Mounting fixing mechanism for plough engine

A technology for fixing mechanisms and engines, which is applied to agricultural machinery and implements, and the chassis and applications of agricultural implements. It can solve the problems of easy aging and easy cracking of engine plastic mounting plates, and achieve reduced maintenance costs and good fixation and guidance. , enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

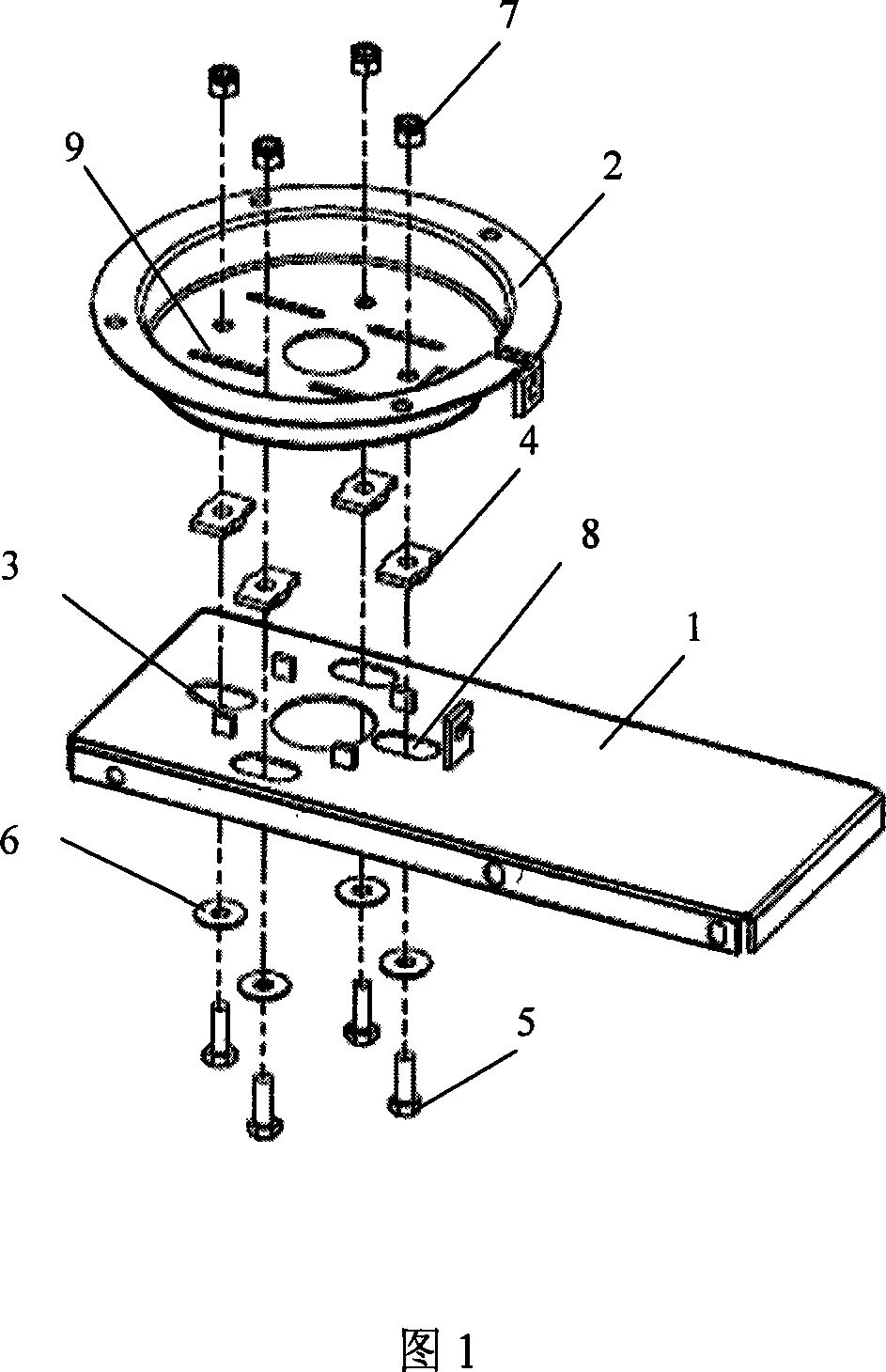

[0011] As shown in the figure, the engine installation and fixing mechanism of the plow machine includes an upper cover plate 1, an engine metal mounting plate 2, a slider 3, a gasket 4, a bolt 5, a flat pad 6 and an insert nut 7; There are four sliding blocks 3 for reducing friction, and the positions of the sliding blocks 3 correspond to the four sliding block grooves 9 on the metal mounting plate 2 of the engine, and the notch length of a single sliding block groove 9 is slightly longer than the length of the sliding block 3 ; Four bolts 5 and four insert nuts 7 correspond to the upper cover plate through holes 8 on the upper cover plate 1 and the screw holes on the engine metal mounting plate 2, and the engine metal mounting plate 2 is connected with the upper cover plate 1; The width of cover plate through hole 8 is equal to the diameter of bolt 5, and the length is 2-3 times of the diameter of bolt 5; The gasket 4 separates the upper cover plate 1 from the metal mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com