Rotating shaft fixed structure

A technology with a fixed structure and a rotating shaft, applied in the direction of the structure of the telephone, can solve problems such as affecting the appearance of the mobile phone, and achieve the effect of preventing the surface from shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

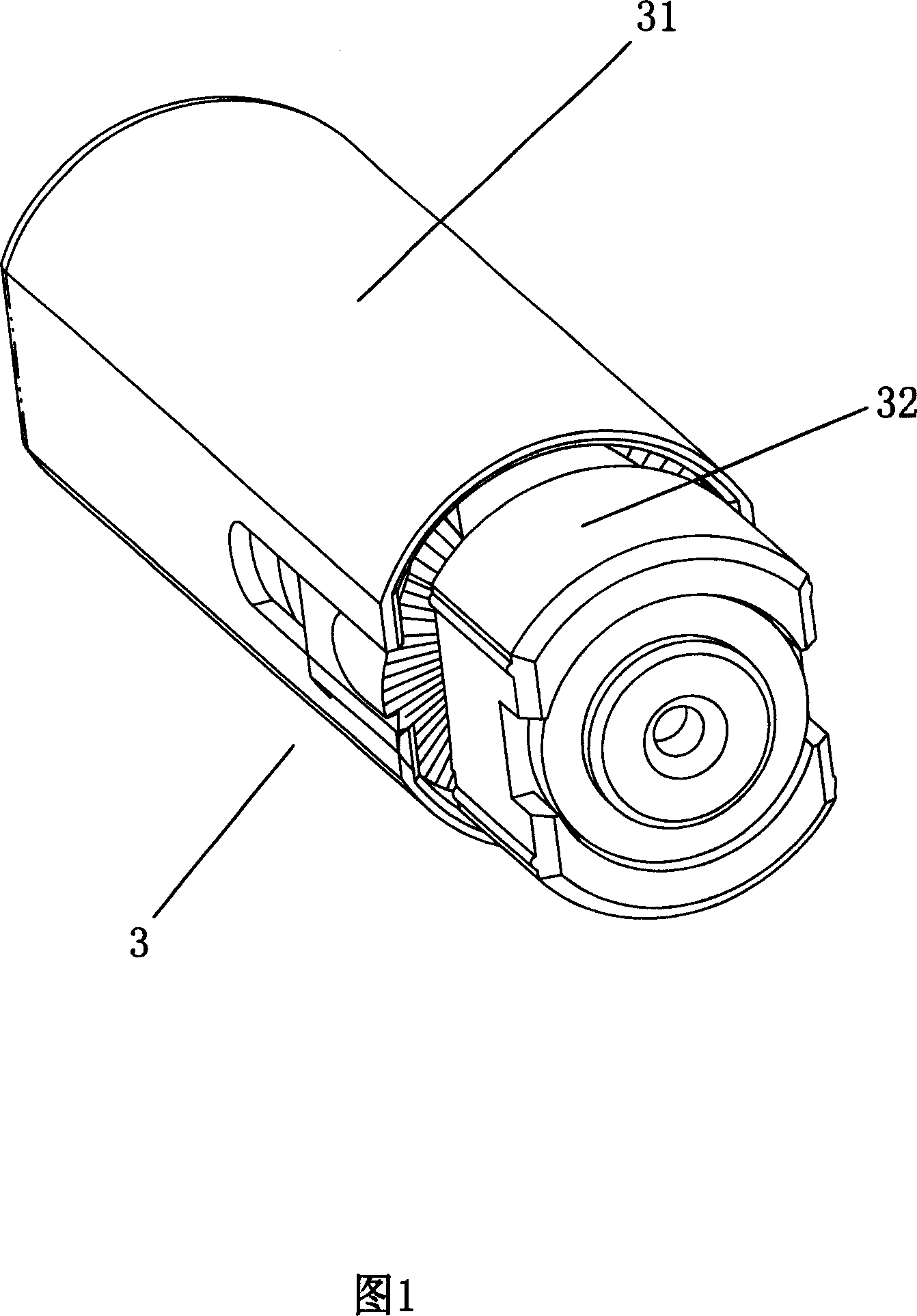

[0021] Please refer to FIG. 1 to FIG. 10 , the rotating shaft fixing structure of the present invention includes a main casing 1 , a flip casing 2 and a rotating shaft 3 , and the flip casing 2 is rotatably mounted on the main casing 1 through the rotating shaft 3 .

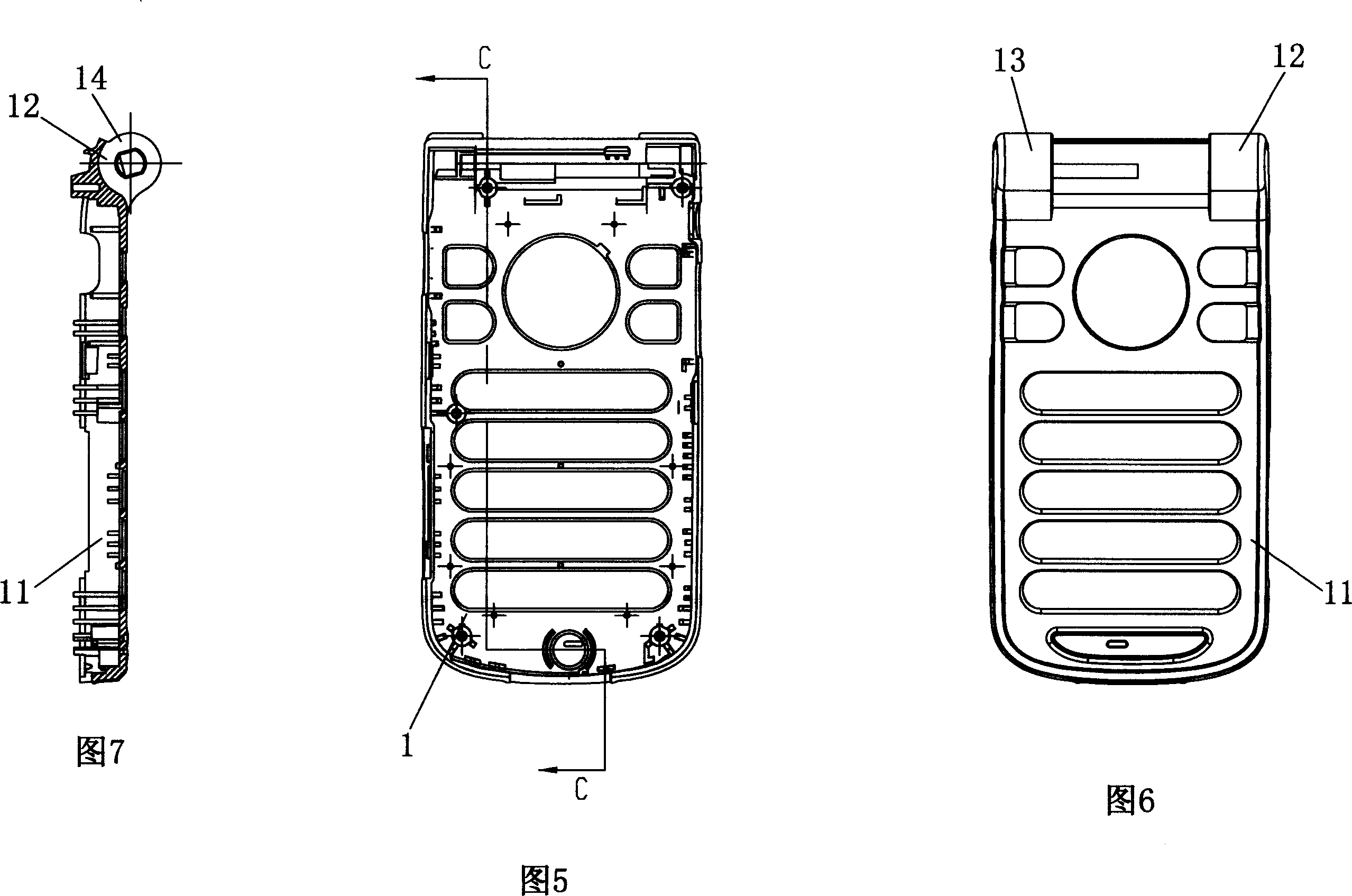

[0022] The main housing 1 includes a main housing body 11 and first and second mounts 12, 13 protruding from the surface of the body 11. In the axial direction of the rotating shaft 3, the first and second mounts 12, 13 arranged at intervals, the surface of the first mount 12 facing the second mount 13 is recessed with a first rotating shaft hole 14, the second mount 13 faces the first mount 12 The first rotating shaft hole 15 is recessed on the surface, and the first rotating shaft hole 14 and the first rotating shaft hole 15 are coaxial with the rotating shaft 3 .

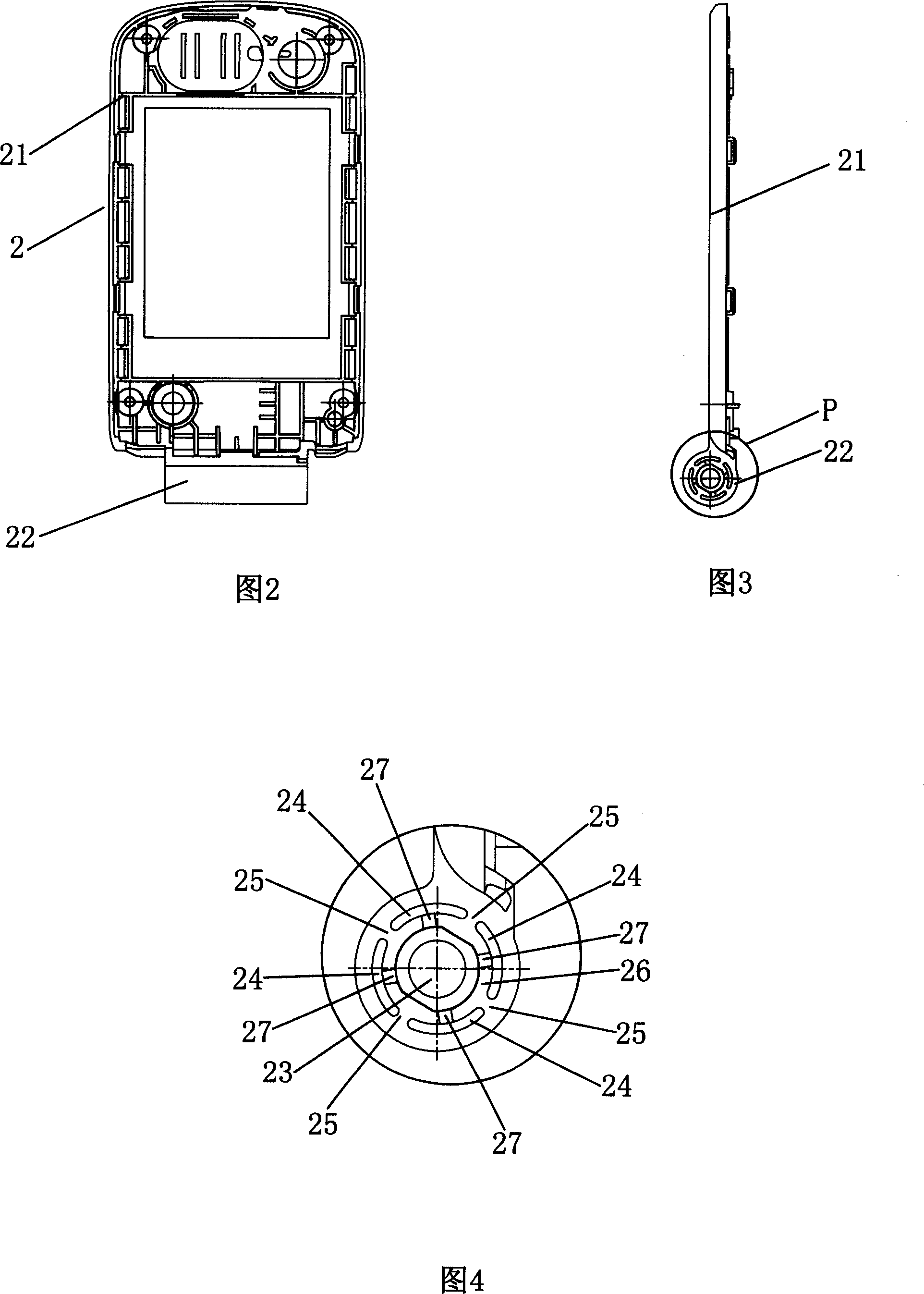

[0023] The flip case 2 is made of PC plastic, which includes a flip case body 21 and a mating seat 22 protruding from one side of the body 21. 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com