Centrifugal rinsing and drying machine for magnetic materials

A technology of magnetic materials and drying machines, applied in dryers, non-progressive dryers, drying solid materials without heating, etc., can solve problems such as low work efficiency, inconvenient handling, and poor results, and achieve work High efficiency, good effect and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

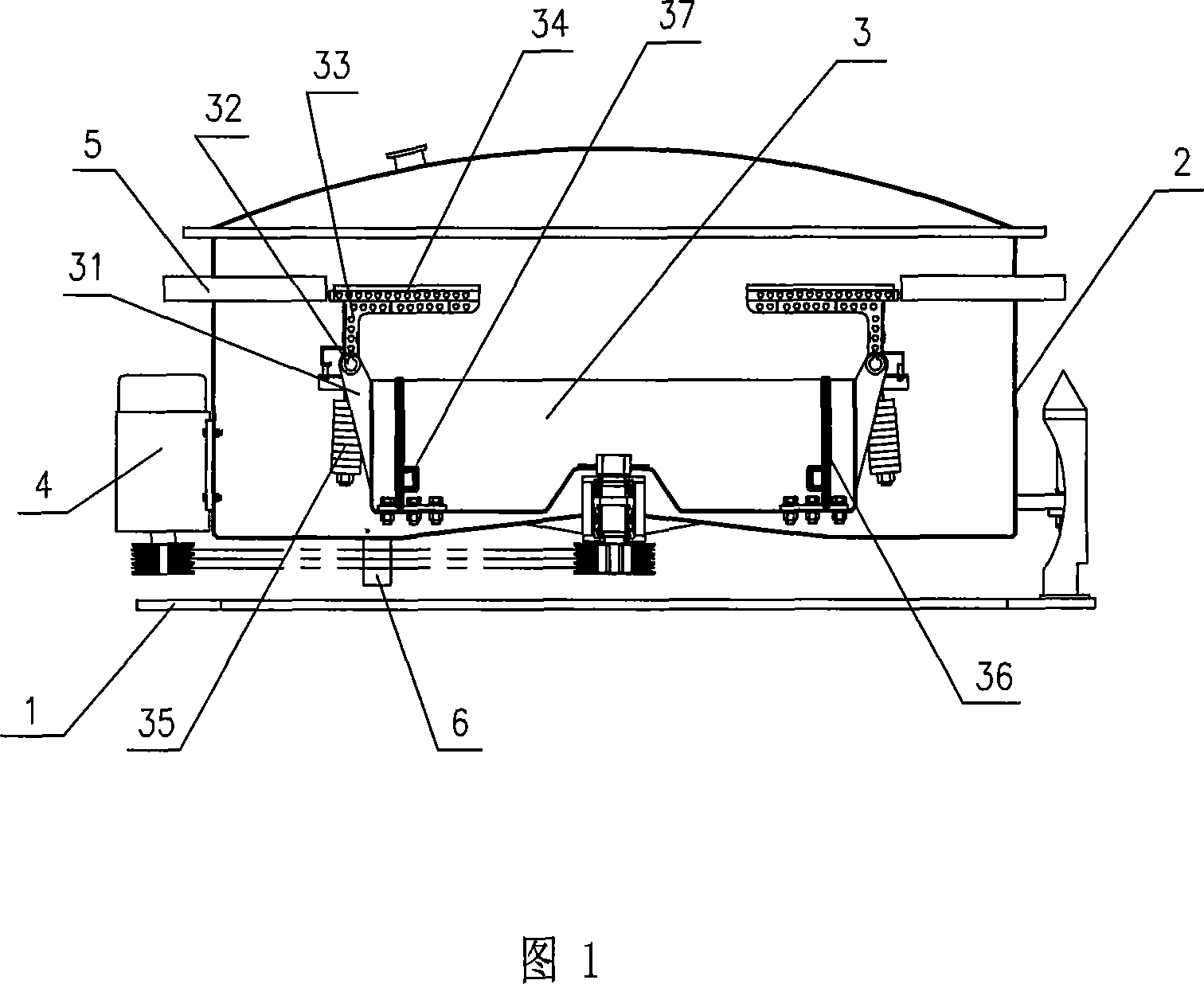

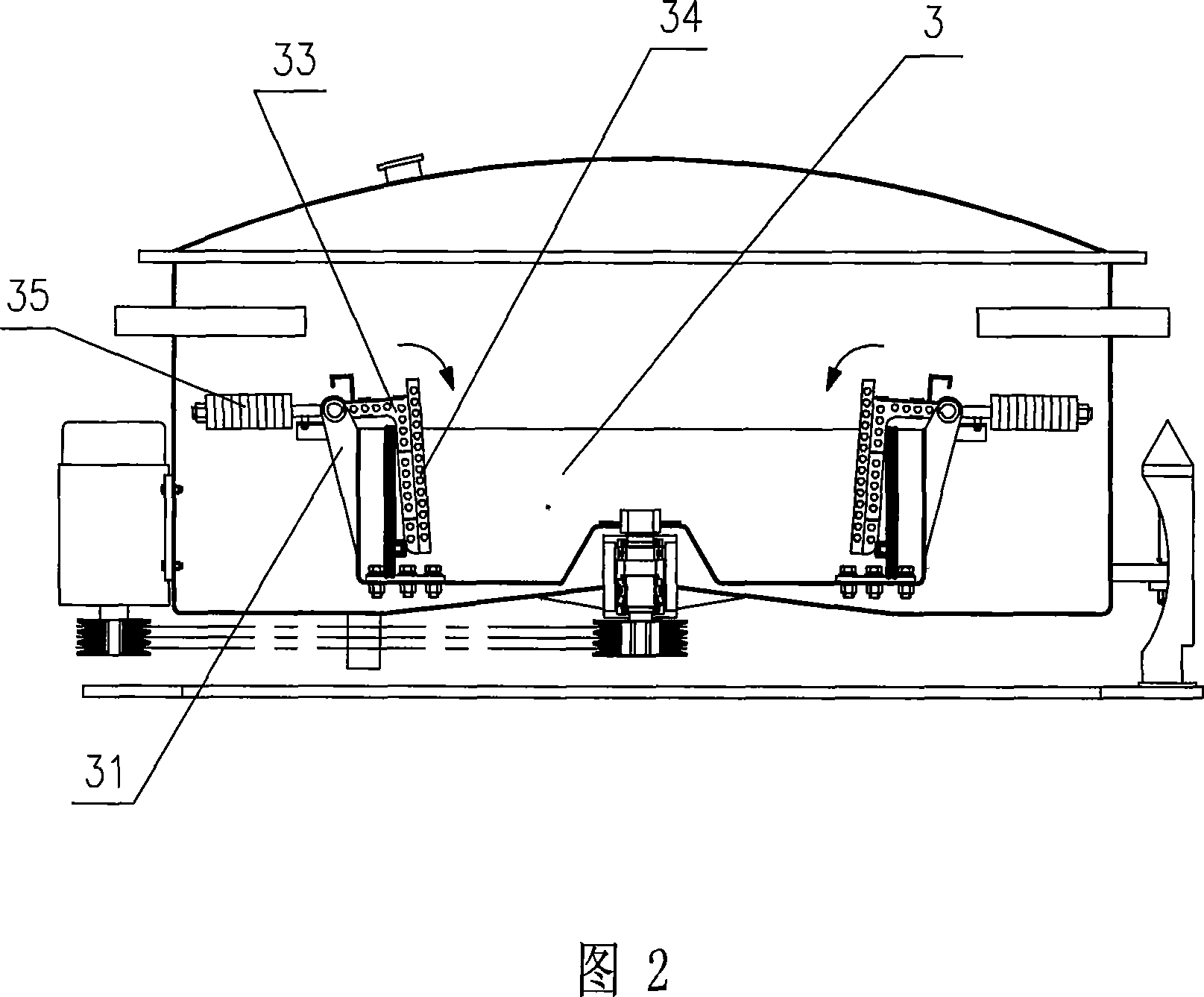

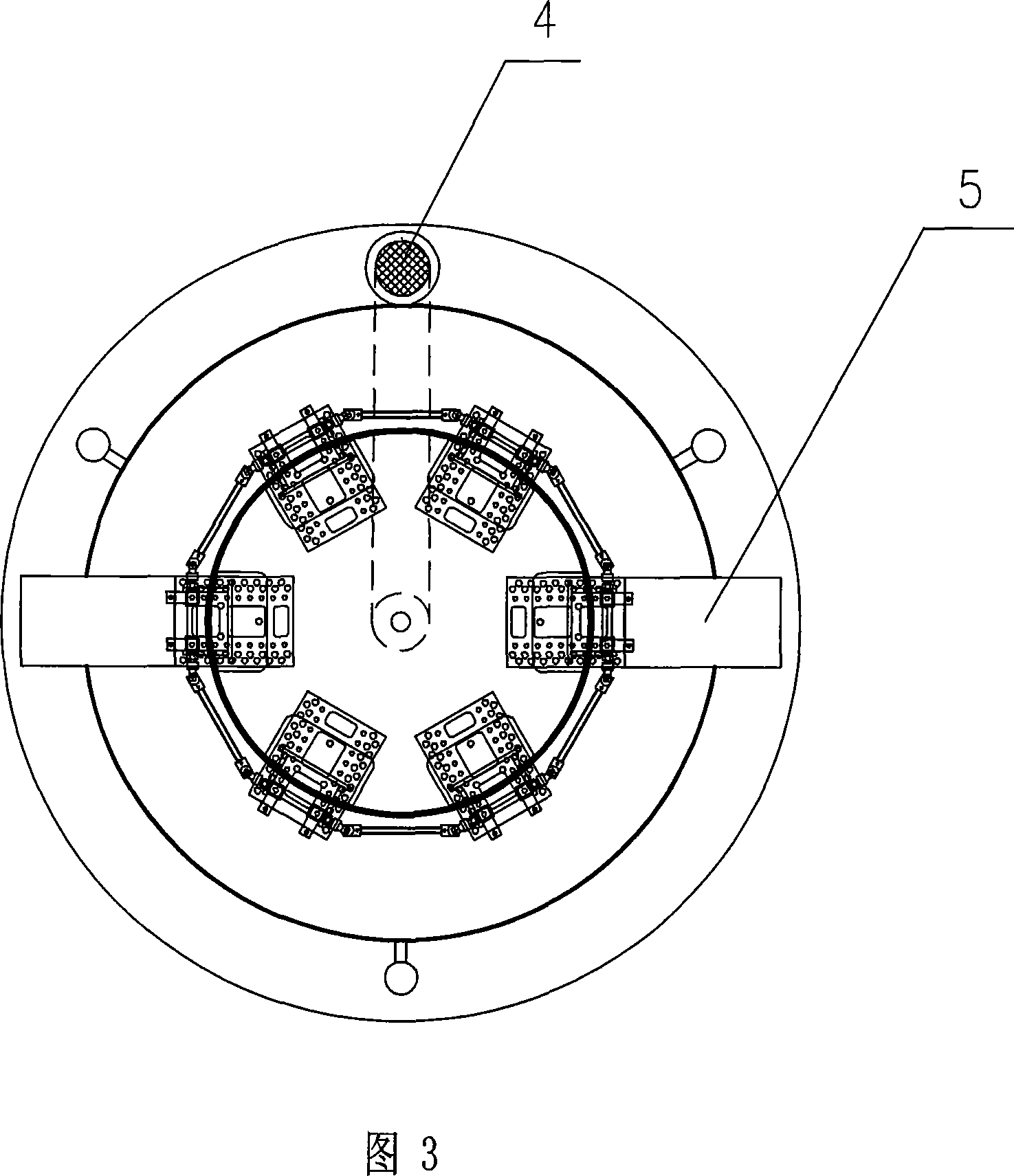

[0015] As shown in the figure, a centrifugal dryer for magnetic materials includes a base 1, a casing 2, and a motor 4. The casing 2 is arranged on the base 1 through the vibration-damping bracket on the base 1, and the bottom of the casing 2 is provided with a water outlet 6, The outer shell 2 is provided with a rotating inner shell 3 driven by a motor 4, the shell wall of the rotating inner shell 3 is provided with mesh holes, and six vertical supports 31 are evenly and symmetrically arranged on the shell wall around the central axis of the rotating inner shell 3, Each bracket 31 is composed of two corresponding bracket pieces with shaft holes. A rotating shaft 32 is provided through the shaft holes. The rotating shaft 32 is fixedly connected with a counterweight 35 and an inverted L-shaped material box frame 33. The weight block 35 hangs below the rotating shaft 32, and the material box frame 33 stands on the rotating shaft 32; the upper plane of the inverted L-shaped materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com