Tire uniformity testing method

A measurement method and uniformity technology, applied in the field of tire quality inspection, can solve the problems of lack of systematic theoretical support and complete implementation methods, one-sided errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

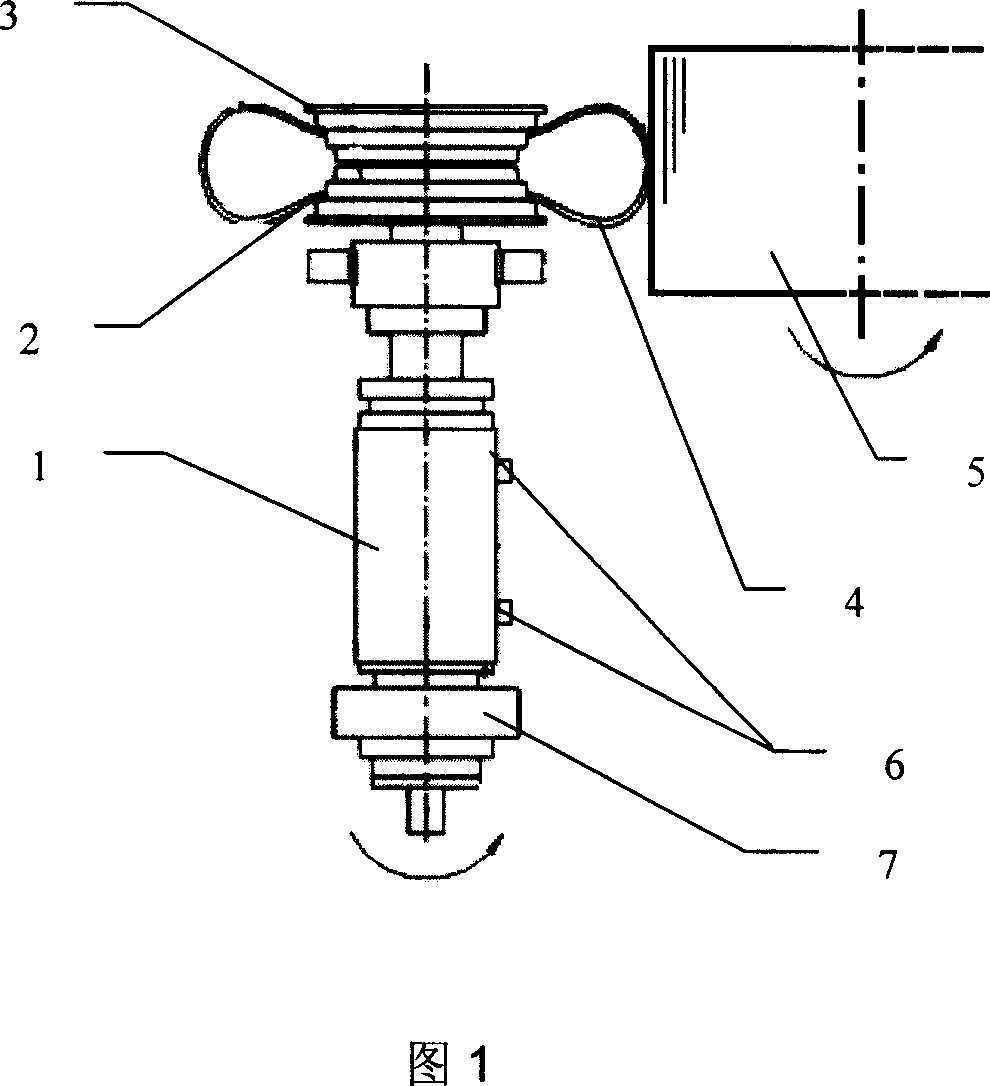

[0052] In Example 1, the tire uniformity measurement method uses the tire uniformity test device shown in FIG. 1. Wherein, the housing of the main shaft 1 does not rotate and has a supporting point, so that the main shaft 1 is in a suspended and semi-free state.

[0053] In the process of tire uniformity measurement, the spindle 1 will vibrate slightly, the sensor 6 is close to the outer shell of the spindle 1, and the sensor 6 will detect the vibration of the spindle.

[0054] Except for the main shaft part of the housing, the upper rim 3 can be rotated freely. The upper and lower rims are used to simulate the hub of the wheel, and play the role of clamping the tire and preventing the tire from deflating after inflation.

[0055] The axis of the load wheel 5 is always parallel to the axis of the main shaft 1, the material of the load wheel 5 is uniform, the geometric shape is symmetrical, and it can move horizontally to the left and right.

[0056] In the test, the load wheel 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com