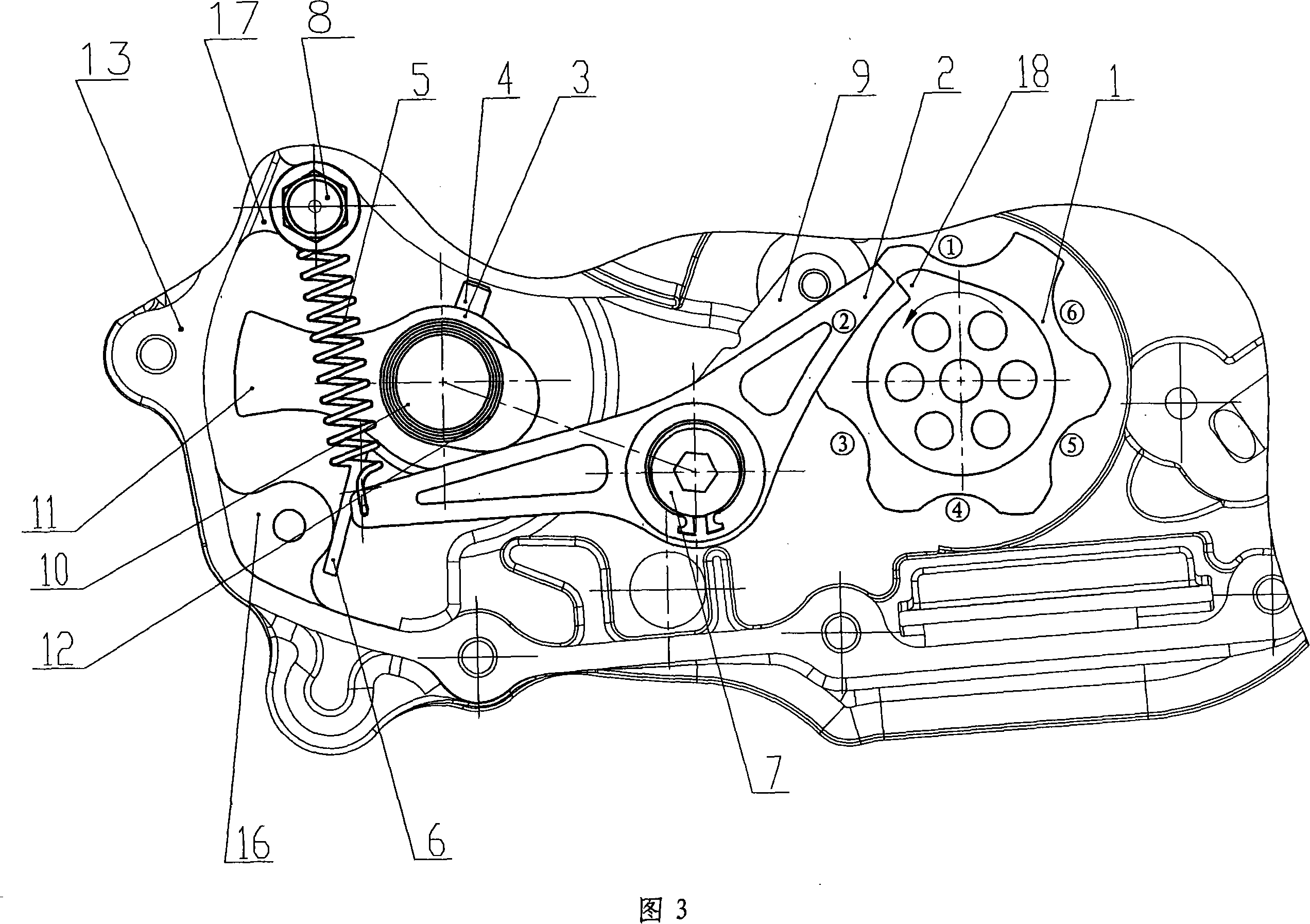

[0013] Fig. 1 to Fig. 4 ask, for the present invention creates a kind of specific embodiment of reverse gear self-locking control device, and it comprises right casing 13, shift drum 15, shift positioning plate 1, shift shaft assembly 14, stop The actuator assembly 9, the shift drum 15 is arranged on the right box body 13, the shift positioning plate 1 is fixed on the shift drum 15, and the gear position is set on the shift positioning plate 1, as shown in Figure 1, ① is Reverse gear, ② is neutral gear, ③ is first gear, ④ is second gear, ⑤ is third gear, ⑥ is fourth gear, and stopper assembly 9 controls the gear position of shift positioning plate 1, and the shift positioning plate 1 is provided with a limit stop convex point 18 or a groove, and the reverse gear rocker arm 2 is hinged on the right box 13 through a bolt 7, and one end of the reverse gear rocker arm 2 is connected to the limit stop bump 18 or groove Matching, between the other end of the reverse gear rocker arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com