Extinction film or diaphragm and preparation method for same

A film and film technology, applied in the field of matte film or film and its preparation, can solve the problems of increased gloss, insufficient matting performance of products, difficult processing, etc., achieves excellent heat resistance of texture, wide industrial application prospects, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

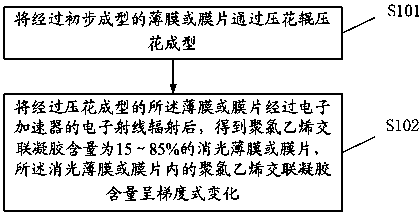

Method used

Image

Examples

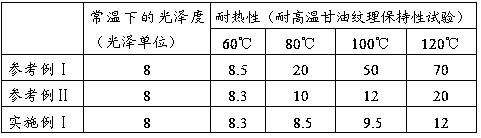

Embodiment 1

[0126] 100 parts of polyvinyl chloride resin with a polymerization degree of 500~2800, 0.1 part of sensitizer trimethylolpropane trimethacrylate, 1 part of plasticizer di-n-butyl phthalate, 0.1 part of stabilizer stearin Calcium acid is used as a raw material, and a film or diaphragm is obtained through a calendering process. The film or film is embossed by an embossing roller to obtain a film or film with a glossiness of 2 and a low-gloss matte surface. Then pass the film or film on the low-gloss matte surface through an electron accelerator with a radiation voltage of 20KV, and use an electron ray radiation with a radiation dose of 10KGy to obtain a matte film or film with a polyvinyl chloride cross-linked gel content of 15%. piece.

Embodiment 2

[0128] 100 parts of polyvinyl chloride resin with a polymerization degree of 500~2800, 5 parts of sensitizer trimethylolpropane triacrylate, 20 parts of plasticizer dioctyl phthalate, 3 parts of stabilizer barium stearate As a raw material, a film or diaphragm is obtained through a calendering forming process. The film or film is embossed by an embossing roller to obtain a film or film with a glossiness of 5 and a low-gloss matte surface. Then pass the film or film on the low-gloss matte surface through an electron accelerator with a radiation voltage of 80KV, and use an electron ray radiation with a radiation dose of 50KGy to obtain a matte film or film with a polyvinyl chloride cross-linked gel content of 35%. piece.

Embodiment 3

[0130] 100 parts of polyvinyl chloride resin with a polymerization degree of 500~2800, 8 parts of sensitizer diethylene glycol diacrylate, 80 parts of plasticizer diisooctyl isophthalate, 5 parts of stabilizer stearic acid Zinc is used as a raw material, and a thin film or diaphragm is obtained through a calendering forming process. The film or film is embossed by an embossing roller to obtain a film or film with a glossiness of 6 and a low-gloss matte surface. Then pass the film or film on the low-gloss matte surface through an electron accelerator with a radiation voltage of 150KV, and use an electron ray radiation with a radiation dose of 80KGy to obtain a matte film or film with a polyvinyl chloride cross-linked gel content of 50%. piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com