Suspension filling clarifier tank

A technology of suspended filler and clarifier, applied in sustainable biological treatment, flocculation/sedimentation water/sewage treatment, aerobic process treatment, etc., can solve the problem of sludge loss in secondary settling tanks, limit the treatment capacity of sewage treatment plants, and occupy an area Large area and other problems, to achieve the effect of increasing sinking speed, good operating efficiency and improving clarification ability

Inactive Publication Date: 2010-08-25

TONGJI UNIV +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are many problems in the actual project operation of the secondary sedimentation tank: ①The area is huge: the surface load of the secondary sedimentation tank is generally controlled at 0.6-0.8m 3 /m 2 .h, the area occupied by the entire secondary settling tank area is even close to that of the biological reaction tank, which limits the potential of the sewage treatment plant to increase the treatment capacity; There is floating mud problem. In some local sewage plants, even during heavy rainfall in the rainy season, sludge loss often o

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0013] Detailed ways

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

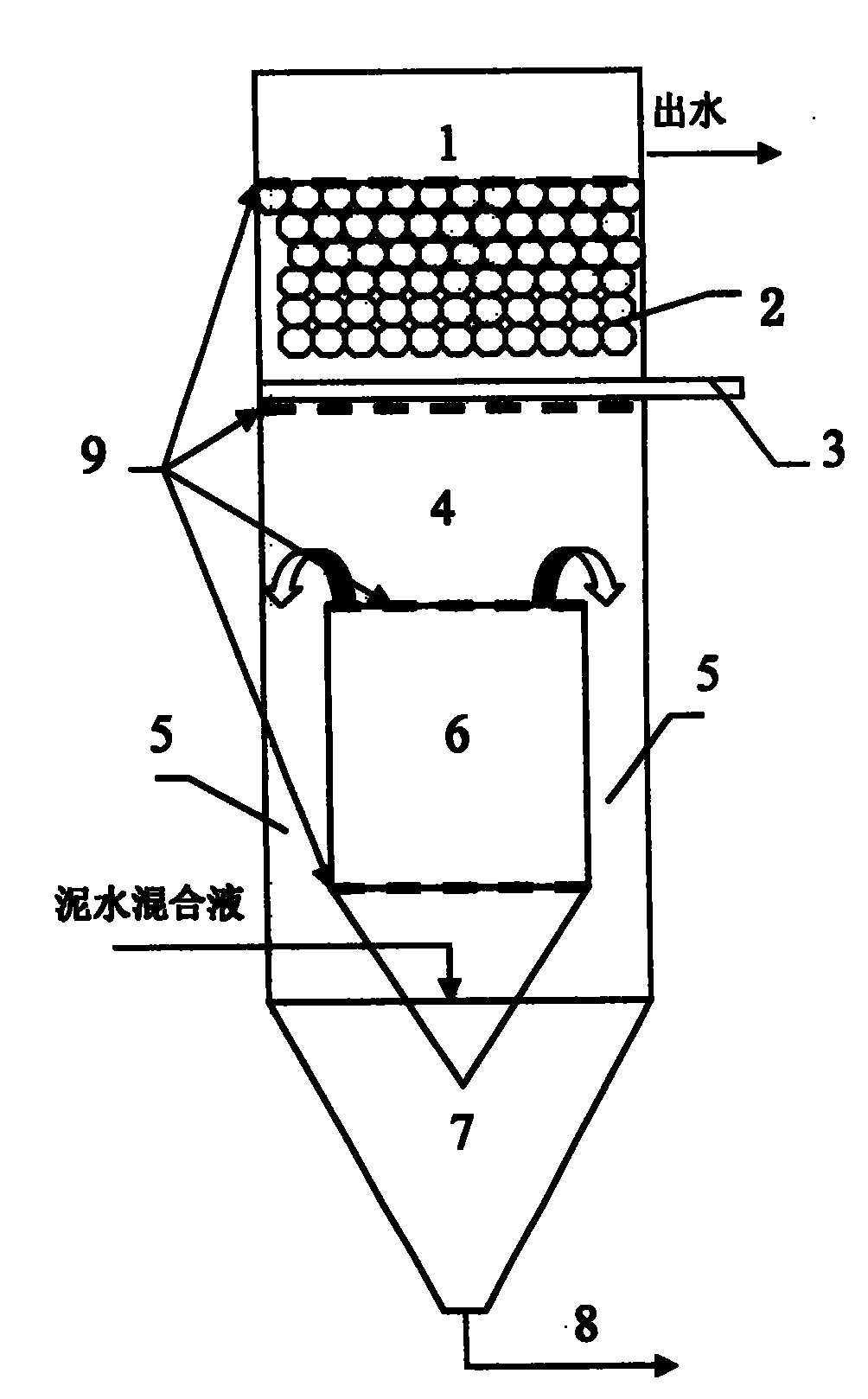

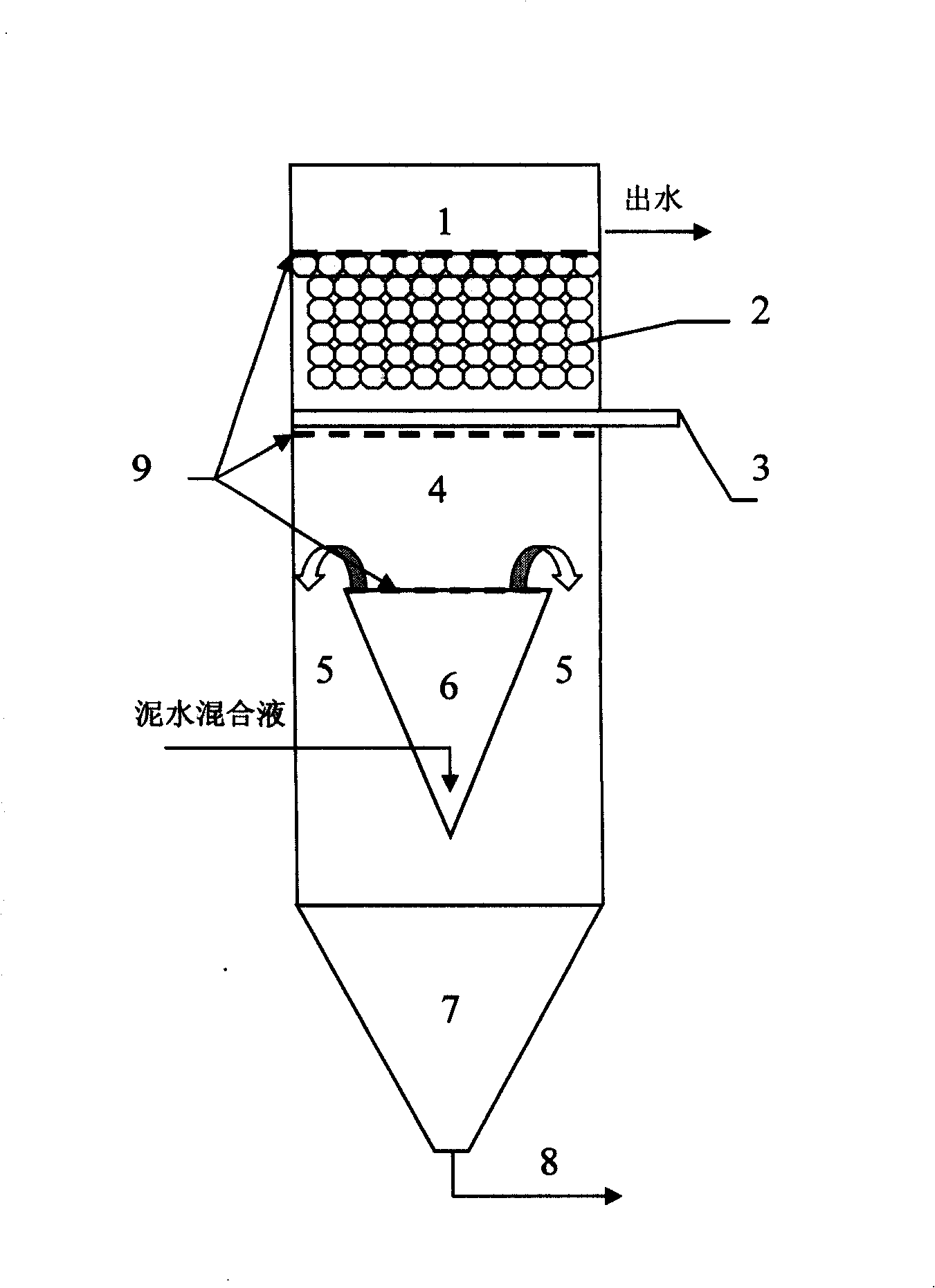

The present invention relates to sewage biotreating technology, and is especially one suspended stuffing clarifier for solid-liquid separation of fluent from bioreaction tank to treat sewage biologically in an active sludge process or biomembrane process. The suspended stuffing clarifier consists of one clear water area, one stuffing trapping area, one aerating pipe, one sludge flocculating area,one sludge overflowing area, one fairing area, one sludge concentrating area, one draining pipe and one grating. The suspended stuffing clarifier may be set alone or through combination with bioreaction tank. It has high solid-liquid separation effect, low cost and other advantages.

Description

technical field [0001] The suspended filler clarifier relates to the biological treatment sewage technology, and is applied to the activated sludge method or the biological membrane method sewage biological treatment process to separate the mixed liquid flowing out of the biological reaction tank from solid and liquid. Background technique [0002] The activated sludge or biofilm sewage treatment process system generally consists of a biological reaction tank and a secondary sedimentation tank (referred to as secondary sedimentation tank), of which the secondary sedimentation tank undertakes two functions of effluent clarification and sludge concentration. However, there are many problems in the actual project operation of the secondary sedimentation tank: ①The area is huge: the surface load of the secondary sedimentation tank is generally controlled at 0.6-0.8m 3 / m 2 .h, the area of the entire secondary sedimentation tank area is even close to the biological reaction ta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/02C02F1/52

CPCY02W10/10

Inventor 董滨周增炎高廷耀傅钢

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com