Pneumatic flexible ball joint based on arc pneumatic cylinder

A pneumatic cylinder and ball joint technology, applied in the field of ball joints, can solve the problems of poor rigidity, unreasonable structure, and difficult precise control of robot ball joints, and achieve good motion effects, small size, and flexible movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

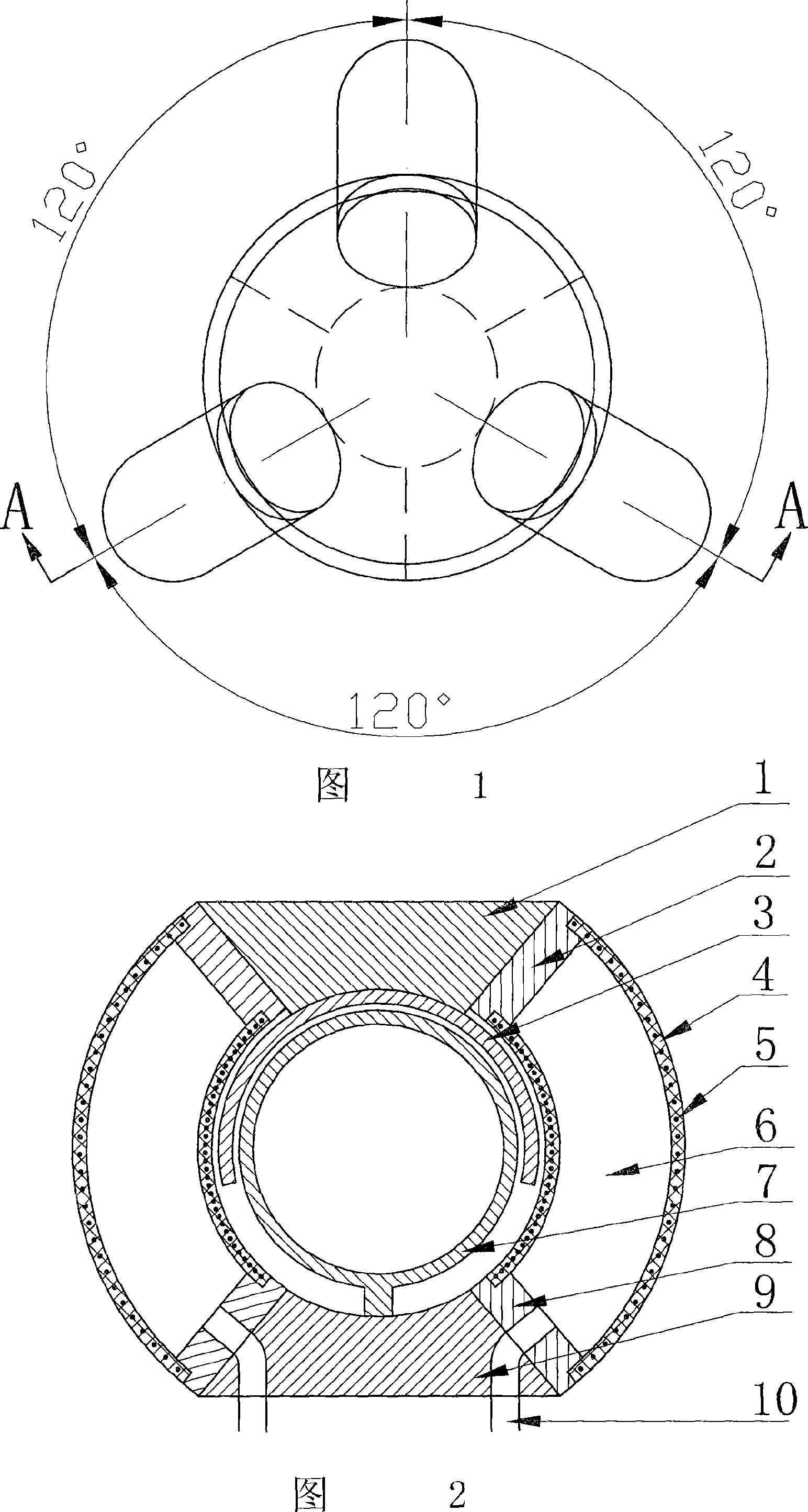

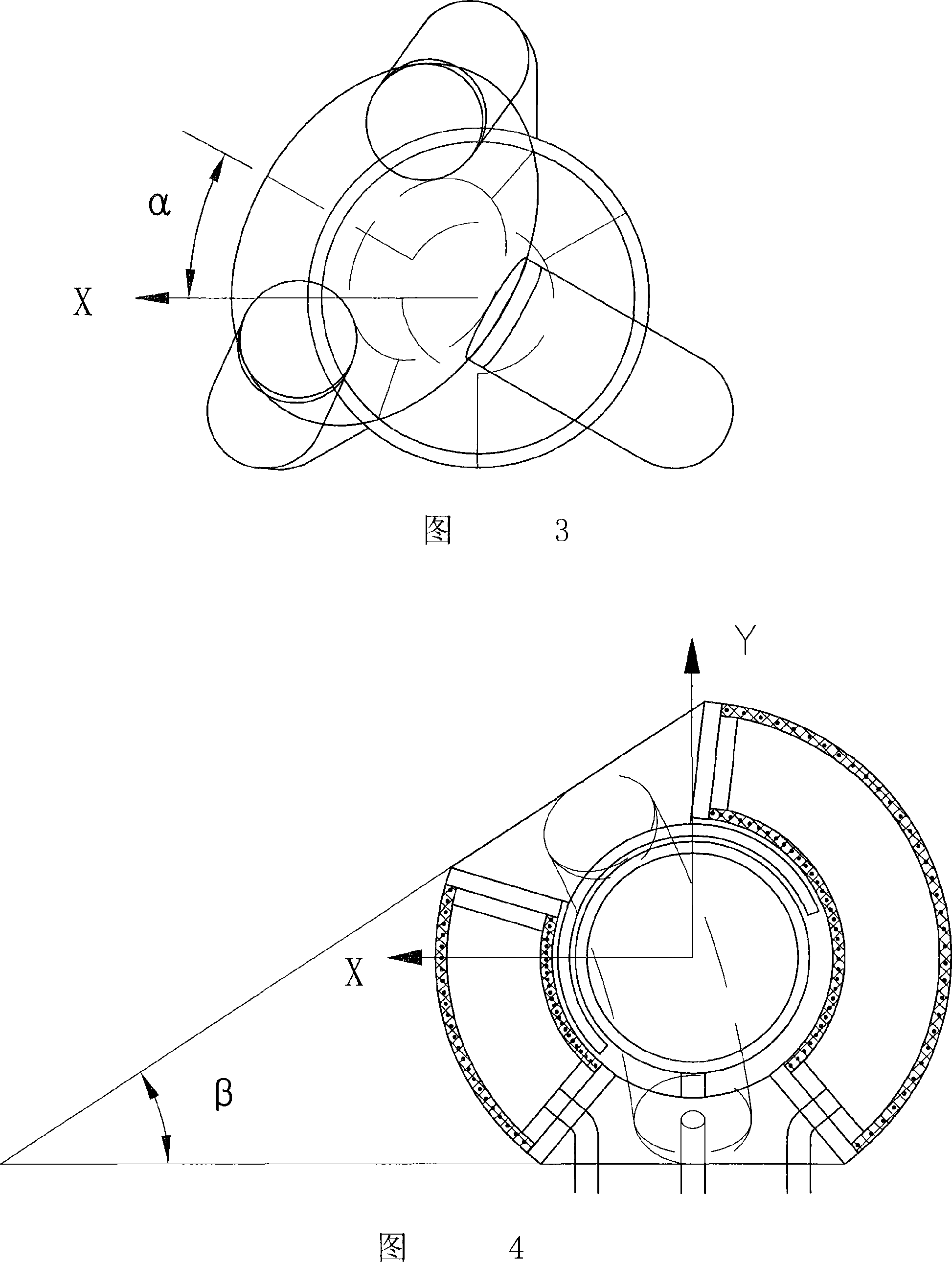

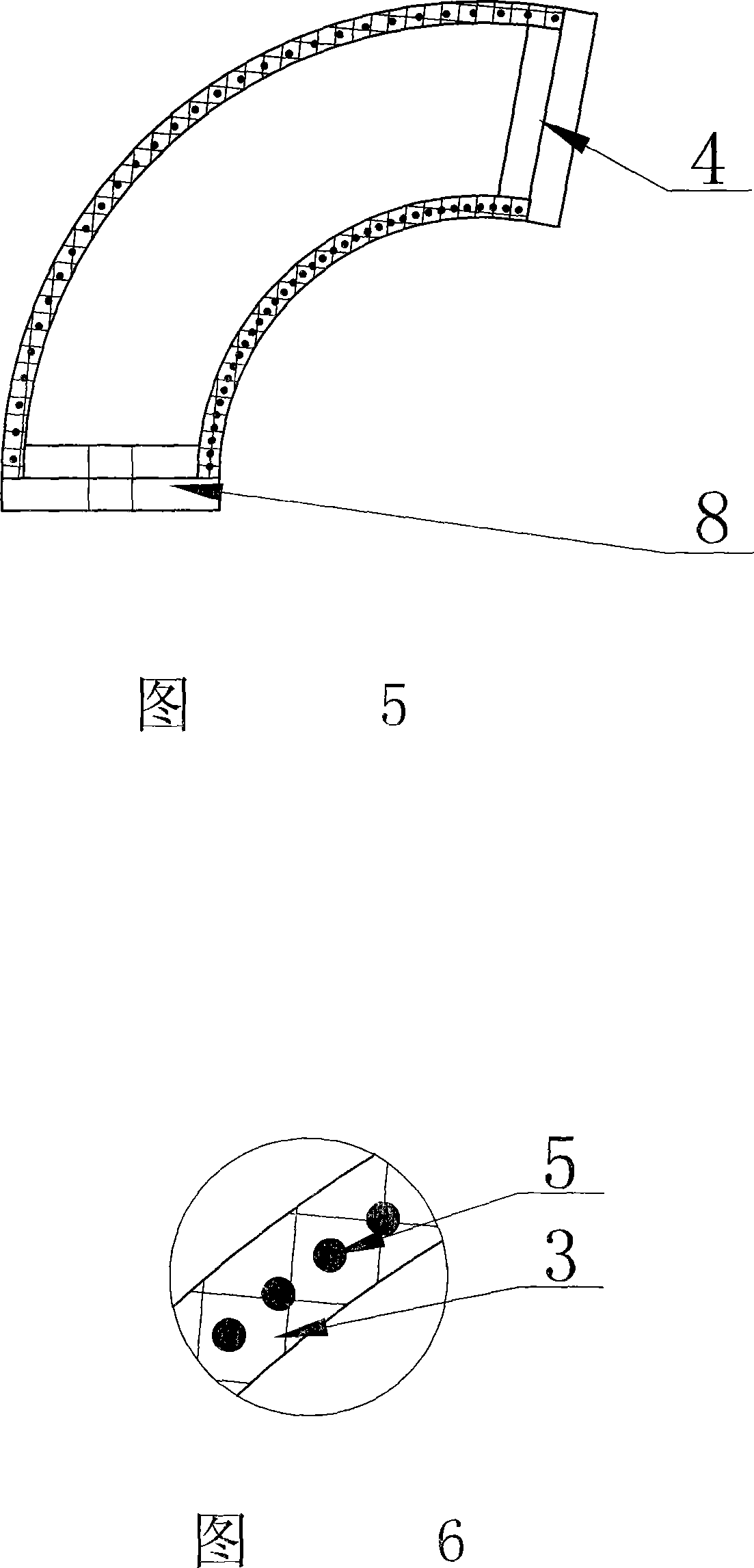

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Referring to Figures 1 to 5, a pneumatic flexible ball joint based on an arc-shaped pneumatic cylinder consists of three arc-shaped pneumatic flexible cylinders 6, a first end cover 8, a second end cover 2, an upper turntable 1, and a lower fixed plate 9 , hemispherical shell 3, spherical shell 7 and air pipe 10, the upper and lower ends of the three arc-shaped pneumatic flexible cylinders 6 are respectively sealed with the second end cover 2 and the first end cover 8, and the arc-shaped pneumatic flexible cylinders are due to their The inherent arc shape can ensure that it can extend or shrink along the arc during rotation; the first end cover 8 is fixedly connected with the lower fixed plate, and the first end cover 8 has a through hole to communicate with the outside atmosphere; the second end cover 2 is closed and fixedly connected to the upper turntable; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com