Non-coupling two-dimension moving one-dimension turning three-freedom spatial parallel mechanism

A technology with a degree of freedom and no coupling, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as complex structures, and achieve broad application prospects and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

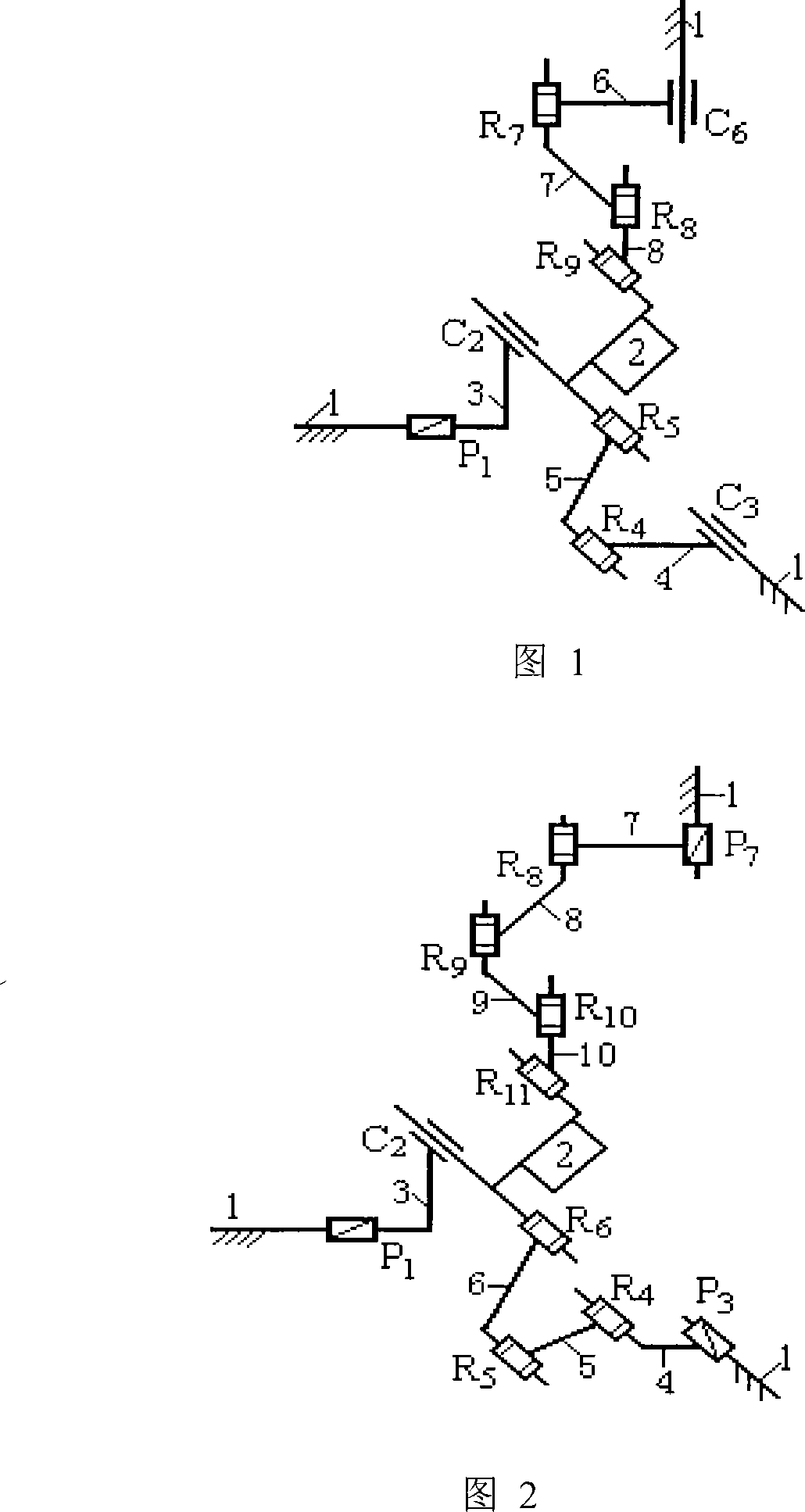

[0022] An uncoupled two-movement-rotation three-degree-of-freedom space parallel mechanism consists of a static platform 1, a dynamic platform 2, and three branches connecting the static platform 1 and the dynamic platform 2. Its specific structure is shown in Figure 1: the first Between the branch road from the static platform 1 to the moving platform 2 is a moving pair P 1 and one with the mobile vice P 1 Vertical Cylindrical Vice C 2 It is formed in series, and the two kinematic pairs are connected by component 3; the second branch is formed by a cylindrical pair C between the static platform 1 and the dynamic platform 2 3 and with this cylinder vice C 3 Two rotating pairs R with parallel axes 4 and R 5 The two adjacent kinematic pairs are connected in sequence through component 4 and component 5. The sequence and configuration relationship of the kinematic pairs from the static platform 1 to the dynamic platform 2 in this branch is C 3 / / R 4 / / R 5 ; The third branch...

Embodiment 2

[0025] A non-coupling two-movement-rotation three-degree-of-freedom space parallel mechanism consists of a static platform 1, a moving platform 2 and three branches connecting the two platforms. The specific structure is shown in Figure 2. Among them, the first branch is from the static platform 1 to the moving platform 2 by a mobile pair P 1 and one with the mobile vice P 1 Vertical Cylindrical Vice C 2 It is connected in series, and the two kinematic pairs are connected by a component 3; the second branch is from the static platform 1 to the moving platform 2 by a moving pair P 3 and three axes with which the moving pair P 3 Parallel rotary joint R 4 , R 5 and R 6It is formed in series, and the sequential kinematic pairs are connected by members 4, 5 and 6 respectively. The sequence and configuration relationship of the kinematic pairs from the static platform 1 to the dynamic platform 2 in this branch is P 3 / / R 4 / / R 5 / / R 6 ; The third branch is from the static p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com