Multi-metal part additive manufacturing device and method combining femtoseconds and traditional laser

An additive manufacturing and multi-metal technology, applied in the field of multi-metal parts additive manufacturing devices, can solve the problems of poor interface performance, limited printing speed, easy delamination, etc., to avoid cracking at the junction, fast speed, and avoid cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

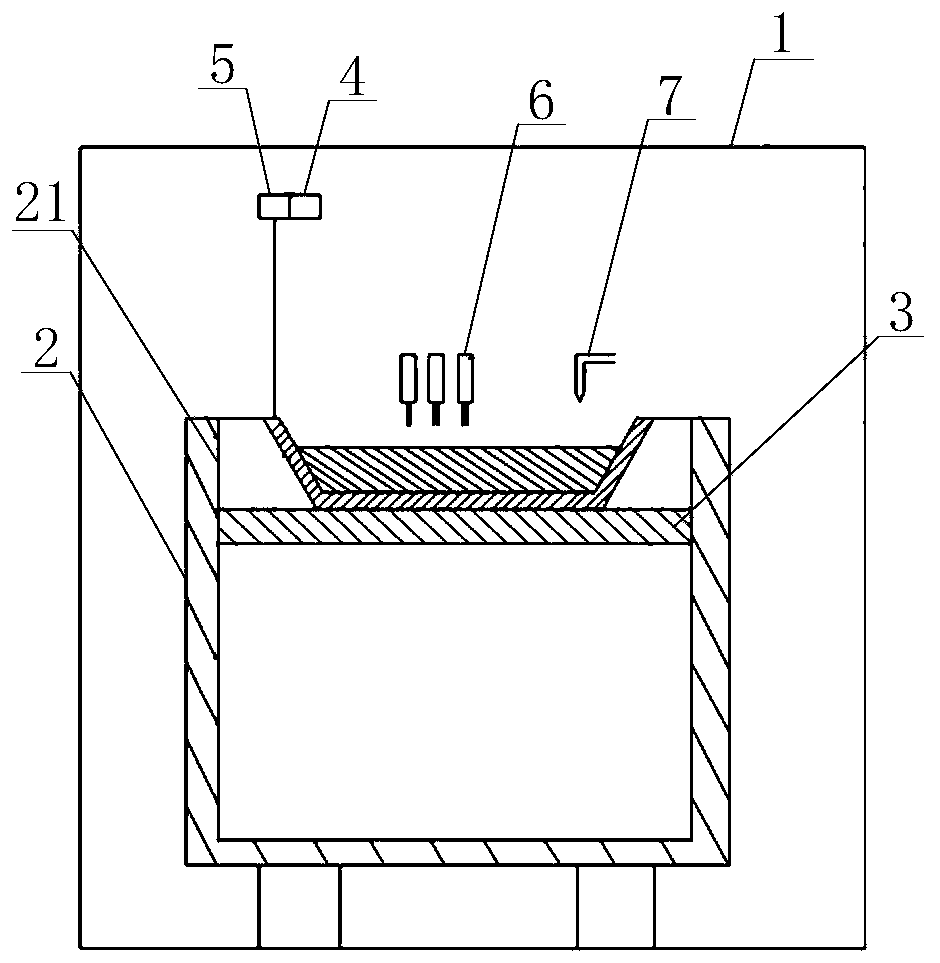

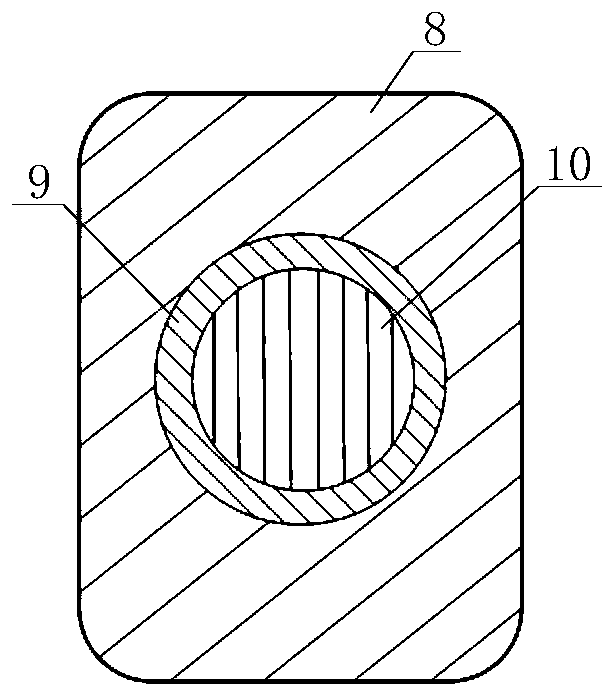

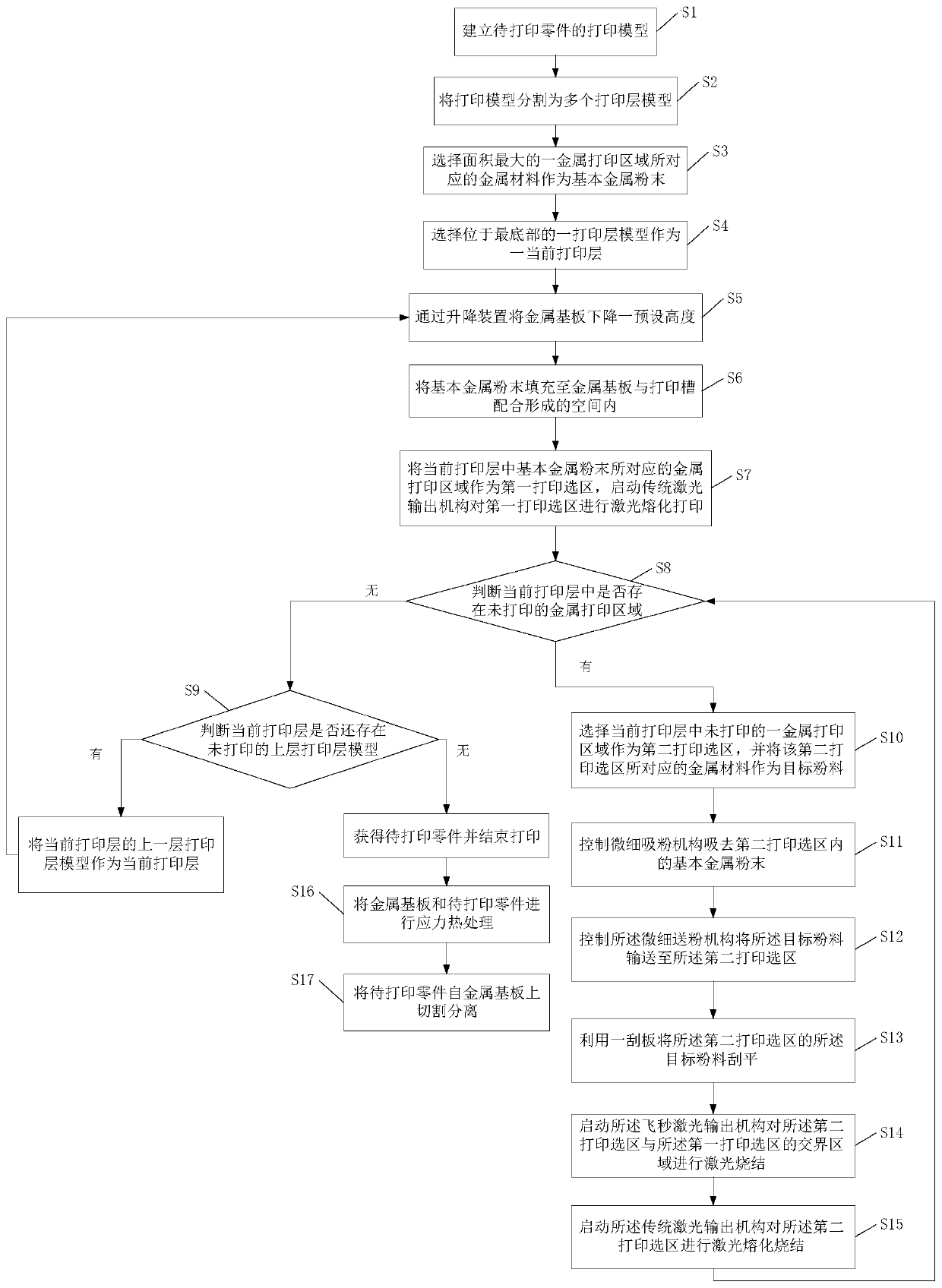

[0043] According to the attached Figure 1 ~ Figure 3 , Give the preferred embodiments of the present invention and describe them in detail, so as to better understand the functions and characteristics of the present invention.

[0044] See figure 1 with figure 2 , A multi-metal parts additive manufacturing device combining femtoseconds and traditional lasers according to an embodiment of the present invention includes an additive manufacturing device body. The additive manufacturing device body includes a printing chamber 1, a worktable 2, and a lift Device, a metal substrate 3, a traditional laser output mechanism 4 and a PLC controller; the workbench 2 is set in the printing chamber 1, the workbench 2 forms a printing slot 21, the shape of the metal substrate 3 matches the printing slot 21 and It can be lifted and fixed in the printing slot 21 by a lifting device; the traditional laser output mechanism 4 is arranged or partially arranged above the metal substrate 3; the PLC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com