Silicon carbide-containing particle, method of manufacturing a silicon carbide-based sintered object, silicon carbide-based sintered object, and filter

A technology containing silicon carbide particles and silicon carbide, which is applied in membrane filters, chemical instruments and methods, filtration and separation, etc., and can solve problems such as catalyst support layer peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Next, the present invention will be described based on examples.

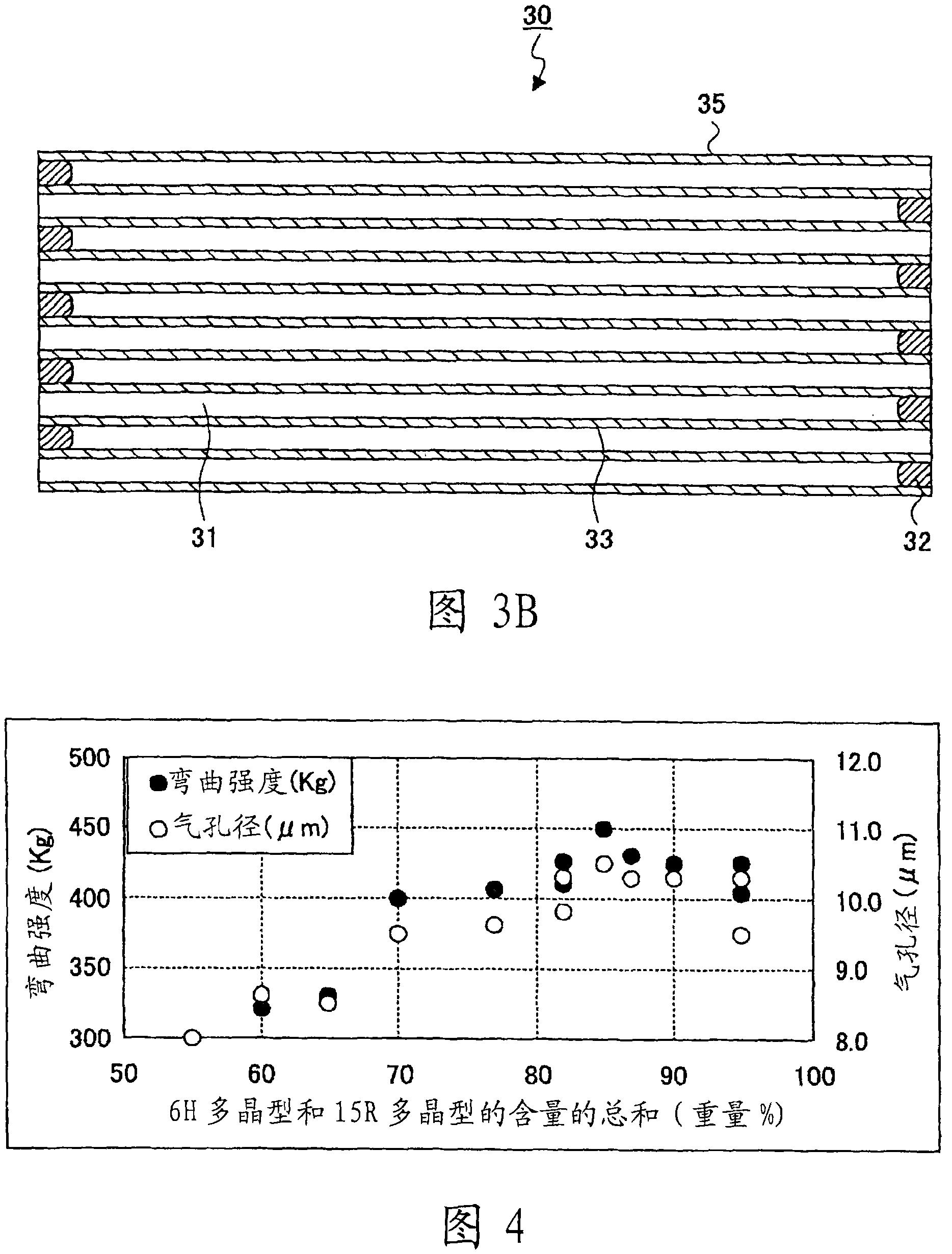

[0076] As shown in Table 1, using 12 kinds of silicon carbide-containing particles whose abundance ratios of 3C, 4H, 6H and 15R polymorphs in silicon carbide were adjusted, samples of silicon carbide sintered bodies were produced according to the above-mentioned procedures (Example 1 to 9 and comparative examples 1 to 3).

[0077] [Table 1]

[0078]

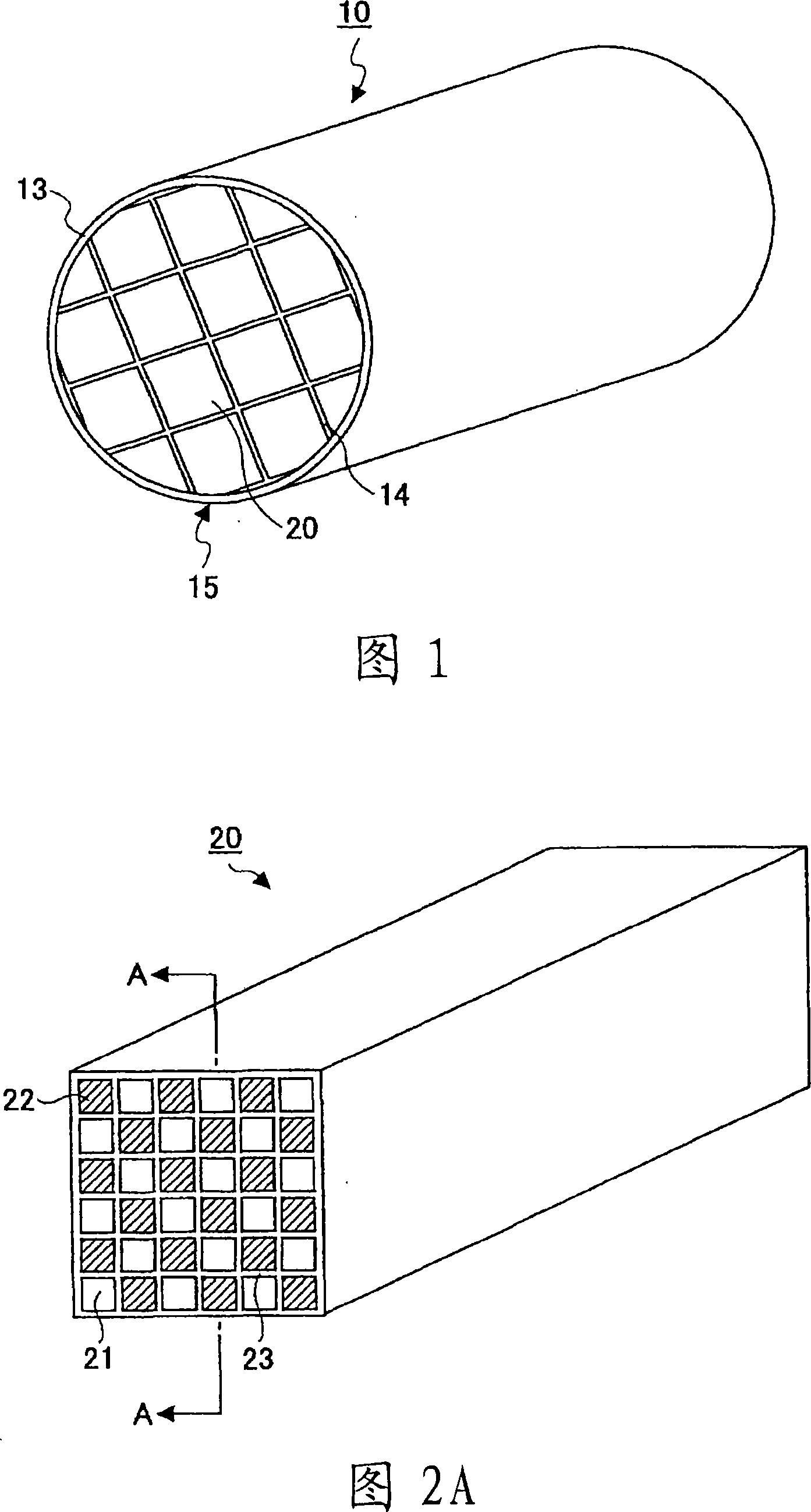

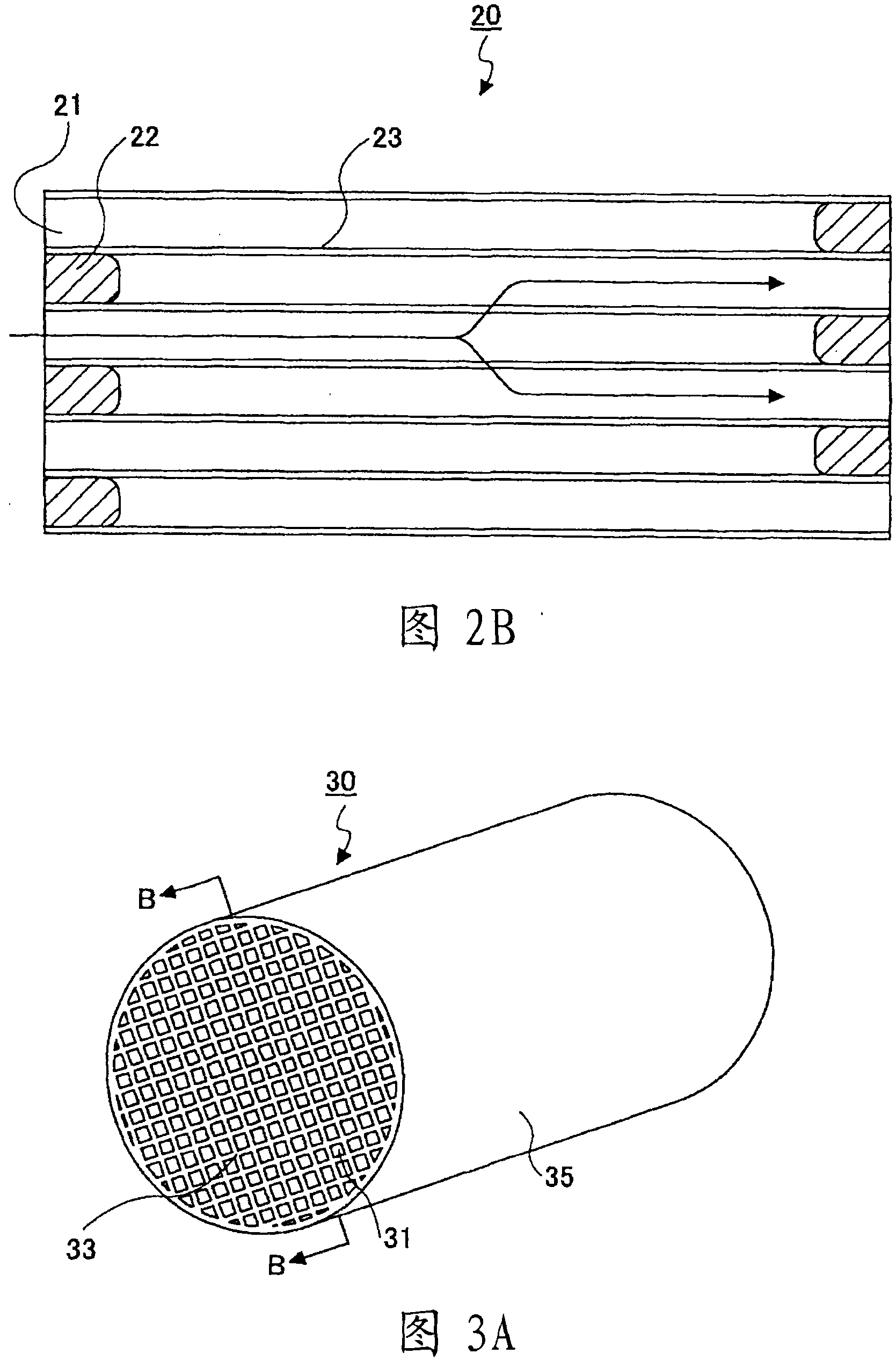

[0079] In addition, the sample of the silicon carbide sintered body is a honeycomb-shaped silicon carbide sintered body ( Hereinafter referred to as "honeycomb filter"). In this embodiment, the shape of the cross-section of each hole perpendicular to the length direction of the hole is a square. Also, the size of the honeycomb filter was 34.3 mm×34.3 mm×150 mm (hereinafter referred to as "honeycomb filter A"). The temperature for firing the silicon carbide-containing particles is 2200° C., and the time for firing the silicon carbide-containing partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com