A kind of ceramic matrix composite material and its preparation method and application

A composite material and ceramic-based technology, which is applied in the direction of mechanical equipment, machine/engine, engine components, etc., can solve the problems of inability to guarantee the thermal stability of the ceramic matrix, inability to use it for a long time, poor high-temperature thermal stability, etc., and achieve flexible composition design High performance, excellent thermal stability, good mechanical strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

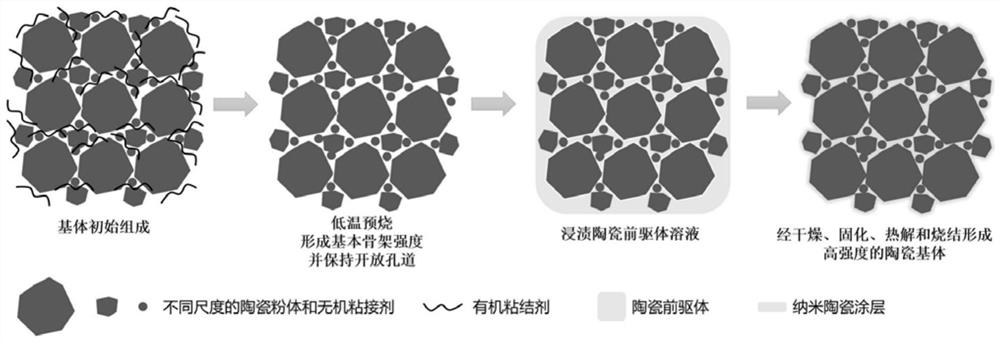

Method used

Image

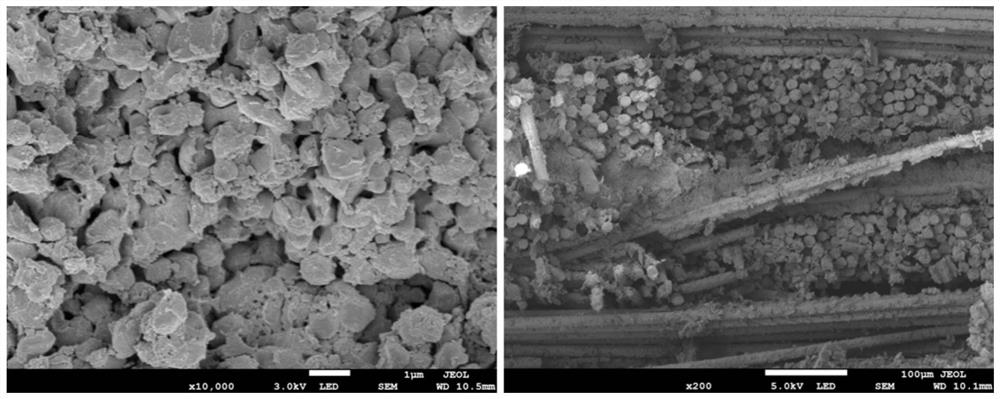

Examples

Embodiment 1

[0043] A kind of ceramic matrix composite material, its preparation method comprises the following steps:

[0044] 1) Add 10g of polyvinyl alcohol and 5g of sodium silicate into 200mL of water, stir to dissolve, and then add 20g of D 50 20nm alumina powder, 40g of D 50 200nm alumina powder and 40g of D 50 Alumina powder of 2 μm is ball milled to obtain ceramic slurry;

[0045] 2) Brush the ceramic slurry onto the alumina fiber cloth, and then dry it in an oven at 60°C for 2 hours to obtain a prepreg cloth, then stack the prepreg cloth into a metal mold, and place the prepreg cloth under a pressure of 2MPa and a temperature of 100°C The composite material green body was obtained by laminating under the conditions for 1 hour, and then the composite material green body was cured in an oven at 200°C for 1 hour, then pyrolyzed in a muffle furnace at 500°C for 6 hours, and pre-fired at 900°C for 2 hours to obtain a pre-fired sample;

[0046] 3) Put the pre-fired sample in a pres...

Embodiment 2

[0050] A kind of ceramic matrix composite material, its preparation method comprises the following steps:

[0051] 1) Add 10g of hydroxymethyl cellulose and 50g of silica sol with a mass fraction of 20% into 200mL of water, stir to dissolve, and then add 50g of D 50 200nm alumina powder and 50g of D 50 Alumina powder of 1 μm is ball milled to obtain ceramic slurry;

[0052] 2) Brush the ceramic slurry onto the alumina fiber cloth, and then dry it in an oven at 60°C for 2 hours to obtain a prepreg cloth, then stack the prepreg cloth into a metal mold, and place the prepreg cloth under a pressure of 2MPa and a temperature of 100°C The composite material green body was obtained by laminating under the conditions for 1 hour, and then the composite material green body was cured in an oven at 200°C for 1 hour, then pyrolyzed in a muffle furnace at 500°C for 6 hours, and pre-fired at 900°C for 2 hours to obtain a pre-fired sample;

[0053] 3) Put the pre-fired sample in a pressure...

Embodiment 3

[0062] A kind of ceramic matrix composite material, its preparation method comprises the following steps:

[0063] 1) Add 10g of polyvinylpyrrolidone and 50g of aluminum sol with a mass fraction of 20% into 200mL of water, stir to dissolve, and then add 50g of D 50 200nm alumina powder and 50g of D 50 Alumina powder of 1.5 μm is ball milled to obtain ceramic slurry;

[0064] 2) Brush the ceramic slurry onto the alumina fiber cloth, and then dry it in an oven at 60°C for 2 hours to obtain a prepreg cloth, then stack the prepreg cloth into a metal mold, and place the prepreg cloth under a pressure of 2MPa and a temperature of 100°C The composite material green body was obtained by laminating under the conditions for 1 hour, and then the composite material green body was cured in an oven at 200°C for 1 hour, then pyrolyzed in a muffle furnace at 500°C for 6 hours, and pre-fired at 900°C for 2 hours to obtain a pre-fired sample;

[0065] 3) Put the pre-fired sample in a pressur...

PUM

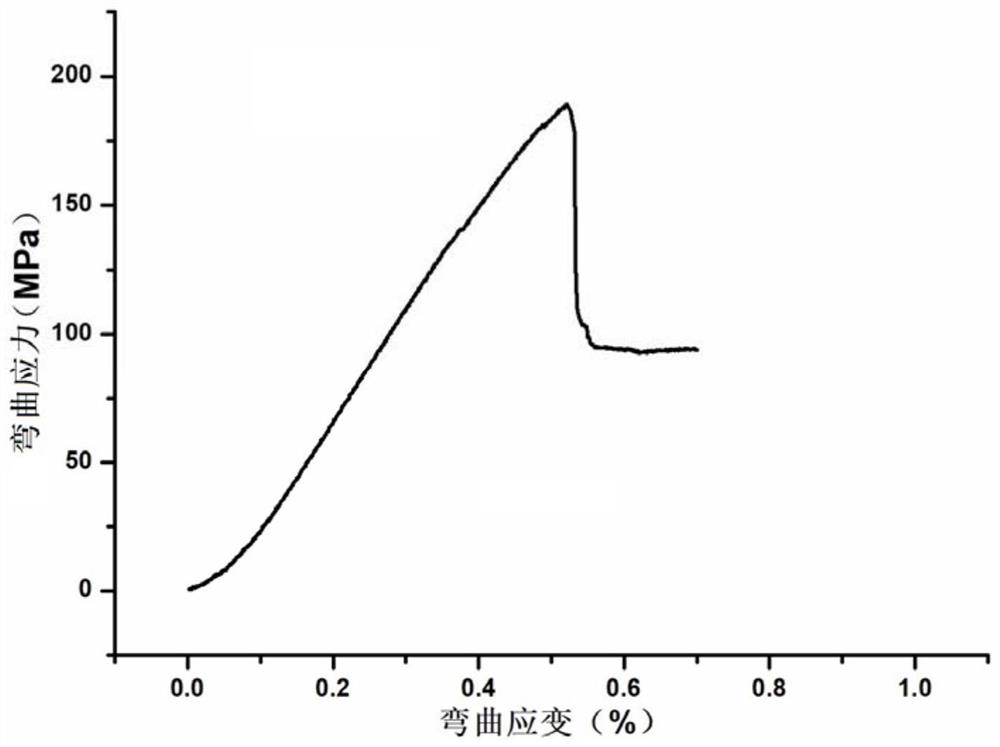

| Property | Measurement | Unit |

|---|---|---|

| bending stress | aaaaa | aaaaa |

| bending stress | aaaaa | aaaaa |

| bending stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com